INTRODUCTION

Flowmeters are divided into two categories: liquid and gas. Because of the differences in characteristics between liquids and gases, liquids are typically measured in terms of volumetric flow rate, whereas gases are measured in terms of mass flow rate. While some volumetric systems can monitor gas flow rates, totalized flow can cause issues. When measuring air or other gases, mass-flow sensing technology is usually the best option, especially in crucial applications.

The measurement of air and other gases in chemical process industries (CPI) manufacturing plants is critical for a variety of reasons, including safety, process control, product quality, production efficiency, environmental compliance, and cost. Serious accidents, emergency shutdowns, unplanned maintenance, production slowdowns, and cost overruns are all possible outcomes when measuring air or other gases is inaccurate or unreliable.

Only roughly half of the possible flow measurement methods for gases now available are suited for the heavy-duty metering applications seen in the most difficult CPI operations. Depending on what material needs to be measured, the desired accuracy, where it needs to be measured, and so on, each technology has its own set of advantages and disadvantages.

When it comes to choosing a flowmeter for gas measurement jobs in CPI plants, the expression “information is power” becomes a key consideration. The same flow-sensing technology that is chosen for one application in a plant may be the wrong choice for another application, even though they are close by.

In big CPI plants, the cost of picking the wrong flowmeter — in terms of extra maintenance, repairs, and spares — can easily reach tens of thousands of dollars. The cost of failing to perceive the small differences in air and other gas flow measurement systems can be punished if safety incidents, poor product quality, a production delay, or environmental compliance difficulties occur.

COMMON MEASUREMENT APPLICATIONS

Flowmeters are used to determine the rate of flow of air or other gases, as well as the total flow. Because of the potentially hazardous operating environments found in CPI plants, gas flowmeters typically require hazardous area approvals (for example, HazEx) and are frequently required to comply with the IEC 61508/61511 (SIL) standard as part of a Safety Instrumented System (SIS) in many applications. The following sections cover four of the most typical and difficult gas flow-measurement applications in chemical facilities.

GAS DISTRIBUTION METERING

For inert ions, purging, or blanketing, many chemical processes necessitate huge changing volumes of particular gases such nitrogen, argon, and oxygen. Other particular gases, such as hydrogen, may be required as a catalyst (Figure 1). For process control, gas inventory control, and cost management, reliable measurements of these gases are required.

FLARING SYSTEMS

Many chemical processes require massive shifting volumes of certain gases such as nitrogen, argon, and oxygen for inert ions, purging, or blanketing. As a catalyst, other gases, such as hydrogen, would be needed (Figure 1). The accurate measurement of these gases is necessary for process control, gas inventory control, and cost management.

TANK BLANKETING

Many chemical processes require massive shifting volumes of certain gases such as nitrogen, argon, and oxygen for inert ions, purging, or blanketing. As a catalyst, other gases, such as hydrogen, would be needed (Figure 1). The accurate measurement of these gases is necessary for process control, gas inventory control, and cost management.

STACK GAS MONITORING

Multiple flow sensors must be positioned in strategic areas to measure the discharge of plant waste gases through huge stacks with scrubber systems (Figure 4). Environmental compliance is dependent on these stack-gas systems. EPA 10 CFR 40 and 40 CFR 98; E.U. Directives 2003/87/EC and 2007/589/EC; US MMR 30 CFR Part 250, Subpart K, Section 250; and others are among the standards that must be met by Stack Continuous Emission Monitoring Systems (CEMS).

GAS FLOW CHALLENGES

Process and instrument engineers face hurdles when working on applications that require precise, dependable gas-flow measurement. The sections that follow go over various aspects that must be taken into account when selecting a flow measuring or sensing technology.

LOW AND HIGH FLOWS

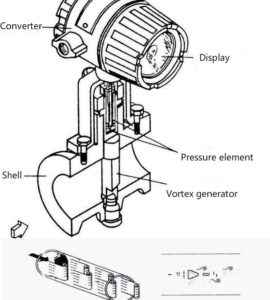

To discover and monitor leaky valves and the regular low-flow operation associated with day-to-day operations, sensitivity to low-flow circumstances is necessary. During system upsets, the capacity to measure very high flows is required, necessitating the use of a vortex meter that can correctly measure flow throughout a very wide turndown range.

METER CALIBRATION

Vortex flowmeters must be calibrated especially for hydrocarbon composition gases and to correspond to actual process conditions.

LARGE LINE SIZES

The number of functional and acceptable flowmeter sensing technology diminishes as pipe widths increase. When it comes to selecting a flowmeter for longer lines, specific considerations are required.

AVAILABLE STRAIGHT RUN

In order to accomplish reliable flow measurement, all velocity-based flowmeter systems necessitate some straight-run pipe both upstream and downstream of the meter. In crowded production and processing operations, these straight-run standards may be impossible to meet.

LIMITED ACCESS

It is frequently difficult to get and regain access to pipelines for installation, maintenance, or servicing. Spool-piece flowmeters, for example, can necessitate lengthy process shutdowns and high onsite personnel costs to install and maintain, as compared to insertion-style meters, which can be quickly inserted into or retracted out of the process using a ball valve.