INTRODUCTION

Before we get into the verification of a vortex flowmeter, we need to understand what saturated steam is all about, and to that end, we will answer the question;

WHAT IS SATURATED STEAM?

Saturated steam also commonly referred to as dry steam occurs when the liquid and gaseous stages of water transpire concurrently at a specific pressure and temperature. The point where the production rate of steam equals the vapourization rate of boiling is known as saturated steam.

When water is heated, the temperature of the water body rises till it gets to the boiling point (temperature) for the prevailing pressure. Any further increase in heating of the water will only lead to vapor formation without any rise in the temperature of the water body, this is due to the extra heating energy supplied being immediately used as latent heat of vaporization. Although the saturated steam can not be seen by our eyes, it exists as this is because it is free from water droplets. Saturated steam occurs at around 100 degrees Celcius (212 F) at normal atmospheric pressure.

With this brief explanation, we now have to answer the question;

WHY DO TEXTILE PLANTS NEED SATURATED STEAM?

In modern production processes, saturated steam is required as an integral part of the production process, the best examples of industries that regularly require saturated steam include (but are not limited to) chemical, textile, wood, and paper industries.

In the textile industries (which is our focus industry) saturated steams are needed as they are superheated at prevailing pressures and then transported to driers where it is used to dry the designs and ink printed on fabric.

Often within internal plant networks, only saturated steam with very high boiler pressures are available, a controller steam ejector with a water cooling injection which is known as a saturated steam generator or desuperheater will help to transport the heated water to the driers. This simultaneously reduces the steam pressure and injects the condensate directly into the superheated steam for cooling.

THE VORTEX FLOWMETER.

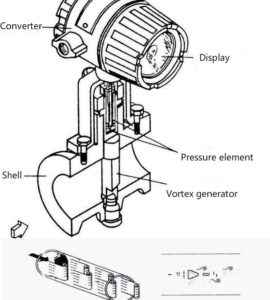

A vortex flowmeter is appropriate for flow measurements including moving parts. They come in industrial-grade metal and/or plastic construction, have low sensitivity to changes in process conditions, and have no moving parts, resulting in a lower rate of wear and tear than other types of flowmeters.

The vortex shedding principle governs the operation of a vortex flowmeter, which defines how oscillating vortexes occur as fluid flows past a bluff body. The frequency with which vortexes are shed is influenced by the size and shape of the body. It’s suitable for applications that require little upkeep. Industrial vortex meters are made to order and must be sized for specific applications.

ACCURACY AND RANGEABILITY

As viscosity increases, the Reynolds number decreases, causing the vortex rangeability to decrease. As a function of allowable accuracy and rangeability, the maximum viscosity limit is between 8 and 30 centipoises. If the vortex meter has been suitably scaled for the application, rangeability should be greater than 20:1 for gas and steam applications and greater than 10.1 for low viscosity liquid applications.

The metering error increases as the Reynolds number decreases, leaving the inaccuracy expected of most vortex meters at 0.5 percent of the rate of Reynolds numbers greater than 30,000. The inaccuracy can reach 10% of the real flow at Reynold’s numbers fewer than 10,000.

APPLICATIONS AND LIMITATIONS

Often within internal plant networks, only saturated steam with very high boiler pressures are available, a controller steam ejector with a water cooling injection which is known as a saturated steam generator or desuperheater will help to transport the heated water to the driers. This simultaneously reduces the steam pressure and injects the condensate directly into the superheated steam for cooling

For the meter’s K factor to change over time, the fluid must have the tendency to coat or build upon the bluff body, as is the case with sludge and slurry services, therefore vortex-shedding flowmeters are not recommended for such applications. In a 2-year test on limestone slurry, it was discovered that dirty fluid which has only moderate amounts of non-coating solids, can be accepted for this service. As at the end of the test, the K factor was found to have changed only by 0.3% from the original factory calibration, although the bluff body tube was badly scarred and pitted.