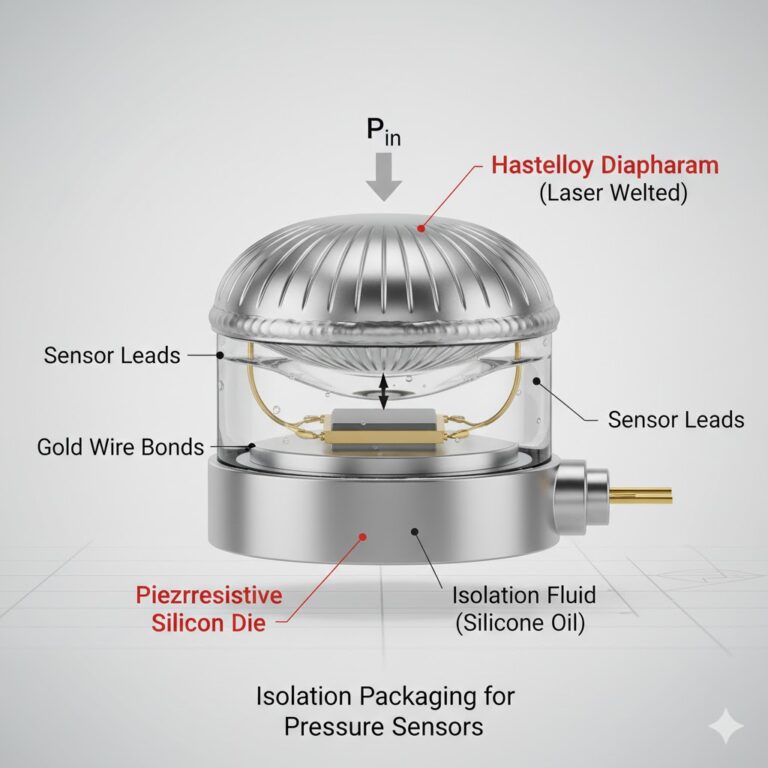

Pressure sensors use pressure-sensitive chips (such as piezoresistive silicon membranes) to detect pressure changes. If the sensor comes into direct contact with corrosive media, the silicon membrane may be damaged, affecting performance and reducing the sensor’s lifespan. Therefore, protective packaging is required to safeguard the pressure-sensitive chip while still allowing the pressure to be transmitted to the diaphragm.

