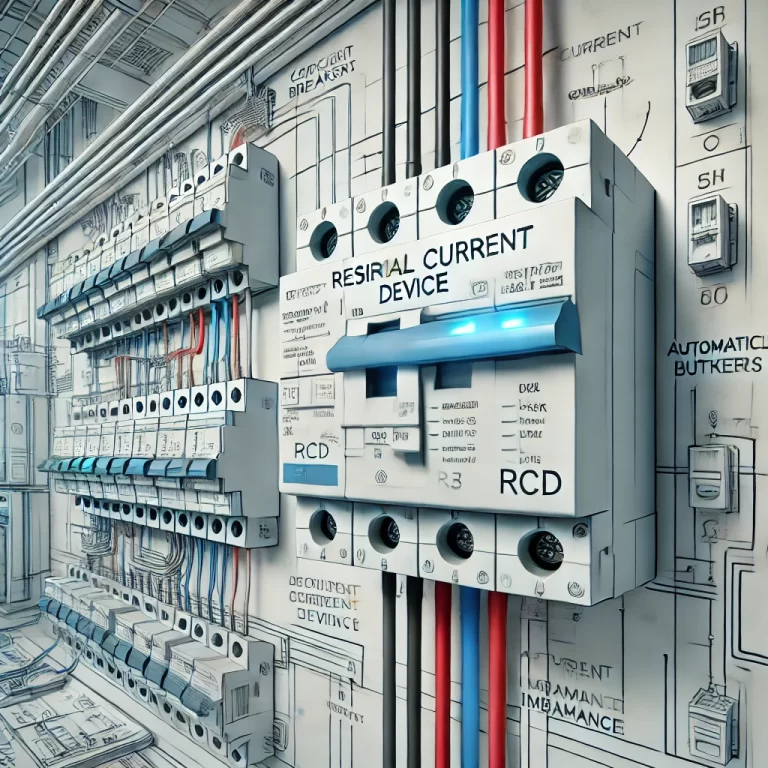

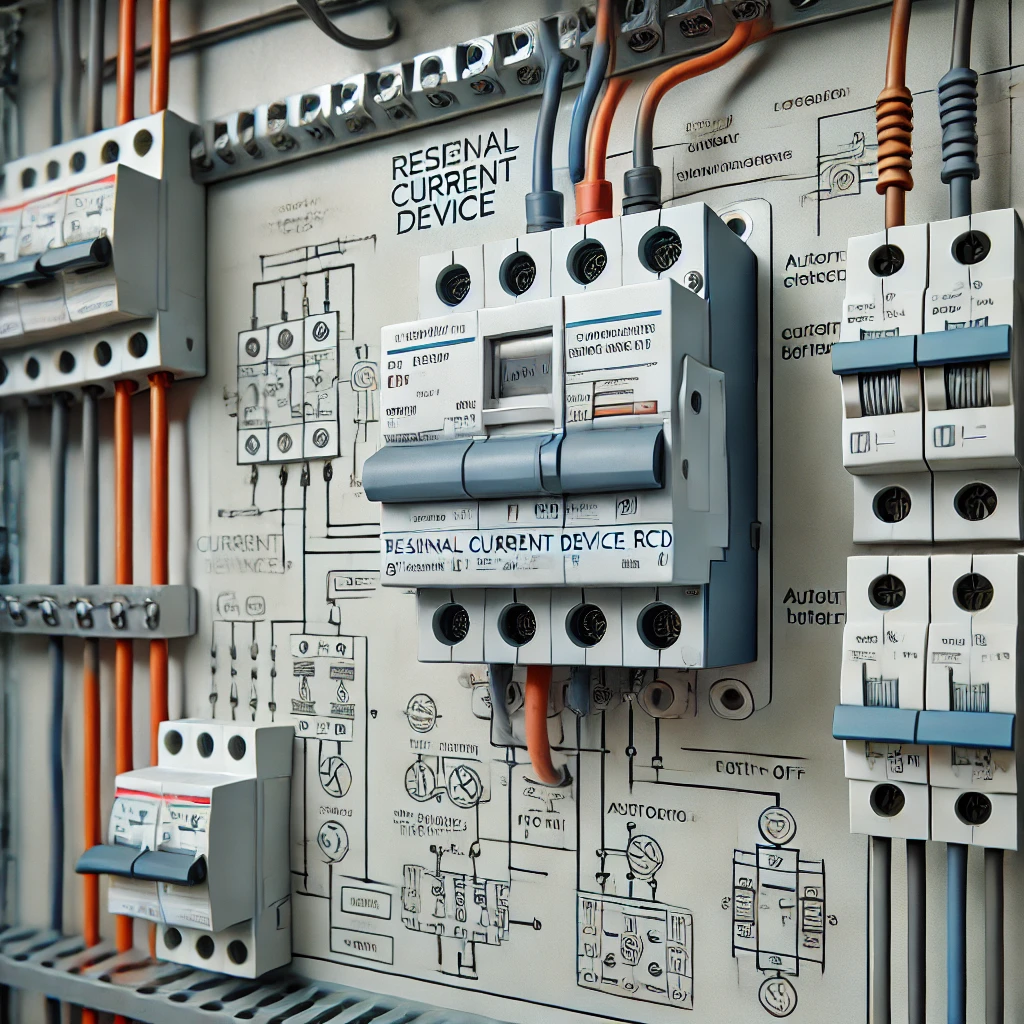

Residual Current Devices (RCDs), commonly referred to as leakage protection devices, are essential components of electrical safety. They belong to the family of circuit breakers, alongside air circuit breakers and isolating switches. In circuit diagrams, RCDs are often denoted by their acronym. Unlike air circuit breakers that provide short-circuit and overload protection, RCDs add a crucial feature: leakage trip protection.

