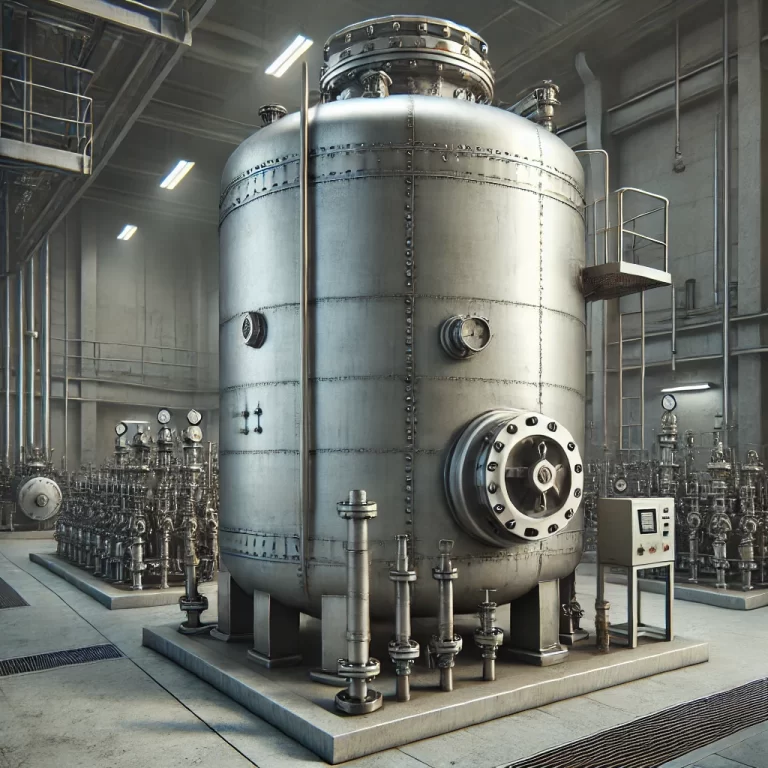

In the food processing industry, the dissolution process of raw materials in dissolution tanks has a direct impact on the quality of the final product. As an advanced non-contact level measurement technology, radar level meters have become widely used in various complex environments due to their high accuracy, stability, and strong anti-interference capabilities, including in the dissolution tanks of the food industry.

Importance of Accurate Level Measurement in Food Processing

Dissolution tanks are essential in food processing, where they are used to dissolve solid ingredients into solutions for subsequent processing stages. In this process, accurate monitoring of liquid level changes in the tank is crucial for ensuring product quality and production efficiency. Traditional level measurement methods often struggle with precision and are easily affected by environmental factors. However, the emergence of radar level meters provides a more reliable solution for level measurement in dissolution tanks.

Radar level meters function by emitting microwave signals and capturing the reflections that return from the liquid surface to determine the level. This operating principle allows them to deliver accurate level data even in challenging conditions, such as those involving steam, foam, or viscous media—factors that typically hinder traditional measurement methods. Additionally, radar level meters perform non-contact measurements, meaning they do not contaminate the chemicals in the dissolution tanks, making them particularly suitable for the food industry, which has stringent hygiene standards.

The Advantages of Radar Level Meters Over Other Measurement Methods

In comparison to other methods, such as float-type or ultrasonic level meters, radar level meters excel in several ways:

- Accuracy and Stability: Radar level meters offer higher precision and remain unaffected by temperature, pressure, and changes in tank content composition, ensuring consistent measurements under varying conditions.

- Adaptability to Complex Media: These meters can handle various substances, including mixtures of sugar, salt, acids, and bases, commonly found in dissolution tanks. They continue to provide precise readings even in high-temperature and high-pressure environments where chemical reactions might alter the liquid level.

- Minimal Maintenance: Being a non-contact device, radar level meters reduce wear and the risk of contamination. This decreases maintenance requirements and reduces downtime for cleaning and repairs, helping facilities maintain a higher level of productivity.

Application Examples in the Food Industry

In practical applications, such as beverage production, dissolution tanks are used to dissolve sugar and other additives in water to form the base liquid. If the level control is inaccurate, it could result in an incorrect sugar concentration, affecting both the taste and quality of the beverage. With radar level meters, manufacturers can monitor level changes in real time, ensuring the precision and consistency of the dissolution process.

This precision has a measurable impact on product quality and production efficiency. For instance, in some facilities, switching to radar level meters has resulted in reduced fault occurrences and less frequent shutdowns, while also allowing for more consistent product quality.

Future Prospects for Radar Level Meter Technology in Food Processing

With ongoing advancements in radar level meter technology, more food processing companies are expected to adopt this reliable and efficient level measurement technology. Improvements in radar sensor sensitivity and processing algorithms are likely to further enhance their accuracy and adaptability. As the food industry continues to prioritize quality, hygiene, and operational efficiency, radar level meters will play an increasingly critical role in helping manufacturers remain competitive in a highly regulated market.