1. Understanding Level Transmitter Migration

Range migration refers to the adjustment of a level transmitter’s measurement range so that it accurately reflects the actual liquid level. In certain installations—such as when the transmitter is not mounted at the zero-level reference, or when special process media or sealing fluids are involved—the raw pressure readings may deviate from the true level. Migration compensates for these offsets.

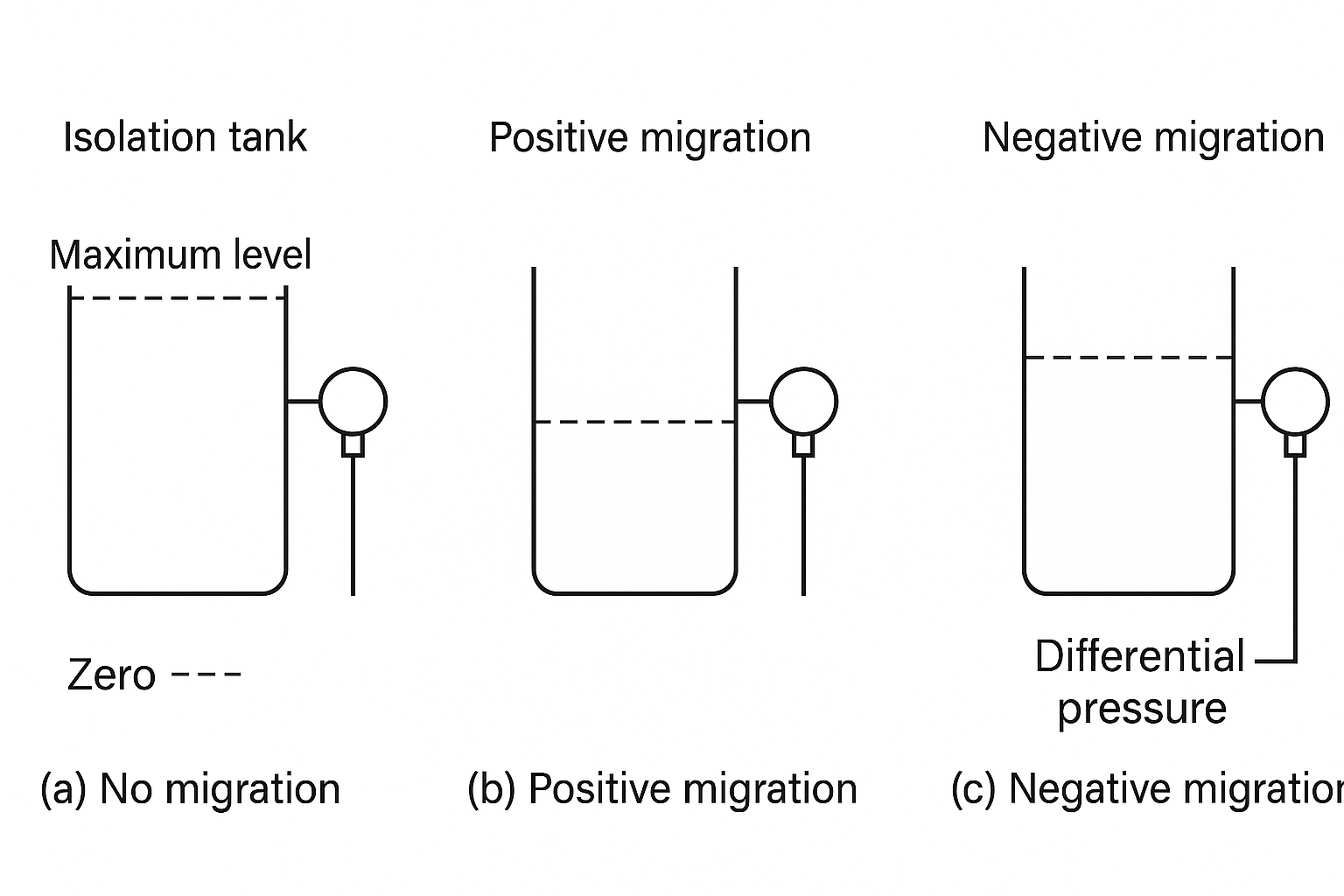

There are three common migration types:

(a) No Migration

The measurement starts from zero. This is the standard condition.(b) Positive Migration

The transmitter reads a pressure above zero even when the liquid level is at its minimum.(c) Negative Migration

The transmitter reads a negative pressure (below atmospheric or reference) when the liquid level is at its minimum.

The amount of migration is typically expressed in pressure units (e.g., mmH₂O, kPa) or as a percentage of the measurement span.

2. Difference Between Zero Adjustment and Migration

Zero Adjustment: When the differential pressure (ΔP) is zero, the transmitter output is forced to 4 mA (0%).

Migration: When ΔP ≠ 0 at minimum liquid level, but the transmitter is still required to output 4 mA (0%).

