In the field of industrial communication, Modbus RTU and RS-485 are often mentioned together, leading many to mistakenly believe they are the same. In reality, these two concepts are fundamentally different—though they are tightly integrated in practical applications.

What is RS-485?

RS-485 is a physical layer communication standard, which defines how electrical signals are transmitted between devices. Like USB or Ethernet, RS-485 specifies voltage levels, signal timing, and wiring requirements, but it does not define how data is formatted or interpreted.

Key Features of RS-485:

Differential Signaling: Uses two wires (A and B) to transmit data, providing strong resistance to electrical noise—ideal for industrial environments.

Long Distance Capability: Supports communication distances up to 1200 meters with data rates typically ranging from 1200 bps to 115200 bps.

Multi-Drop Communication: Allows up to 32 devices to share the same bus, making it suitable for point-to-multipoint configurations.

Half-Duplex Transmission: Only one direction of communication is allowed at a time—either sending or receiving, not both simultaneously.

In short, RS-485 acts as the “transport channel”, managing the electrical transmission and hardware-level connectivity between devices.

What is Modbus RTU?

Modbus RTU is an application layer communication protocol, focused on how data is structured, encoded, and interpreted. Developed by Modicon in 1979, Modbus has become a widely adopted standard for device-to-device communication in industrial automation.

RTU (Remote Terminal Unit) mode is a compact and efficient binary transmission format, especially suited for systems with limited processing resources.

Key Features of Modbus RTU:

Frame-Based Data Transmission: Communication is organized into frames containing device address, function code, data, and a CRC (Cyclic Redundancy Check) for error detection.

Master-Slave Architecture: The master initiates communication, polling each slave device to execute commands. Slaves respond only when addressed.

Binary Efficiency: Data is transmitted in a binary format, making it faster and more compact than ASCII-based protocols.

It’s important to note that Modbus RTU does not specify how data is transmitted physically. For that purpose, RS-485 is often used as the underlying physical layer.

How Modbus RTU and RS-485 Work Together

As shown above, RS-485 and Modbus RTU operate at completely different levels:

| Layer | Component | Role |

|---|---|---|

| Physical Layer | RS-485 | Transmits electrical signals |

| Application Layer | Modbus RTU | Defines message content and structure |

A helpful analogy:

RS-485 is like the railway tracks, defining how trains move from station to station.

Modbus RTU is like the cargo manifest, detailing what each train car contains and how it should be processed.

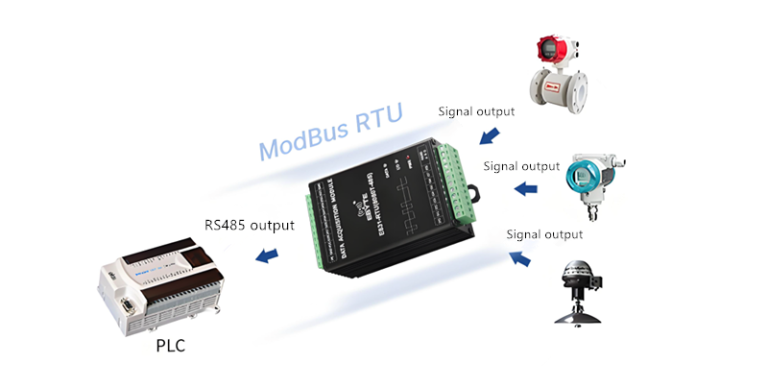

This combination allows engineers to implement reliable data communication among PLCs, sensors, drives, and actuators in harsh industrial environments.

