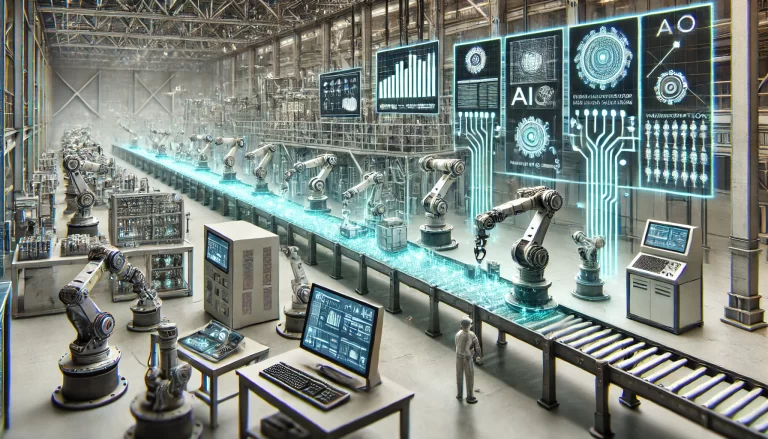

Artificial Intelligence (AI) is transforming many industries, and its impact on flow meters, instrumentation, and measurement automation is significant. By integrating AI with these technologies, the industry is moving towards smarter, more efficient, and highly adaptive systems. Below, we delve into how AI is shaping this field and explore potential future developments in greater detail.

1. Current Impact of AI on Flow Meters and Measurement Automation

1.1 Enhanced Accuracy and Efficiency

AI enhances the precision of flow measurement systems by providing:

- Real-time Calibration and Compensation: AI models can analyze and adjust for external factors such as temperature, pressure, and fluid properties. This reduces measurement errors and ensures reliable data under dynamic operating conditions.

- Anomaly Detection: By learning from historical and real-time data patterns, AI can detect abnormalities such as blockages, leaks, or sensor malfunctions. This reduces downtime and avoids costly failures.

1.2 Intelligent and Adaptive Systems

AI equips flow meters with advanced capabilities:

- Multi-Variable Analysis: Traditional flow meters often measure a single parameter, but AI enables simultaneous monitoring and interpretation of multiple variables such as flow rate, density, and viscosity. This holistic view ensures better control over the process.

- Self-Learning Systems: AI-powered devices can learn from their own data, improving their accuracy and performance over time. For instance, a flow meter can optimize its behavior in response to changes in fluid dynamics or system conditions.

1.3 Remote Monitoring and Predictive Maintenance

AI, combined with IoT (Internet of Things), facilitates:

- Remote Monitoring: Cloud integration allows users to access flow meter data in real time from anywhere, streamlining management and decision-making processes.

- Predictive Maintenance: AI algorithms analyze sensor and flow data to predict equipment failures before they happen. This prevents unexpected breakdowns, reduces maintenance costs, and extends the lifespan of instruments.

1.4 Process Optimization

AI optimizes industrial processes by:

- Energy Consumption Reduction: AI can adjust flow rates to achieve energy-efficient operation, reducing costs and environmental impact.

- Digital Twin Implementation: Digital twins are virtual replicas of physical devices. By integrating AI, flow meters can simulate and optimize fluid transport systems, improving overall operational efficiency.

2. Future Trends in AI-Driven Flow Meter Development

2.1 Greater Intelligence and Integration

The future flow meter will act as more than a measuring device; it will become an intelligent node in a fully integrated system. These devices will:

- Communicate seamlessly with other components in automated systems.

- Provide system-wide insights to improve industrial processes.

2.2 AI-Driven Real-Time Analysis and Decision-Making

- Edge Computing: AI algorithms embedded in flow meters will process data locally, enabling faster decision-making and reducing dependence on cloud systems.

- Autonomous Operations: AI-powered systems will dynamically adjust flow rates, pressure levels, and other parameters in real time without human intervention.

2.3 Self-Healing and Diagnostic Capabilities

AI will enable flow meters to:

- Self-Diagnose Issues: Identify internal problems, such as sensor drift or contamination, and notify operators or adjust settings accordingly.

- Self-Repair: Implement automated corrective actions, such as recalibration or data noise reduction, to maintain optimal functionality.

2.4 Focus on Sustainability

As industries prioritize sustainability, flow meters will play a critical role in:

- Minimizing Waste: AI will ensure precise fluid measurement, reducing overuse and waste.

- Monitoring Emissions: Advanced flow meters will track emissions and optimize processes to comply with environmental regulations.

2.5 Open Systems and Interoperability

Future AI-powered flow meters will operate on open, interoperable platforms, enabling:

- Cross-Device Communication: Collaboration across various devices and systems in industrial setups.

- Seamless Data Exchange: Sharing data in standardized formats for easier integration into larger industrial ecosystems.

2.6 Enhanced Human-Machine Interaction

Advanced technologies like Augmented Reality (AR) and Virtual Reality (VR) will combine with AI to:

- Provide interactive maintenance guides.

- Enable immersive training for technicians and engineers.

- Visualize complex flow data in an intuitive and accessible way.

Conclusion

AI is revolutionizing the landscape of flow meters and measurement automation. By enhancing accuracy, enabling predictive maintenance, and supporting intelligent, self-adaptive systems, AI is turning traditional instrumentation into indispensable tools for modern industries. The future promises further advancements, including fully autonomous operations, sustainability-driven designs, and enhanced interoperability.

As industries continue to embrace digital transformation, AI-powered flow meters will play an essential role in shaping a smarter, more efficient, and environmentally conscious future. These devices will not only measure flow but also provide actionable insights and optimize entire systems, heralding a new era in measurement and automation technology.