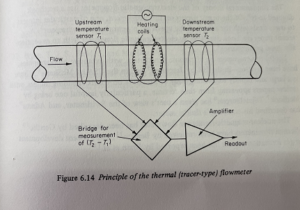

These are flowmeters-that is, instruments for determining the total flow rate in a pipe or duct-and must be confused with hot-resistor or hot-wire anemometers which are devices for measuring velocity at a point.

As will appear from Figure 6.14 they utilize the tracer-dilution principle, with heat acting as the injected tracer. It is obvious that other things being equal, the temperature rise(T2-T1) will be inversely proportional to the flow rate. Mass flow rate is given by

where H is the power supplied in the form of heat, and Cp is the specific heat capacity at constant pressure.

At present the main use for this type of flowmeters with gases at relatively low pressure and low flowrates-for instance, in small ventilating ducts and stacks. They cannot be used efficiently where the mass flow rate is high, because there they would consume an uneconomic amount of energy. Their accuracy and initial cost are moderate.

Just as some of Orwell’s animals were more equal than others, it would seem that some true mass flow rates are more true than others! There can be no disputing that the types described above, which are based solely upon fluid-mechanical principles, deserve to be called true mass flowmeters: they can be fed with practically any fluid, without even knowing what it is, and they will indicate the mass flow rate with reasonable accuracy.

Thermal mass flowmeters are often referred to as true mass flowmeters, but the appropriateness of this description in their case is somewhat questionable. Their output depends upon the heat-transfer properties of the fluid so that if, for instance, they are calibrated with natural gas having a certain composition, and subsequently the gas composition changes, they will give inaccurate readings. On the other hand, because the heat-transfer properties of a gas do not change very rapidly with changes in its density, they can be used with a given gas over a moderate range of temperature and pressure without too much loss of accuracy; this is why enthusiasts refer to them as true mass flowrates. In general, their performance suffers more from temperature changes than pressure changes, and by keeping the gas temperature fairly closely controlled it is possible to obtain an accuracy approaching ±1% over a wide range of flow rates.

Inferential methods of measuring mass flow

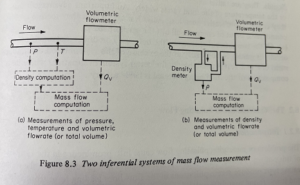

Two basically different systems for measuring mass flow inferentially are in use. They both use a conventional flowmeter to determine volumetric flow rate and /or total volume passed, but two different methods of density determination are involved.

The system shown in Figure 8.3a depends upon prior knowledge of the PVT properties of the fluid being metered-that is to say, the way in which the fluid’s specific volume varies with pressure and temperature. Pressure and temperature are both measured upstream of the flowmeter, and density is computed from these measurements. Then a second computation combines the density and the flowmeter reading to give mass flow.

In the other system of Figure 8.3b, some of the fluid is passed through a density meter before it enters the flowmeter. Thus density is determined directly, and then its value is combined with the flowmeter output as in the first system. When using this method, take care to ensure that (a)the temperature and pressure of the fluid in the densitometer are the same as in the flowmeter(a slight pressure difference can be tolerated if a correction is applied for it), and (b) that the fluid discharged from the densitometer does not create unacceptable inlet conditions at the flowmeter. Neglect of these precautions is a frequent cause of inaccuracy in systems of this kind.

Which method for which job?

Although there are always exceptions to any set of generalizations, the following guideline hold for the great majority of mass flow measurement situations.

(a) True mass flowmeters are best for low flow rates, but inferential systems for medium and high flow rates.

(b) The Wheatstone bridge meter is for use only with liquids, and its main field of use is for metering chemicals.

(c) Angular-momentum meters are most often used with liquids, and especially for metering fuel on aircraft, but they can also be used with gases.

(d) Thermal meters are primarily for use with gases, but can also be used with liquids. They are rather inaccurate in situations where either the composition or the temperature of the fluid varies widely. An important advantage is the considerable input of energy in all but the smallest sizes.

(e) Of the two inferential systems, the one based on the direct measurements of density is gaining in popularity at the expense of the systems based on measurement of P and T; it is undoubtedly the better system in situations where the composition of the fluid being metered is liable to vary.