An orifice plate is simply a plate with a hole in it, forming a partial obstruction to the flow. As will be seen from Figure 3.6, the flowing fluid follows the same kind of path as it does in the venturi tube. However, the narrowest part of the flow stream is not in the orifice itself, but some distance downstream; this narrowest section is known as the vena contracta. Between the vena contracta and pipe wall, numerous eddies form. These dissipate a great deal of kinetic energy in the form of heat and are responsible for the high head loss of this type of meter.

Because the diameter of the vena contracta cannot be measured, orifice plate calculations are always based on the diameter of the orifice. This practice leads to very low values of C for orifice plates, in the region of 0.6.

Concentric orifice plates

Most orifice plates are made with a circular orifice concentric pipe. Even so, there is considerable scope for variation in the geometry of orifice-plate meters, and especially in the positioning of the pressure tappings, and in the shape of the upstream edge of the orifice.

In the typical orifice-plate installation of Figure 3.7, the tapping is in the adjacent pipes at distances of one pipe diameter D upstream and D/2 downstream. Another common arrangement is to put the tapping in the pipe flanges tappings; if drilled obliquely so as to enter the pipe right by the orifice plate, they are termed corner tapping. The position of the tapping affects the discharge coefficient and account is taken of this in the predicted values of C given in the standards.

The orifice plate of Figure 3.7 is described as “square-edged” because that is the shape of its upstream face, although the less significant downstream edge is chamfered. This is much the commonest form for orifice plates, being almost universally used with clean gases and clean liquids of low viscosity. With viscous square and the upstream edge either radiused or chambered; the former is termed the quarter-circle orifice plate, and the latter the conical-entry orifice plate. These have a fairly constant value of C at Reynolds numbers between about 5000 to 50000.

The discharge coefficients of orifice plates are liable to vary with Reynolds number rather more than those of venturi tubes, but, with a plate made and used in accordance with the standards, C should not vary by more than about ±0.5% over the normal working range.

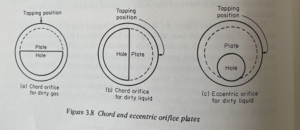

Eccentric and chord orifice plates

Concentric orifice plates cannot be used with dirty fluids because dirt would gradually build up behind the plate until its performance was seriously impaired. Instead, eccentric or chord orifice plates (Figure 3.8) are commonly used. These are, in general, rather less accurate than concentric orifice plates but, because there is a free path along the bottom of the pipe, solids cannot accumulate behind the plate to any serious extent. Annular orifice plates, which consist of a solid circular disc supported centrally in the pipe, have also been used for this purpose but are rarely employed nowadays.

Integral orifice plates

Some manufacturers offer a compact unit comprising an orifice plate with a differential pressure sensor and signal transmitter built-in. These assemblies are known as integral plates. They are normally available for the smaller pipe sizes only.

Orifice plates with bypass flowmeters

If instead of the usual differential pressure transducer, a small flow meter is connected across the pressure tapping of an orifice plate, the result is a metering system with special properties. These devices are dealt with in section 5.8.