Client Inquiry:

This is a very typical and often overlooked issue in engineering sites. In a temperature measurement system, the Temperature Well, though a small metal component, plays a critical role in the overall instrument system. It is responsible for protection, heat transfer, support, and safety isolation.

In other words, the Temperature Well not only determines whether the temperature probe can work stably in high temperature and high-pressure environments for extended periods but also directly affects the accuracy, response time, and reliability of the temperature measurement signal. In industries like chemicals, energy, metallurgy, and pharmaceuticals, it serves as the key interface between the temperature sensor and the process medium.

Understanding the function of a Temperature Well can not only improve temperature measurement accuracy but also help avoid many potential safety risks.

I. What is a Temperature Well?

A Temperature Well is a metal casing used to protect temperature sensors. It isolates thermocouples or RTDs (Resistance Temperature Detectors) from the process medium, allowing the sensor to operate safely in environments with high temperature, pressure, strong corrosion, or high fluid velocity.

The Temperature Well acts as a “protective chamber” for the temperature probe and as a “heat transfer channel” for the process temperature signal. In high-pressure reaction systems or steam pipelines, it also allows for in-service sensor replacement without needing to shut down or depressurize the system, improving maintenance efficiency.

II. Four Main Functions of a Temperature Well

Protection:

Resists chemical corrosion, high-speed fluid abrasion, and mechanical vibrations.

Heat Transfer:

Transfers the medium’s temperature to the sensing element via the metal wall.

Mechanical Support:

Ensures the stability of the probe under high flow conditions, preventing breakage.

Maintenance and Replacement:

Allows sensor replacement while the system is pressurized.

For any continuous, long-running process systems (such as polymerization reactors and steam pipelines), the presence of a Temperature Well is crucial for both maintenance and safety.

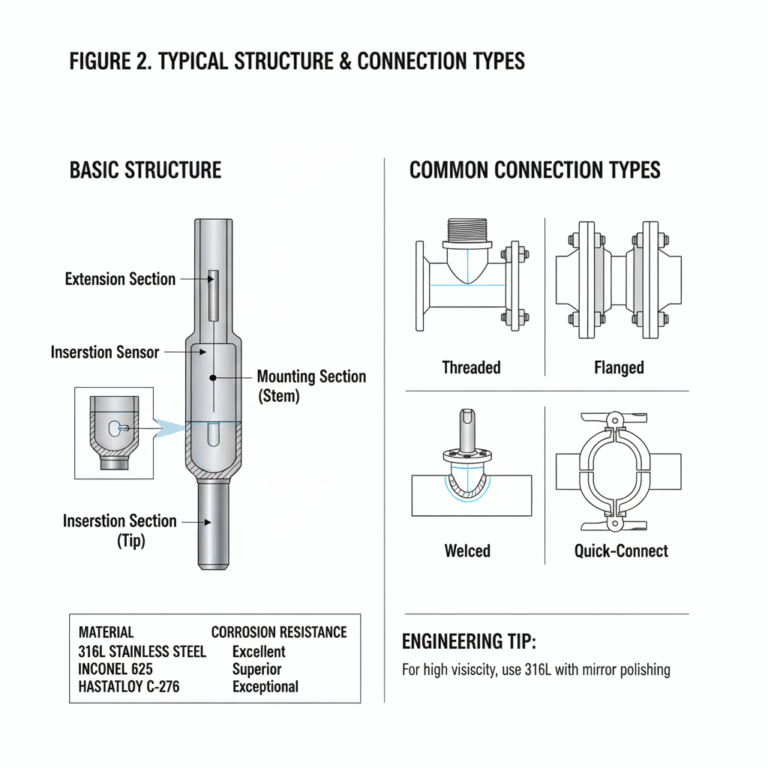

III. Typical Structure and Materials of a Temperature Well

Basic Structure:

A typical Temperature Well consists of three parts:Insertion Section (Tip): Directly contacts the medium for heat transfer.

Mounting Section (Stem): Used for fixing and sealing, usually with threads or flanged connections.

Extension Section: Connects the instrument or protective casing.

