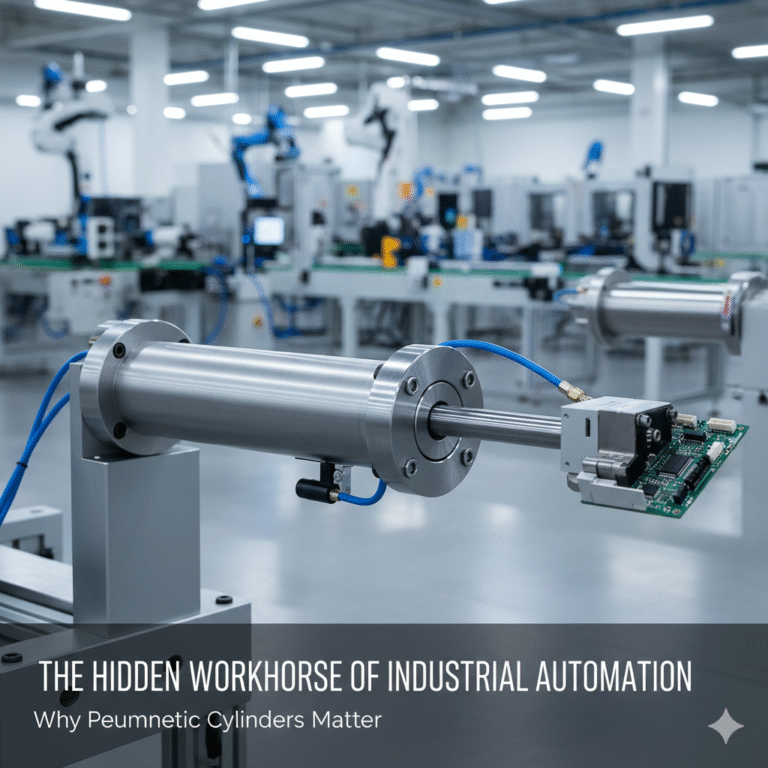

In modern automated production lines, many precise and repetitive mechanical actions rely on a component that rarely attracts attention: the pneumatic cylinder.

From stamping presses and robotic arms to packaging systems and electronic assembly equipment, pneumatic cylinders silently convert compressed air into controlled motion, forming the muscle system of machinery.

1. What Is a Pneumatic Cylinder?

A pneumatic cylinder is an actuator that converts compressed air energy into linear or rotary motion. Compressed air, controlled by solenoid valves, enters the cylinder chambers to move a piston forward or backward, enabling actions such as pushing, pulling, lifting, clamping, positioning, or rotating.

Key Advantages

Simple Structure: No complex oil circuits or cooling systems.

Fast Response: Suitable for high-frequency operations.

Clean and Low Maintenance: No oil contamination, easy to replace.

Cost-Effective: Low installation and operating cost.

Compared to electric actuators, pneumatic cylinders are lighter and simpler. Compared to hydraulic systems, they are cleaner, safer, and easier to maintain.

2. How a Pneumatic Cylinder Works

A typical cylinder consists of:

Cylinder barrel

Piston

Piston rod

End caps

Seals

When compressed air enters one side of the cylinder chamber, the piston moves and drives the piston rod. Reversing the air supply changes the motion direction.

With additional components, such as magnetic sensors, flow control valves, or proportional valves, cylinders can achieve:

Adjustable speed and stroke

Smooth cushioning and positioning

Real-time motion monitoring

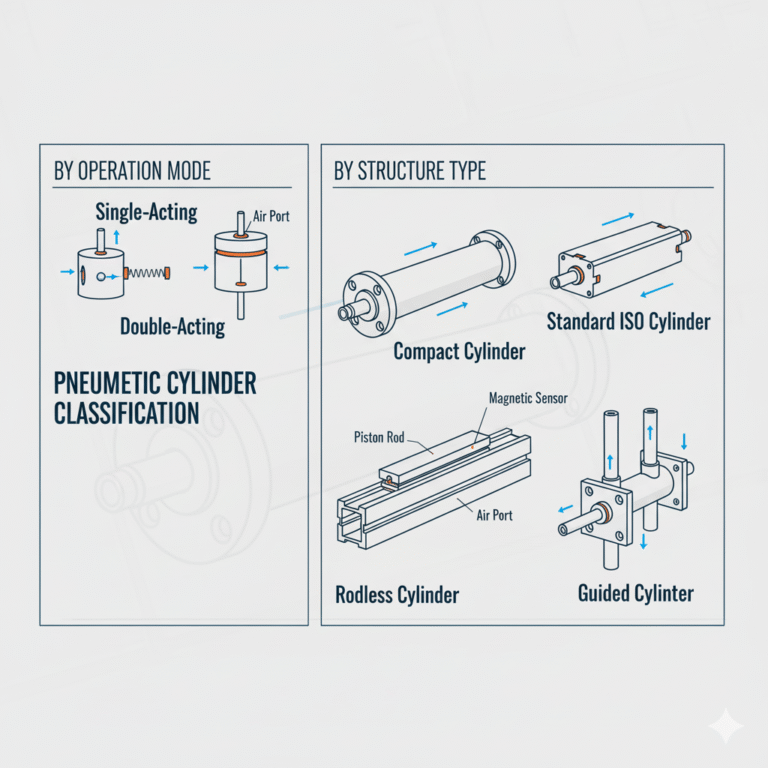

3. Classification and Structural Types

| Category | Type | Features | Typical Applications |

|---|---|---|---|

| By Operation Mode | Single-Acting | Air-driven one way, spring return | Ejection, limiting |

