In industrial settings, digital communication protocols like RS232, RS485, and CAN are commonly used for transmitting digital signals. However, when it comes to transmitting analog signals—such as those from sensors measuring temperature, pressure, speed, or angle—a different approach is needed. The most widely adopted method in industry is the use of a 4-20mA current loop for analog signal transmission.

This article will explore why the 4-20mA current loop is the preferred method for transmitting analog signals in industrial environments, covering its advantages, working principles, and practical applications.

1. What is the 4-20mA Current Loop?

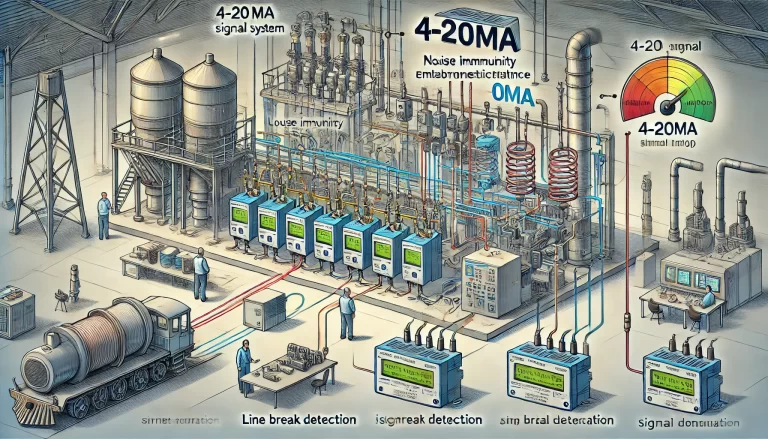

The 4-20mA current loop is an analog signal transmission standard widely used in industrial process control systems. It is defined by the International Electrotechnical Commission (IEC) and has been adopted globally, including in China. In this system:

4mA represents the minimum signal value (e.g., 0% of the measured parameter).

20mA represents the maximum signal value (e.g., 100% of the measured parameter).

The signal is transmitted as a current, which is less susceptible to noise and voltage drops over long distances compared to voltage signals. At the receiving end, the current is typically converted into a voltage signal (e.g., 1-5V) using a precision resistor (usually 250 ohms).

2. Why Use Current Signals Instead of Voltage Signals?

2.1 Noise Immunity

One of the primary reasons for using current signals is their immunity to noise and interference. In industrial environments, electrical noise can reach several volts, but the power of this noise is typically very low, resulting in noise currents in the nanoampere (nA) range. Since the 4-20mA signal operates at much higher current levels, the noise has a negligible effect on the signal integrity.

2.2 Long-Distance Transmission

Current signals are also ideal for long-distance transmission. The high internal impedance of the current source ensures that the signal remains accurate even over long distances. Voltage signals, on the other hand, are affected by the resistance of the transmission wires, leading to voltage drops and signal degradation.

2.3 Simple Conversion to Voltage

At the receiving end, a 250-ohm resistor is often used to convert the 4-20mA current signal into a 1-5V voltage signal, which can be easily processed by control systems. The low input impedance of the receiver ensures that even nA-level noise currents produce only minimal voltage noise.

3. Why 4mA and 20mA?

3.1 The 4mA Lower Limit

The 4mA lower limit serves two purposes:

It provides a “live zero” reference, meaning that a 4mA signal represents the minimum value (e.g., 0% of the measured parameter). This allows for the detection of wire breaks or sensor failures: if the current drops below 4mA (typically to 0mA), it indicates a fault condition.

The 4mA baseline also provides enough power to operate the sensor or transmitter itself, especially in two-wire systems where the same wires are used for both power and signal transmission.

3.2 The 20mA Upper Limit

The 20mA upper limit is chosen for safety reasons. In hazardous environments, such as those with explosive gases, the energy from a 20mA current interruption is too low to ignite the gas. This makes the 4-20mA signal suitable for use in intrinsically safe applications.

4. Two-Wire, Three-Wire, and Four-Wire Systems

4.1 Two-Wire Systems

In a two-wire system, the same pair of wires is used for both powering the transmitter and transmitting the 4-20mA signal. This is the most common and cost-effective setup, as it minimizes wiring complexity. The transmitter operates on the 4mA baseline current, and the signal varies between 4mA and 20mA based on the measured parameter.

4.2 Three-Wire Systems

In a three-wire system, the transmitter has separate wires for power and signal, but the ground (GND) is shared between them. This setup is less common but can be useful in certain applications where additional power is required.

4.3 Four-Wire Systems

In a four-wire system, the transmitter has completely separate wires for power and signal. This is typically used in more complex systems where isolation between power and signal is required.

5. Advantages of the 4-20mA Signal Standard

5.1 Noise Immunity

As mentioned earlier, current signals are less susceptible to electrical noise, making them ideal for industrial environments.

5.2 Long-Distance Transmission

The high impedance of the current source ensures that the signal remains accurate even over long distances.

5.3 Live Zero Detection

The 4mA baseline allows for easy detection of wire breaks or sensor failures.

5.4 Intrinsic Safety

The 20mA limit ensures that the signal is safe for use in hazardous environments.

5.5 Compatibility

The 4-20mA standard is widely adopted, making it easy to integrate with a variety of sensors, transmitters, and control systems.

6. How Does the 4-20mA Current Loop Work?

In a typical 4-20mA current loop, the sensor or transmitter modulates the current in the loop based on the measured parameter. For example, a temperature sensor might output 4mA at 0°C and 20mA at 100°C. The current is then transmitted over twisted-pair wires to a receiver, which converts the current into a voltage signal using a precision resistor (usually 250 ohms). This voltage signal can then be processed by a control system or displayed on a monitor.

7. Why Not Use Voltage Signals?

While voltage signals (e.g., 0-5V or 0-10V) are simpler to generate and measure, they are more susceptible to noise and voltage drops over long distances. In contrast, current signals are unaffected by wire resistance and are more robust in noisy environments.

8. Other Signal Standards

While 4-20mA is the most common standard for analog signal transmission, other signal types are also used in specific applications:

0-5V and 0-10V: These voltage signals are simpler but are generally limited to shorter distances due to noise and voltage drop issues.

3.33mV/V and 2mV/V: These are typically used in strain gauge and load cell applications, where the output is proportional to the excitation voltage.

9. Conclusion

The 4-20mA current loop is the industry standard for analog signal transmission due to its noise immunity, long-distance capability, and intrinsic safety. Its ability to provide both power and signal over the same wires (in two-wire systems) makes it a cost-effective and reliable solution for industrial applications. While other signal standards exist, the 4-20mA standard remains the most widely used for its robustness and versatility.