Common Connection Types:

| Type | Features | Application Scenarios |

|---|---|---|

| Threaded | Simple structure, easy to install | Low-pressure pipelines, storage tanks |

| Flanged | Strong pressure resistance, reliable seal | High-pressure vessels, main steam pipelines |

| Welded | High rigidity, permanent installation | High-temperature or high-vibration conditions |

| Quick-connect | Allows rapid sensor replacement | Pharmaceutical and food industries |

Material Selection Guidelines:

Materials should meet the following requirements: good heat transfer, corrosion resistance, and fatigue resistance.According to ASME PTC 19.3 TW-2016 and GB/T 18404 standards, common material choices include:

| Material | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|

| 304 Stainless Steel | Good | Moderate | Clean gases, water systems |

| 316L Stainless Steel | Better | Excellent | Chloride ion solutions, organic acid systems |

| Inconel 600/625 | Moderate | Excellent | High-temperature steam, ammonia decomposition gas |

| Titanium | Moderate | Excellent | Strong oxidizing environments |

| Hastelloy C-276 | Moderate | Excellent | Strong acidic media (e.g., HCl, H₂SO₄) |

Engineering Tips:

If the process medium has high viscosity or is prone to scaling, it is recommended to use 316L with mirror polishing to reduce thermal resistance due to fouling.

For temperatures above 500°C with high flow velocity, Inconel material is recommended.

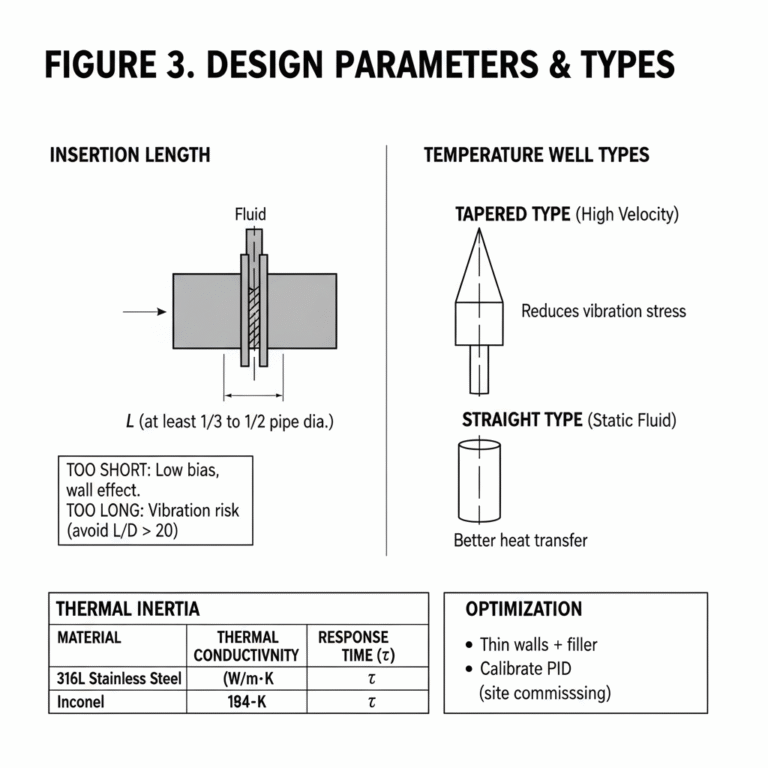

IV. Design Parameters and Key Calculations

Insertion Length:

The effective insertion depth of a Temperature Well determines the representativeness of the measurement and mechanical strength.Too short a length: Measurement will be biased low (close to the wall).

Too long a length: Increased risk of vibration.

ASME PTC 19.3 TW standards recommend that the insertion length should be at least 1/3 to 1/2 of the pipe diameter, and its natural frequency should be greater than 2.2 times the fluid’s vortex shedding frequency.

Practical Tips:

For high-speed fluids (velocity > 2 m/s), tapered Temperature Wells (Tapered Type) should be used to reduce vibration stress.

For static liquid media, straight-wall Temperature Wells (Straight Type) can improve heat transfer performance.

Avoid designs with a “Length-to-Diameter (L/D) ratio > 20.”