Piezoresistive Pressure Sensors

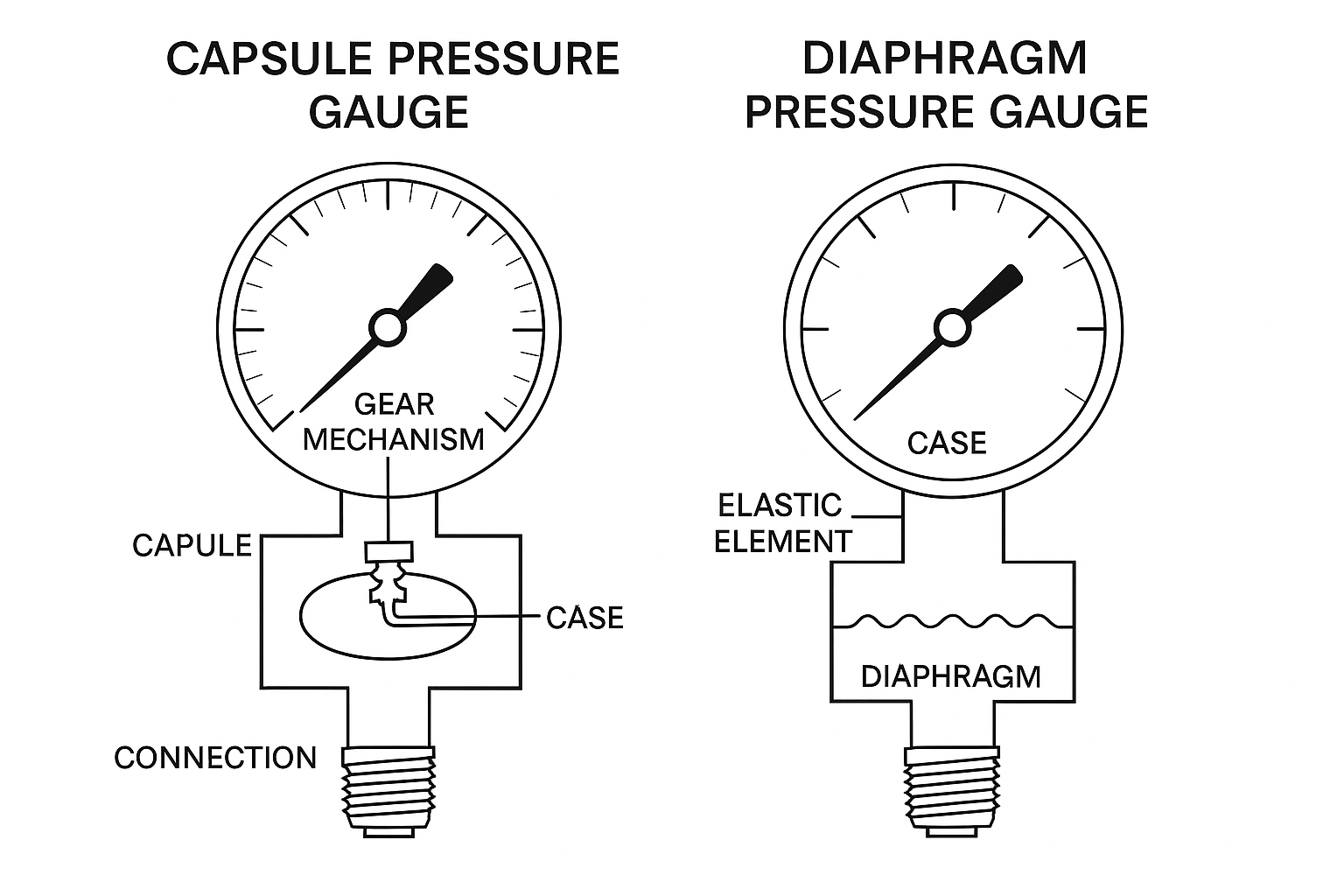

A common method for protecting the pressure-sensitive chip is to encapsulate it within a sealed chamber filled with a certain type of fluid, which is known as an isolation-type packaging. An external stainless steel or Hastelloy diaphragm is welded to the chamber, and the diaphragm’s thickness is determined by the pressure range to be measured. The diaphragm deforms elastically when pressure is applied, causing a change in the volume of the sealed chamber. This change is transmitted as pressure to the pressure-sensitive chip.

Isolation Packaging Process

Fixing the Pressure-Sensitive Chip: The pressure-sensitive chip is secured inside the chamber that will be sealed.

Connecting the Chip to the Leads: Gold wire is used to connect the chip to the sensor leads.

Welding the Diaphragm: The stainless steel corrugated diaphragm is welded to the sealed sensor chamber using laser welding technology.

Filling the Chamber with Oil: The chamber is filled with purified silicon oil, and the leads are sealed to form a complete isolated metal package structure.

Types of Oil Used in Pressure Sensors

The most commonly used oil in pressure sensors is dimethylsilicone oil (also known as polydimethylsiloxane), which is a colorless and transparent viscous liquid. Its operating temperature range is from -50°C to 180°C, and it can be used at temperatures up to 200°C in the absence of air or inert gases. Dimethylsilicone oil offers excellent chemical stability, making it suitable for most applications.

However, when measuring gases like oxygen or hydrogen, the leakage of dimethylsilicone oil can cause dangerous explosions. In such cases, fluorocarbon oil is typically used. Fluorocarbon oil, mainly composed of trifluorochloroethylene, has high thermal stability, non-polarity, chemical inertness, and is non-flammable. It is compatible with strong oxidizers like chlorine and oxygen within certain viscosity ranges, effectively preventing reactions with gases and minimizing explosion risks.

Conclusion

The need for oil in pressure sensors is critical to both protect the sensitive components and ensure the accurate transmission of pressure. By choosing the appropriate oil, such as dimethylsilicone or fluorocarbon oil, manufacturers can ensure long-term reliability and performance of pressure sensors in various industrial applications.