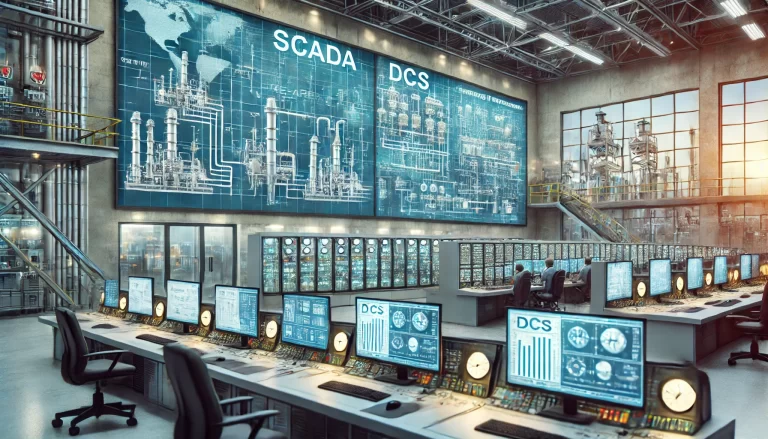

In the realm of industrial automation, accurate measurement and control of key physical parameters are essential for optimizing processes, maintaining safety, and ensuring product quality. Understanding these core measurement parameters allows industries to function with precision, efficiency, and reliability. The five most critical parameters in this context are pressure, temperature, flow, liquid level, and position/velocity. This article delves into each parameter, explaining its importance and the typical instruments used for measurement.

1. Pressure

Pressure is one of the fundamental parameters monitored in industrial settings. It measures the force exerted by a fluid or gas within a system and is crucial for the safe and efficient operation of equipment such as boilers, pipelines, and hydraulic systems.

Importance: Maintaining the correct pressure ensures that systems do not exceed their operational limits, which could lead to mechanical failures or safety hazards. Pressure control is also vital in applications such as chemical processing, where precise pressure regulation impacts the quality and yield of the final product.

Measurement Devices: Pressure sensors, transducers, and gauges are commonly used to monitor and control pressure. Devices such as strain gauge pressure sensors and piezoelectric sensors provide high accuracy for various industrial applications.

2. Temperature

Temperature control is ubiquitous in industrial processes, influencing product quality and system efficiency. Whether in food processing, chemical manufacturing, or power generation, maintaining optimal temperature is crucial.

Importance: Accurate temperature monitoring helps prevent overheating or freezing, which can damage equipment or affect the quality of materials. For instance, in pharmaceutical manufacturing, maintaining precise temperatures is necessary to ensure the efficacy of drugs.

Measurement Devices: Common temperature sensors include thermocouples, resistance temperature detectors (RTDs), and infrared sensors. Thermocouples are preferred for their wide temperature range and durability, while RTDs are known for their accuracy and stability.

3. Flow

Flow measurement refers to the determination of the rate at which a fluid or gas moves through a conduit. It is essential for managing processes that involve mixing, cooling, or chemical reactions.

Importance: Monitoring flow rates ensures that systems operate within desired specifications, aiding in process optimization and resource management. For example, accurate flow control in water treatment plants ensures that purification processes run efficiently, maintaining safe water supply levels.

Measurement Devices: Flow meters, such as electromagnetic, turbine, and ultrasonic flow meters, are commonly employed. Electromagnetic flow meters are particularly effective for measuring the flow of conductive fluids, while ultrasonic flow meters are used for non-invasive flow measurements.

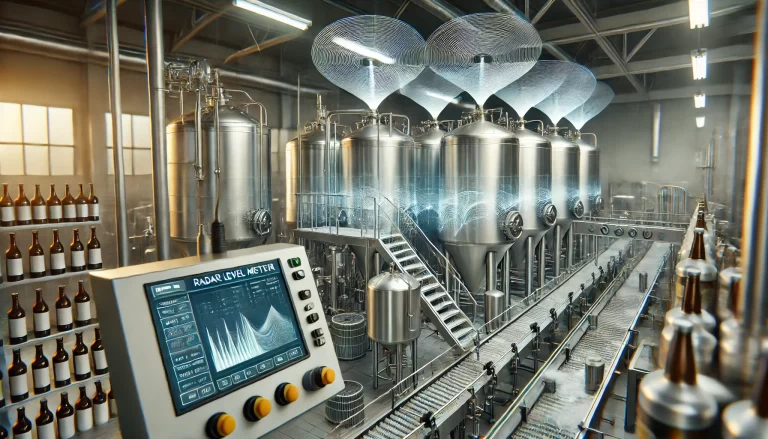

4. Liquid Level

Liquid level measurement is crucial in industries that rely on storage tanks, reservoirs, or process vessels. Maintaining the correct liquid level is essential for avoiding spillage, preventing pump damage, and ensuring consistent process output.

Importance: Ensuring the correct liquid level helps maintain process balance and prevents costly disruptions. In applications such as petrochemical refineries, accurate liquid level control can prevent hazardous overflows and ensure safe operations.

Measurement Devices: Devices such as ultrasonic level sensors, float switches, and capacitive level sensors are employed for various applications. Ultrasonic sensors are valued for their non-contact measurement capability, which reduces contamination risk and maintenance requirements.

5. Position and Velocity

Position and velocity measurements pertain to the movement of machinery or products within a system. These measurements are critical in automated processes involving robotics, conveyors, or CNC machines.

Importance: Monitoring position and velocity ensures precise control of equipment, leading to efficient operation and high-quality output. In automotive assembly lines, for instance, the precise control of robotic arms ensures the accurate placement of parts and components.

Measurement Devices: Position sensors such as linear variable differential transformers (LVDTs), potentiometers, and optical encoders are used to detect and monitor movement. Velocity can be measured using tachometers or rotary encoders, which provide feedback on the speed of rotating parts.

Conclusion

In summary, the core measurement parameters of pressure, temperature, flow, liquid level, and position/velocity are indispensable to industrial automation. Mastery of these parameters and their corresponding measurement technologies empowers industries to enhance productivity, ensure safety, and maintain high standards of product quality. Understanding the function and application of relevant sensors and instruments is fundamental for engineers and technicians working to optimize complex industrial processes.