Layer of Protection Analysis (LOPA) is a semi-quantitative risk assessment tool commonly used in industries where safety and risk management are critical, such as chemical processing, oil and gas, and power generation. LOPA evaluates potential hazards and assesses whether the existing protective measures are sufficient to reduce the risk to acceptable levels. By quantifying the effectiveness of safety layers, LOPA allows companies to make informed decisions on whether additional protective measures are needed or whether existing ones can be optimized.

Overview of LOPA Process

LOPA is typically implemented after a preliminary qualitative hazard assessment, such as Hazard and Operability Study (HAZOP) or Failure Modes and Effects Analysis (FMEA). These preliminary studies help identify potential hazard scenarios, but they may not always provide detailed insights into the likelihood and severity of events. LOPA fills this gap by adding a quantitative element to risk assessment, enabling a more precise evaluation of risk.

Steps in Conducting LOPA

Identify Hazardous Scenarios

The first step in LOPA is identifying the potential hazardous scenarios. A hazardous scenario is any combination of equipment failure, human error, or other conditions that could lead to an accident or an unsafe situation. This often involves a detailed review of the initial hazard assessment documentation to pinpoint specific scenarios that need further examination.Determine the Initiating Event Frequency

An initiating event is the specific event that could trigger a hazardous scenario, such as a pump failure, a valve malfunction, or an operator error. Each initiating event has a frequency, often represented as events per year, that reflects the likelihood of occurrence. Accurate frequency estimation is crucial, as it serves as the foundation for calculating the risk of the scenario.Define the Consequence Severity

Once the initiating event is identified, the next step is to evaluate the potential consequences. Consequence severity is usually classified based on criteria such as potential for fatalities, environmental impact, financial loss, and reputational damage. Each organization may have its own criteria for consequence severity, and it is important to align these with company standards or regulatory guidelines. This step helps prioritize scenarios based on the severity of their potential impact.Identify Independent Protection Layers (IPLs)

LOPA is built around the concept of Independent Protection Layers (IPLs). IPLs are measures or systems that can prevent or mitigate the hazardous scenario, provided they are independent of the initiating event and other protection layers. For instance, a safety relief valve, an alarm system, or an emergency shutdown system might serve as IPLs, but they must function independently to be counted in the LOPA analysis.Quantify the Effectiveness of IPLs

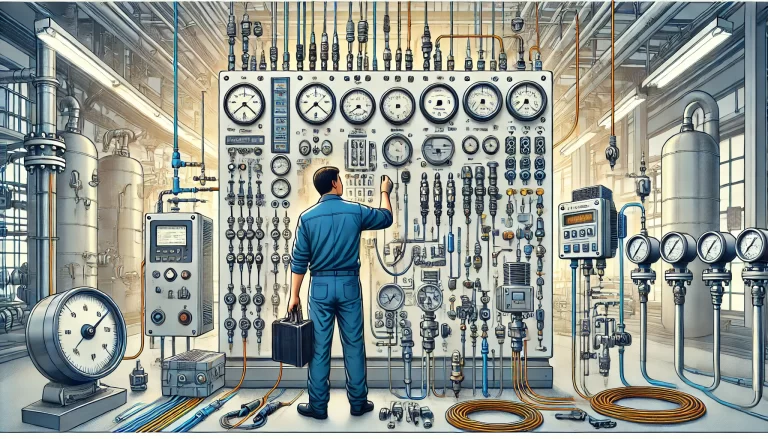

Each IPL has a Probability of Failure on Demand (PFD), which represents its effectiveness. The PFD indicates the likelihood that the IPL will fail when needed. Lower PFD values indicate higher reliability. For example, a PFD of 0.1 means the protection layer will work effectively 90% of the time when demanded. Standard IPLs and their typical PFD values include:- Safety Instrumented System (SIS): Typically has a PFD between 0.01 and 0.1.

- Operator Intervention: Often assigned a PFD of around 0.1 to 0.5, depending on training and situational factors.

- Physical Barriers: Depending on robustness, physical barriers can have PFD values ranging from 0.01 to 0.1.

- Emergency Response: Often has a higher PFD, around 0.5 or greater, due to the variable nature of human response.

Calculate the Remaining Risk

Using the initiating event frequency and the PFD values of the IPLs, LOPA allows calculation of the remaining risk. The remaining risk is determined by multiplying the initiating event frequency by the PFD of each IPL in sequence. This gives a quantifiable assessment of the risk level after considering the effectiveness of the IPLs.Remaining Risk=Initiating Event Frequency×∏(PFD of each IPL).

Compare with Acceptable Risk Criteria

After calculating the remaining risk, the result is compared against the organization’s acceptable risk criteria. Organizations often define these criteria based on industry standards, regulatory requirements, and internal safety policies. If the remaining risk is below the acceptable level, no further action may be required. However, if it exceeds acceptable levels, additional IPLs or other risk-reducing measures might be necessary.

Types of Independent Protection Layers

LOPA relies on a variety of independent protection layers, each designed to work independently to prevent or mitigate a hazardous event. Common IPLs include:

Inherent Safety Design: This approach involves designing the process or facility in a way that minimizes hazards at the source. For instance, using less hazardous materials or reducing the operating pressure in a system can serve as inherent safety layers.

Safety Instrumented Systems (SIS): These systems are designed to automatically detect and respond to unsafe conditions. SIS may include interlocks, emergency shutdown systems, and other automated responses that do not require human intervention.

Operator Actions and Procedures: Operators play a critical role in safety, especially in manual processes. Proper training, standard operating procedures, and regular drills can reduce the risk of human error and contribute to the overall effectiveness of protection layers.

Alarms and Control Systems: Alarm systems notify operators of abnormal conditions, allowing them to take corrective action before an incident escalates. Control systems, such as Distributed Control Systems (DCS) or Supervisory Control and Data Acquisition (SCADA), can automatically adjust process parameters to maintain safe conditions.

Physical Barriers and Containment: Physical barriers, such as firewalls or containment systems, limit the impact of hazardous events. They serve as passive protection layers that don’t require activation or monitoring to be effective.

Emergency Response Plans: These plans outline the procedures for responding to major incidents. Although not as reliable as automated systems, emergency response plans are essential for managing the consequences of incidents that do occur.

Applications of LOPA

LOPA is widely used in high-risk industries for various purposes, such as:

Post-Process Hazard Analysis: LOPA can be conducted after a preliminary process hazard analysis to deepen understanding of specific high-risk scenarios and provide more quantitative insights.

Cost Optimization in Safety Investments: By quantifying the effectiveness of different protection layers, LOPA helps organizations prioritize safety investments, ensuring that resources are allocated to the most critical risk-reduction measures.

Regulatory Compliance: Many regulatory bodies require a quantitative approach to risk management, especially in industries with high potential for severe accidents. LOPA helps meet these requirements by providing a structured framework for assessing and managing risk.

Conclusion

LOPA provides a structured approach for assessing risk in complex industrial processes by quantifying the frequency and severity of potential hazards and evaluating the effectiveness of existing protection layers. By following a clear methodology, LOPA enables companies to determine whether their risk is within acceptable levels or if additional safeguards are necessary. Through this process, organizations can not only meet regulatory standards but also enhance operational safety, thereby protecting employees, the environment, and company assets.