Components and Functionality

An RCD typically comprises:

Detection Mechanism:

The orange component (as shown in diagrams) is responsible for testing the device. Users are advised to test the RCD monthly to ensure it functions correctly under leakage conditions.

Reset Button:

The blue button allows the device to be reset after tripping. Before reactivating the circuit, users must press this button to ensure the device is ready for operation.

How Does an RCD Work?

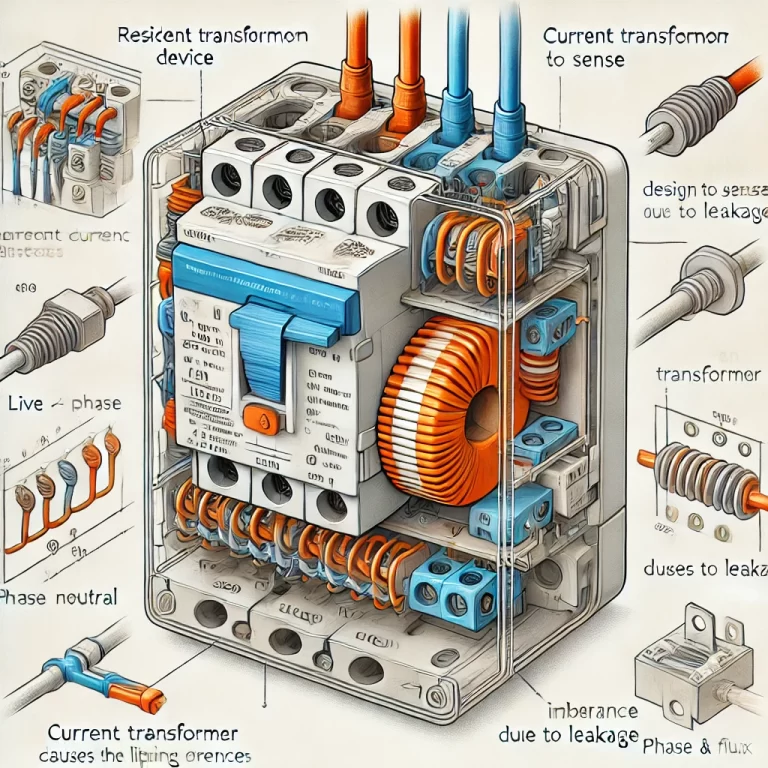

At the heart of an RCD lies a current transformer, a critical component designed to sense current differences. Under normal conditions, the electrical current flowing through the live (phase) wire and the neutral wire is equal in magnitude but opposite in direction. This balance ensures the magnetic flux induced in the transformer cancels out, and the RCD remains inactive.

However, when leakage or a ground fault occurs (e.g., through damaged insulation or accidental contact with live parts), the current balance is disrupted. This imbalance creates a net magnetic flux in the transformer, triggering the tripping mechanism. As a result, the RCD swiftly disconnects the power supply, preventing potential harm or fire.

Why Test the RCD?

Periodic testing is critical for ensuring the RCD’s reliability. By pressing the test button:

A small test current simulates a leakage condition.

The RCD should trip instantly, confirming its readiness to protect against actual leakage scenarios.

If the RCD fails to trip, it indicates a malfunction and should be inspected or replaced by a qualified technician.

Key Technical Specifications

RCDs come with varying sensitivity and current ratings to suit different applications:

Sensitivity: Measured in milliamps (mA), common ratings include 30mA for residential use, offering personal protection, and higher ratings for industrial settings.

Current Rating: Indicates the maximum current the RCD can handle without damage, typically ranging from 16A to 100A.

Practical Tips for Using RCDs

Installation:

Ensure that the RCD is installed by a certified electrician in compliance with local electrical codes.

Routine Maintenance:

Test the RCD monthly using the test button.

Inspect the wiring and connections periodically to prevent issues like loose contacts or insulation degradation.

Replacement Criteria:

Replace the RCD if it shows signs of wear, fails to trip during testing, or if the test button becomes unresponsive.

Conclusion

RCDs are vital for electrical safety, providing protection against electrical shocks and fires caused by ground faults. By understanding their principles, regularly testing them, and adhering to proper maintenance practices, users can ensure reliable protection for both residential and industrial environments. Proper installation and usage are key to maximizing their effectiveness and lifespan.