Temperature Response and Thermal Inertia:

The thermal conductivity and thickness of the Temperature Well wall directly impact the temperature response speed. In automatic control systems (like PID control for reactors), the thermal inertia of the Temperature Well is often the source of control delays.

| Material | Thermal Conductivity (W/m·K) | Typical Response Time (τ) |

|---|---|---|

| Copper | 390 | < 1 s |

| Carbon Steel | 45 | 1-2 s |

| 316L Stainless Steel | 16 | 2-6 s |

| Inconel 600 | 11 | 5-8 s |

Optimization Suggestions:

For systems with high temperature control requirements, use thin-walled Temperature Wells with high thermal conductivity fillers (e.g., alumina powder).

During site commissioning, first calibrate the thermal inertia parameters, then adjust the PID coefficients.

V. Safety and Maintenance

The rupture or leakage of a Temperature Well is a high-risk event.

Typical Incident Case:

In 2004, at Monroe Power Plant in the U.S., a Temperature Well ruptured due to resonance, which was sucked into the turbine, causing millions of dollars in damage.

Recommended Maintenance Cycle:

| Inspection Item | Frequency | Method |

|---|---|---|

| Wall thickness and weld inspection | Annually | Ultrasonic Testing (UT) |

| Corrosion rate assessment | Every six months | Sampling analysis or thickness measurement |

| Temperature drift verification | Quarterly | Comparison with reference temperature points |

| Vibration monitoring | Continuous | Acceleration sensor monitoring |

If significant response delays or abnormal temperature fluctuations occur, inspect the Temperature Well for deformation or scaling.

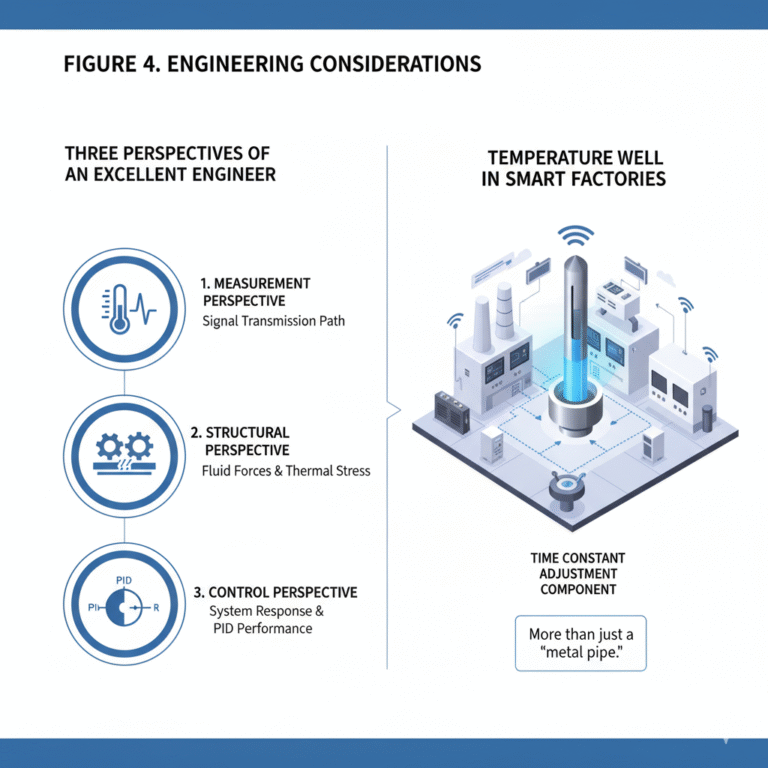

VI. Engineering Considerations

Although the Temperature Well is just a component, it directly influences the accuracy of temperature measurement, the safety of the system, and control quality.

An excellent engineer should understand the Temperature Well from three perspectives:

Measurement Perspective: It is part of the signal transmission path.

Structural Perspective: It bears fluid forces and thermal stress.

Control Perspective: It affects system response time and PID performance.

In smart factories, the Temperature Well is not just a “metal pipe” but a time constant adjustment component of the measurement system.

VII. Conclusion

The design of the Temperature Well is an “invisible technical threshold” in the temperature measurement system. Only by understanding its thermal conductivity, mechanical properties, and process background can one design a truly reliable temperature measurement system.

In engineering sites, the Temperature Well is crucial not only for measurement but also for control accuracy, safety boundaries, and system stability.