| Double-Acting | Air-driven in both directions, higher force | General industrial automation | |

| Rodless Cylinder | Magnetic/slider transmission, long stroke | Space-constrained systems | |

| Rotary/Swivel Cylinder | Outputs angular displacement | Flipping, rotating | |

| By Structure | Standard Round/ISO Cylinder | Universal and easy to replace | General machinery |

| Thin/Compact Cylinder | Space-saving | Packaging & assembly | |

| Guided Cylinder | High anti-side-load capability | Positioning and clamping | |

| Cushioned Cylinder | Impact reduction | High-speed movement systems | |

| By Environment | Stainless Steel Cylinder | Rust and corrosion resistance | Food & pharmaceutical |

| Explosion-Proof | Safety protection | Chemical / mining | |

| High/Low Temperature | Special seals | Metallurgy / cold storage |

4. Key Factors in Cylinder Selection

Choosing a cylinder is a system-level decision. The main considerations include:

(1) Force and Load

F=P×A

Where P is the air pressure (e.g., 0.4 MPa) and A is the effective piston area.

Include friction, inertia, and safety factor (typically 1.5× recommended).

(2) Stroke and Space

Stroke should exceed the required travel slightly.

In limited space, consider compact or rodless cylinders.

(3) Speed and Control Accuracy

Typical speed: 50–500 mm/s

Use throttle valves and cushions for smooth motion

Magnetic switches enable position feedback and closed-loop control

(4) Working Environment

| Condition | Recommended Solution |

|---|---|

| High Temperature | Fluororubber sealing |

| Low Temperature | Anti-freeze lubrication / heating |

| Corrosive / Wet | Stainless steel or anodized aluminum |

| Dusty | Filters and dust covers |

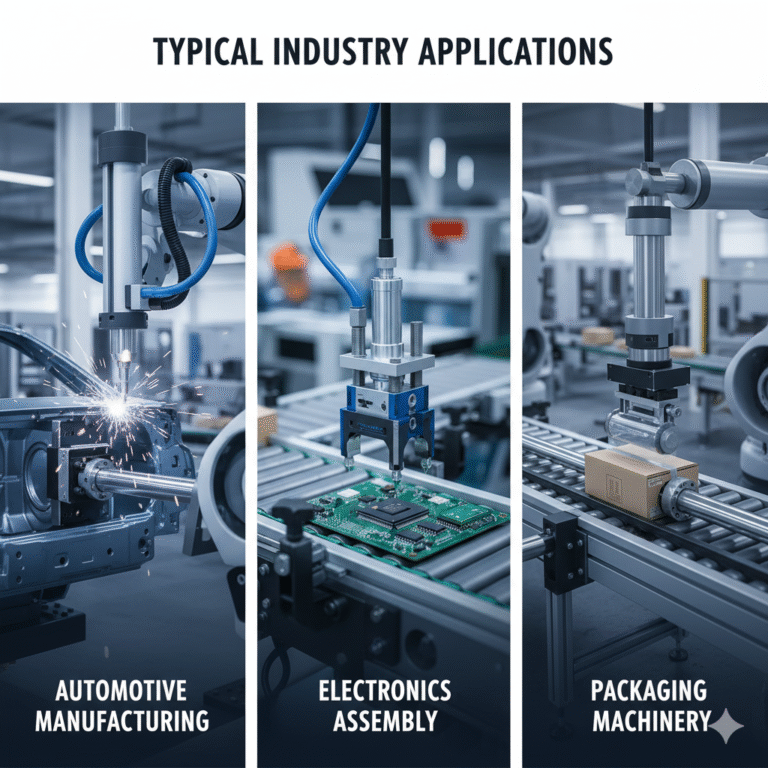

5. Typical Industry Applications

| Industry | Scenario | Recommended Cylinder |

|---|---|---|

| Automotive Manufacturing | Welding, stamping, handling | Large-bore cushioned cylinders |

| Electronics Assembly | Pick-and-place, testing | Miniature or anti-rotation cylinders |

| Packaging Machinery | Pushing, sealing, cutting | Rodless or compact cylinders |

| Food & Pharma | Filling & packaging in clean environments | Stainless steel cylinders |

| Warehousing & Logistics | Sorting and routing | Guided cylinders or rotary cylinders |

| Robotics | Gripping and flipping | Rotary or angular cylinders |

6. Common Mistakes and Practical Tips

Frequent Mistakes

Selecting cylinders based only on bore size

Excessive stroke causing rod bending or barrel vibration

Uneven mounting surfaces damaging seals

Air with moisture/oil causing sticking and leakage

Ignoring energy efficiency

Recommended Engineering Practices

Prefer ISO-standard cylinder models

Use cushioning for high-speed and long-stroke applications

Apply sensors + proportional control for precision operations

Establish regular lubrication and filtration maintenance