Activated coke flue gas desulfurization technology is an emerging dry flue gas desulfurization method that, due to its superior performance, is gradually becoming an important choice in the field of environmental protection in China.

This technology leverages the porous structure and strong adsorption properties of activated coke to remove sulfur dioxide (SO₂) and other harmful substances from flue gas through physical and chemical processes, thereby purifying the exhaust gas. Compared to traditional wet desulfurization technologies, activated coke flue gas desulfurization offers multiple advantages, such as a simpler process flow, high purification efficiency, minimal secondary environmental pollution, and the ability to recycle desulfurization by-products (such as sulfur), which promotes resource reuse and the development of a circular economy.

As a result, this technology not only aligns with China’s stringent environmental policies but also supports the national strategy of promoting green and sustainable development.

The Importance of the Material Circulation System

In activated coke flue gas desulfurization engineering, the material circulation system is the core component that ensures the stable operation of the system. The primary function of the material circulation system is to maintain the continuous flow and uniform distribution of activated coke during adsorption, regeneration, and desulfurization reactions, thereby avoiding local excess or deficiency. This ensures the efficiency of the desulfurization reaction and the long-term stable operation of the system. The efficiency and stability of this system largely depend on the accurate measurement and control of the material level within the silos.

Level measurement is a critical control parameter in the material circulation system. By monitoring the height and distribution of materials in the silo in real-time, it is possible to promptly adjust the supply and recovery of materials, preventing production interruptions or a decline in system efficiency caused by insufficient or excessive material levels. Selecting the appropriate level measurement instruments is particularly important given the different process requirements and site conditions. The following will provide an in-depth discussion of several key level measurement instruments and their applications in activated coke desulfurization engineering.

Vibration Rod Level Switch

The vibrating rod level switch, as a high-precision level measurement instrument, is widely favored for its innovative structural design and superior measurement accuracy. Particularly, the Tube-11 vibrating rod level switch, a domestic brand, has performance levels that have nearly matched or even surpassed some imported brands.

The core advantage of the Tube-11 vibrating rod level switch lies in its unique dual-tube probe design. This nested inner and outer structure not only enhances the instrument’s resistance to material buildup and impact but also effectively avoids the common jamming issues found in traditional tuning fork level switches. The device can accurately measure under conditions with a medium density as low as 0.02 g/cm³, making it suitable for monitoring the vast majority of solid particles. Consequently, in various complex industrial environments, the Tube-11 vibrating rod level switch has demonstrated exceptional adaptability. Its stability and precision have been highly recognized by users, especially in activated coke flue gas desulfurization engineering.

Additionally, under specific operating conditions, the vibrating rod level switch has demonstrated excellent anti-interference capabilities, maintaining stable measurement performance in environments with significant vibration, dust, and temperature fluctuations. These characteristics make it the preferred level measurement solution for the material circulation system in activated coke desulfurization engineering.

Rotary Paddle Level Switch

The rotary paddle level switch is widely used in various industrial level measurement scenarios due to its simple structure and low cost. However, its application in activated coke desulfurization engineering faces some challenges. While it is unaffected by environmental factors such as medium density, temperature, and humidity, the rotary paddle level switch can experience measurement inaccuracies when dealing with materials like activated coke, which tend to adhere easily. Issues such as material buildup and blade deformation can compromise its accuracy.

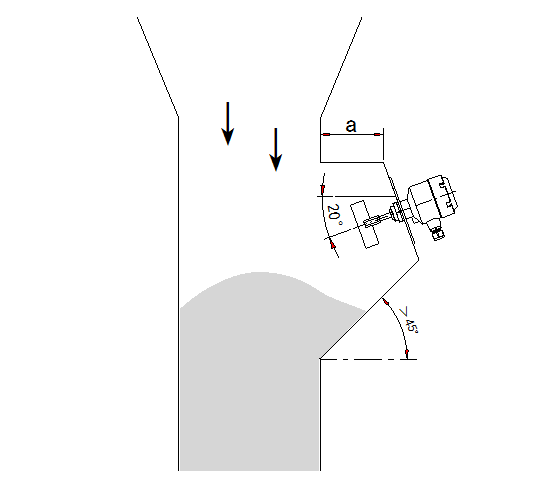

To address these issues, a reasonable installation method can partially improve the situation. It is generally recommended to install a recess or niche on the equipment to buffer the impact of the material’s weight, thereby reducing damage to the rotary paddle level switch. However, even with these measures, the measurement accuracy and lifespan of the rotary paddle level switch still struggle to meet the high demands of activated coke desulfurization engineering. Therefore, despite its lower cost, the use of rotary paddle level switches in such projects requires careful consideration.

Radar Level Meter

Radar level meters are high-precision instruments in the field of level measurement, particularly well-suited for use under complex and demanding conditions. Their operating principle involves emitting electromagnetic waves and receiving reflected wave signals, then accurately calculating the level height based on the time-of-flight principle. Radar level meters offer strong measurement continuity, high accuracy, and are unaffected by the properties of the material. This makes them especially suitable for conditions involving materials like activated coke, which are adhesive, dusty, and have irregular surfaces.

Frequency modulated radar level meters are a high-performance product within the radar level meter category, designed to enhance signal-to-noise ratio and anti-interference capability, allowing for stable and accurate measurements in complex industrial environments. Additionally, the instrument’s aiming device can significantly improve the reliability of measuring sloped solid materials, preventing measurement errors caused by irregular material surfaces or strong material adhesiveness.

In activated coke desulfurization engineering, radar level meters are particularly well-suited for measuring the material level in regeneration towers. The conditions within a regeneration tower are complex, with variable material characteristics, placing high demands on level measurement instruments. The high-precision measurement and strong anti-interference capabilities of radar level meters enable precise monitoring of material distribution in such environments, ensuring the stability and efficiency of the regeneration process.

Conclusion

In summary, the domestic vibrating rod level switch is the preferred solution for measuring activated coke levels in desulfurization engineering, offering high precision and strong adaptability to meet the demands of most operating conditions. For more complex level measurements, such as in regeneration towers, radar level meters should be prioritized due to their high precision, anti-interference capabilities, and independence from material properties.

While rotary paddle level switches are cost-effective, their application in activated coke desulfurization engineering requires caution. Due to their relatively low measurement accuracy and susceptibility to material characteristics, they are generally not recommended for use in critical process stages.

By carefully selecting and combining level measurement instruments, activated coke desulfurization engineering can achieve efficient and stable operation, contributing to improved desulfurization effectiveness, reduced environmental pollution, and the advancement of environmental protection efforts in China.