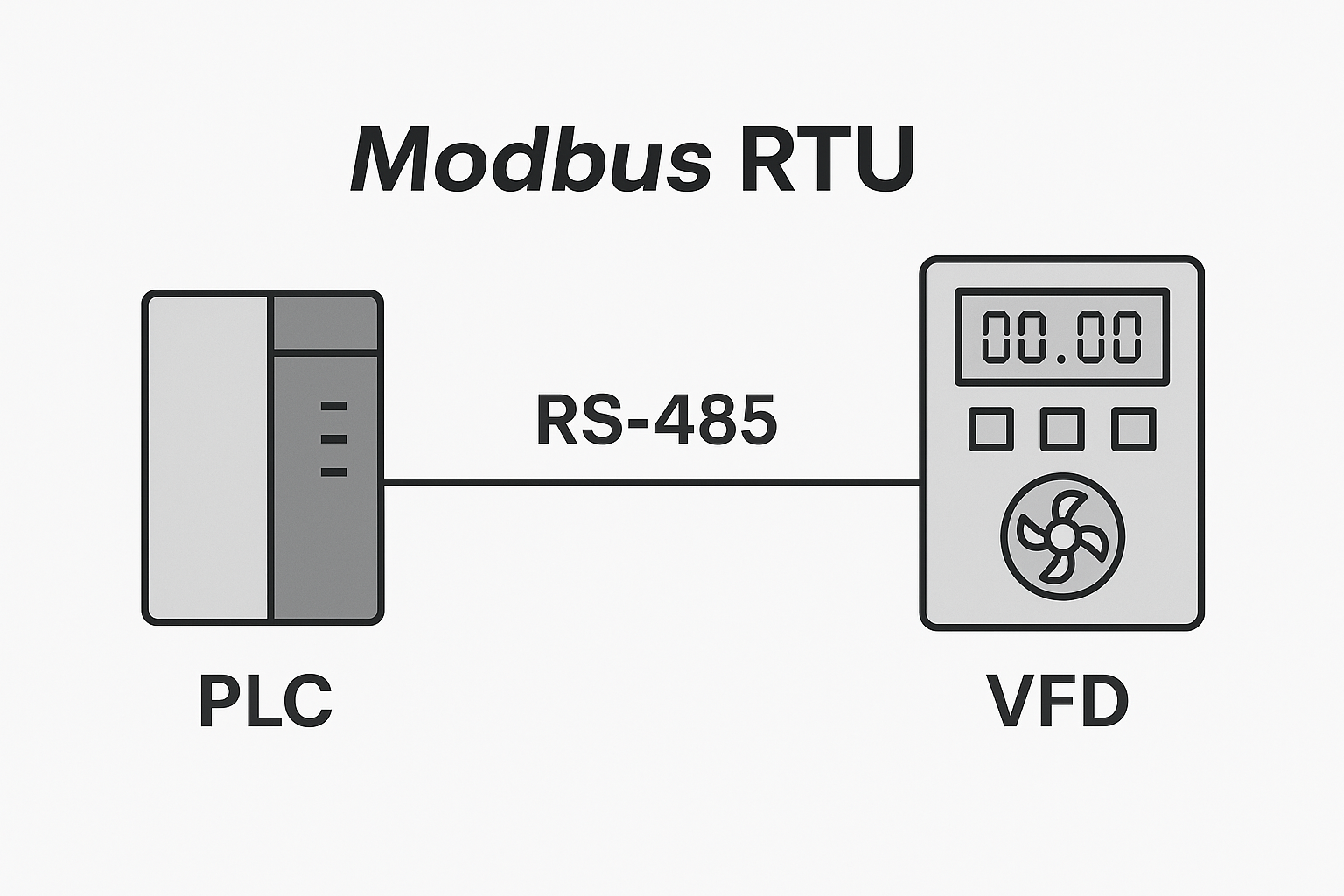

Example: RS-485-Based Modbus RTU Communication

Consider a scenario where a PLC controls a variable frequency drive (VFD) in a factory to adjust motor speed.

The PLC sends a command: “Set motor speed to 1500 RPM”

This command is wrapped in a Modbus RTU frame

The Modbus frame is transmitted via RS-485 as electrical signals

The VFD receives the frame, decodes it, and executes the speed change

If feedback is required, the VFD replies with a Modbus RTU response frame through RS-485, confirming the adjustment

In this setup, RS-485 acts as the communication pipe, and Modbus RTU ensures both devices “speak the same language.”

Conclusion: Hardware and Software Partners

Though Modbus RTU and RS-485 are often used together, they serve different functions:

RS-485 answers “how to transmit” — it’s a physical-layer standard

Modbus RTU answers “what to transmit” — it’s a data communication protocol

They form a hardware-software partnership, working hand in hand to support reliable and standardized industrial communication.