In industries where durability, hygiene, and safety are paramount, equipment must be able to withstand not just regular wear and tear but also harsh cleaning procedures. This is where the IP69K protection rating becomes essential. This rating, one of the most stringent in the IP (Ingress Protection) system, ensures that devices remain functional even under the toughest environmental conditions, including high-pressure, high-temperature water jets.

In this article, we’ll explore what the IP69K standard entails, how it compares to other IP ratings, and which industries rely on it.

What is an IP69K Rating?

The IP code, defined by the International Electrotechnical Commission (IEC) standard 60529, describes the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water. The IP69K rating, initially developed in Germany under the DIN 40050-9 standard, is now recognized globally as the highest level of protection against dust and water ingress.

Breaking Down IP69K:

- IP: Stands for Ingress Protection.

- 6: Indicates the device is completely dust-tight and offers the highest level of protection against solid particles.

- 9K: Specifies the device can resist high-pressure water jets at high temperatures from multiple angles.

Water Resistance Requirements of IP69K

What sets IP69K apart from other water-resistant ratings, such as IP67 or IP68, is that it must withstand intensive cleaning processes. This makes it suitable for applications where equipment needs to be sanitized or exposed to high-pressure washing frequently.

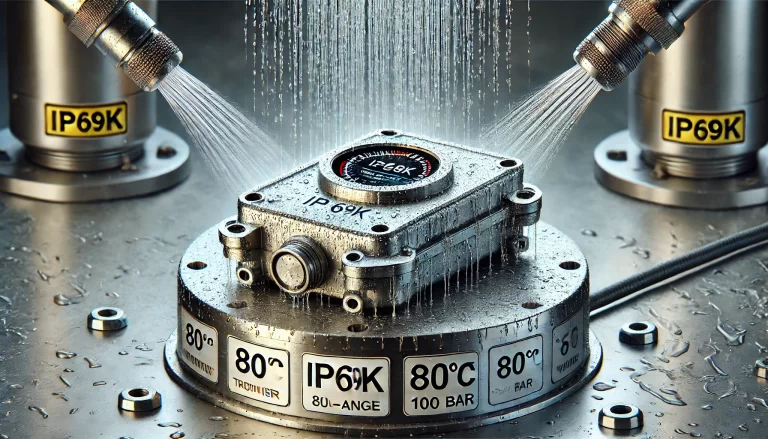

The water resistance test for IP69K involves:

- High-Temperature Water: Water used in the test is heated to 80°C (176°F).

- High Pressure: Water is sprayed at 8,000 to 10,000 kPa (80-100 bar), simulating extreme cleaning conditions.

- Flow Rate: The flow rate of the water is between 14 to 16 liters per minute.

- Close Proximity: The nozzle is placed approximately 10-15 cm (4-6 inches) from the surface of the device.

- Multi-Angle Testing: The device is exposed to water jets from various angles (0°, 30°, 60°, and 90°) to ensure comprehensive protection.

These rigorous conditions simulate real-world environments, especially in industries where regular sanitation with high-pressure water is required.

Comparison with Other IP Ratings

- IP67: Protection against dust and temporary immersion in water (up to 1 meter for 30 minutes).

- IP68: Protection against dust and continuous immersion in water beyond 1 meter.

- IP69K: Beyond immersion, this rating guarantees that a device can withstand intense high-pressure cleaning at elevated temperatures, making it ideal for extreme environments.

Applications of IP69K-Rated Equipment

1. Food and Beverage Industry

In food processing facilities, machinery and enclosures must be cleaned frequently to maintain hygiene standards. High-pressure, hot-water cleaning is often used to remove contaminants. Equipment such as stainless steel control panels, sensors, and conveyor systems often requires an IP69K rating to endure this cleaning process.

2. Automotive Industry

Vehicles like trucks, construction machinery, and agricultural equipment need to be pressure washed regularly to remove dirt, mud, and other debris. Components such as cameras, sensors, and lighting systems with an IP69K rating can withstand these cleaning routines without damage.

3. Pharmaceutical and Medical Equipment

Sterilization is crucial in the medical and pharmaceutical sectors. Devices that come into contact with patients or medicines need to be thoroughly sanitized, often with high-pressure steam and water, making IP69K equipment essential.

4. Outdoor Industrial Applications

In sectors such as mining, oil and gas, and transportation, harsh environments require robust equipment. IP69K-rated devices, such as outdoor control units, electronic displays, and sensors, are designed to operate reliably in dusty, dirty, and wet conditions.

Testing Procedure for IP69K Compliance

Testing to achieve an IP69K rating is meticulous. The device is placed on a rotating turntable to simulate exposure from all directions. It is then subjected to a high-pressure water jet at a 45° angle while being rotated. Each angle is tested for at least 30 seconds to ensure no water ingress occurs, making this test more challenging than a simple immersion test like IP67 or IP68.

Why IP69K is Important

The IP69K rating provides peace of mind in industries where reliability and sanitation are non-negotiable. By ensuring that a device can withstand the harshest cleaning protocols and environmental conditions, manufacturers can guarantee durability and reduce the risk of failure. This is especially critical in applications where equipment failure could lead to contamination, operational downtime, or safety risks.

Conclusion

The IP69K rating is the gold standard for equipment that must endure extreme environments and frequent high-pressure cleaning. It goes beyond simple dust and water resistance, ensuring that devices are protected against high-pressure, high-temperature water jets from multiple angles.

Industries such as food processing, automotive, pharmaceuticals, and outdoor industries rely heavily on IP69K-rated devices to maintain operational efficiency and hygiene standards. For businesses and manufacturers, choosing equipment with this rating ensures durability, compliance with safety and hygiene regulations, and long-term reliability, even in the harshest conditions.

When it comes to demanding environments where sanitation and performance are critical, IP69K-rated equipment stands as a benchmark of quality and resilience.