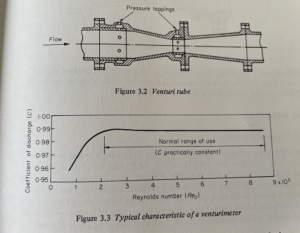

The venturi tube, often known as the venturi meter, is the original form of differential pressure meter. (Strictly speaking, the “venturi tube” is the primary device and the name “venturi meter” refers to the combination of primary and secondary-but many users do not speak strictly!) A typical design is shown in Figure 3.2. Because energy losses are low and the flow conditions are not far removed from the ideal, the discharge coefficients of venturi meters are generally Reynolds number, especially at low values of ReD.

A characteristic curve obtained from calibrating a typical venturi tube is given in Figure 3.3. The coefficient falls off sharply at low Reynolds numbers. and venturi tubes are normally used only within the range where C is practically constant.

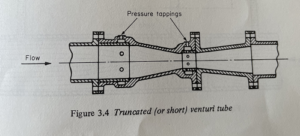

Various ways of modifying the venturi tube so as to make it more compact without greatly impairing its performance are in use. In the truncated venturi tube (Figure 3.4) the downstream cone is shortened, while in the venturi nozzle (Figure 3.5) the contraction is shortened as well.

Application

Venturi tubes are divided into built-in venturi tubes and inserted venturi tubes according to their structures. It has achieved good results in the measurement of combustion air, cold air and gas (blast furnace gas, coke oven gas, converter gas) in hot blast stoves in steel plants and in the measurement of large diameter and low flow rate pipes for boiler primary air and secondary air in thermal power plants. Solve the problem of accurate measurement of various gas flows in current industrial enterprises with low pressure, large diameter and low flow rate. Fluid measuring device with wide measuring range and easy installation.

The unique structural design and data processing methods are based on strict fluid mechanics, and are calibrated for real flow in a large national key wind tunnel laboratory.

It can be widely used in the control and measurement of large-diameter fluids in petroleum, chemical, metallurgy, electric power and other industries.

Characteristic

(1) The resistance to the fluid is small, about 150Pa, so the energy consumption is low.

(2) Large pressure difference, high precision and wide measuring range.

(3) Good stability and smooth pressure difference characteristics.

(4) It can be used in a wide range of general gases, flue gases, blast furnace gases containing many impurities, etc., and will not cause clogging during long-term use.

(5) Easy installation and long-term maintenance.

(6) The front and rear straight pipe sections are shorter than the standard throttling device, about 1.5D in front and 1D in back.

(7) It has an integrated structure of online temperature and pressure self-correction.