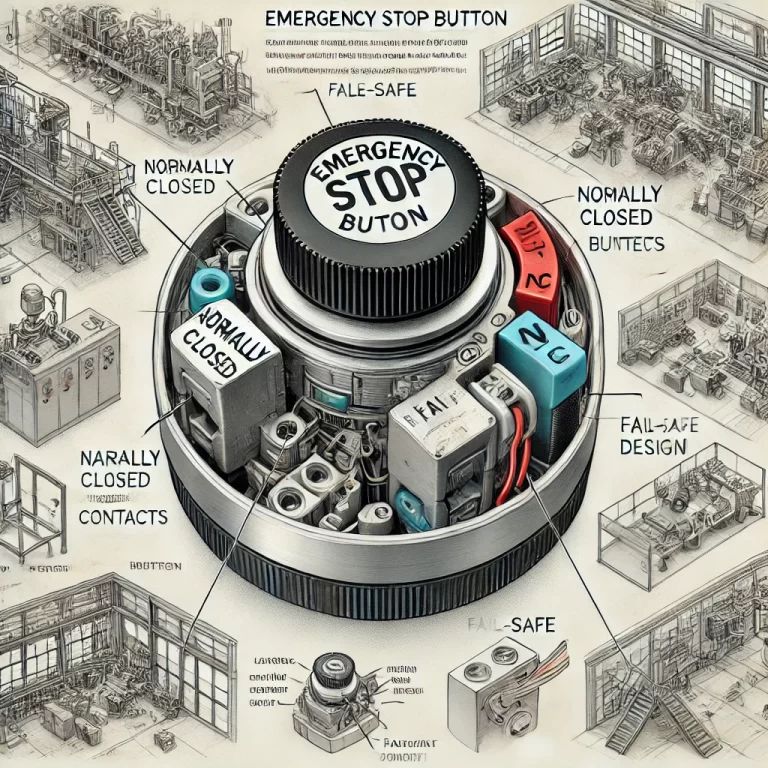

Emergency stop buttons, often referred to as “E-stop” buttons, are critical safety components in industrial machinery and electrical systems. Their main function is to allow immediate halting of machinery or electrical circuits in the case of an emergency. A key aspect of emergency stop button design is their use of normally closed (NC) contacts. This article will explore why normally closed contacts are used, how they operate, and what advantages they provide in ensuring safety and reliability.

1. The Basics of Normally Closed (NC) and Normally Open (NO) Contacts

In electrical circuits, switches and buttons can have two types of contacts:

- Normally Closed (NC): In a default state, the circuit is closed (allowing current to pass through), and pressing the button opens the circuit (stops current flow).

- Normally Open (NO): In a default state, the circuit is open (no current flow), and pressing the button closes the circuit (allows current to pass).

2. Why Emergency Stop Buttons Use Normally Closed Contacts

The primary reason for using normally closed contacts in emergency stop buttons is safety. Here’s how it works:

Fail-Safe Mechanism: In the default, non-activated state, a normally closed contact allows the electrical circuit to stay energized. However, when the button is pressed, the NC contact opens, instantly cutting off power to the machine. In this way, any intentional or unintentional pressing of the button ensures the machinery halts immediately.

Protection Against Wiring Failures: In the event of a wiring failure, such as a loose connection or damaged wire, the normally closed circuit would automatically open, triggering a shutdown. This “fail-safe” feature is critical, as it ensures that the equipment stops functioning if there is a fault in the circuit, which could otherwise go unnoticed.

Consistent, Immediate Response: Emergency situations require instant response. With NC contacts, the E-stop button acts instantly when pressed, which is essential in preventing accidents or minimizing damage.

3. How Emergency Stop Buttons with Normally Closed Contacts Work

Standard Operating Condition: In normal operation, the E-stop button remains unpressed, allowing current to flow through the circuit and power the machine. The machine operates under full control of the user or automated system, as the circuit remains closed.

Emergency Activation: When the button is pressed in an emergency, the NC contact inside the button opens, breaking the circuit. This causes power to the machine to cut off instantly, ensuring an immediate stop.

Restoring Operation: Most E-stop buttons are designed to “latch” in the pressed position, meaning they need to be manually reset before the machinery can resume operation. This latch prevents accidental restarting and requires a deliberate action to reset, adding a layer of safety.

4. Additional Safety Features and Configurations

Emergency stop buttons may also have additional safety features, depending on the application:

Dual Contacts: Some E-stops have both NC and NO contacts, allowing for simultaneous activation of a safety signal to a control system (using the NO contact) while interrupting power (using the NC contact).

Series Configuration: In complex machinery, multiple E-stop buttons may be wired in series. This configuration ensures that pressing any single E-stop button will break the circuit and stop the entire system.

Integrated Indicator Lights: Some buttons have indicator lights that illuminate when the button is pressed, providing a visual cue that an emergency stop has been activated.

5. The Importance of Emergency Stop Button Maintenance and Testing

Regular maintenance and testing of emergency stop buttons are essential to ensure they remain functional and reliable:

Testing: Periodic testing verifies that the NC contacts work correctly, and the machinery halts instantly when the button is pressed.

Visual Inspection: Inspect buttons for signs of wear or damage, which could impact their reliability. This includes checking wiring and making sure connections are secure.

Resetting Mechanisms: Ensure that latching mechanisms (if present) operate as intended and do not stick or jam.

Conclusion

Emergency stop buttons are fundamental safety components in any environment where machinery or electrical systems are in use. By utilizing normally closed contacts, they create a fail-safe environment that enhances safety, ensures immediate response in emergency situations, and protects against accidental restarts. This design principle helps meet international safety standards and plays a crucial role in accident prevention and operational reliability.