Example:

Let’s define:

y_min: Lower limit of transmitter output (e.g., 4 mA)x_min: Minimum of actual measurement rangeIf

x_min = 0, it’s zero adjustmentIf

x_min ≠ 0, it’s migration

Further classification:

Positive migration: The zero point is shifted above the reference point

Negative migration: The zero point is shifted below the reference point

3. When Is Migration Required?

Migration is often required in the following typical field scenarios:

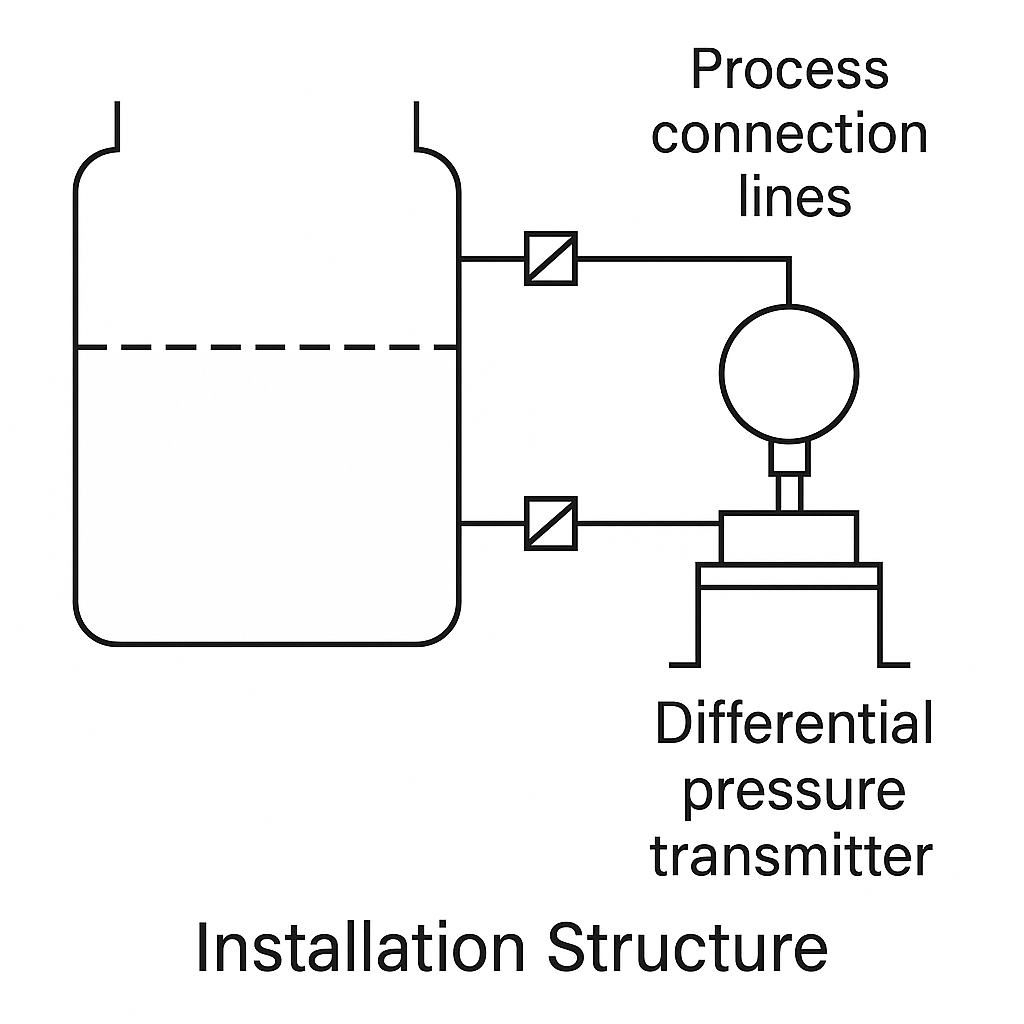

(1) Differential Pressure Transmitters with Dual Flanges

Application: Sealed tanks containing corrosive, viscous, or crystallizing media (e.g., reactors in chemical plants).

Reason for Migration: The upper and lower flanges are installed at different heights, causing an inherent pressure offset.

(2) Single-Flange Transmitters with Capillary Tubes

Application: Open tanks or closed vessels

Reason for Migration: The mounting position is above or below the minimum liquid level, leading to pressure discrepancies due to the elevation difference.

(3) DP Transmitters with Remote Sealed Chambers

Application: Media with high viscosity or strong corrosion (e.g., sulfuric acid, heavy oil)

Reason for Migration: The isolation fluid forms a static liquid column that adds pressure to the transmitter, requiring compensation.

4. Field Experience & Tips

(1) Quick Calibration for Dual-Flange Transmitters

Close one isolation valve to equalize both flanges to atmospheric pressure.

The transmitter’s PV (process variable) reading at this point is the migration value (lower range).

Calculate the full span from the actual tank height and set the upper range accordingly.

(2) Core Principle of Migration

Migration ensures the transmitter’s 4–20 mA output corresponds correctly with actual level.

If the transmitter outputs 4 mA when the tank is empty → No migration.

If the output at empty is above 4 mA → Positive migration.

If the output is below 4 mA → Negative migration.

5. Summary

Level transmitter migration is a crucial calibration step in achieving accurate and reliable level measurements, especially in non-standard or harsh process conditions. Understanding the type and value of migration ensures that control systems receive precise feedback for safe and efficient operation.

📌 Note: Migration must be distinguished from zero adjustment and should always be considered during configuration of level transmitters with remote seals, capillaries, or unusual installation elevations.