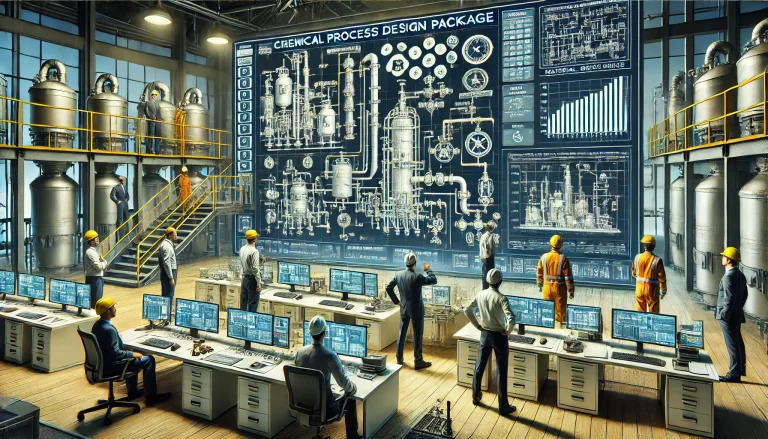

This document outlines the risks associated with common operations in the instrumentation field and provides detailed preventive measures to ensure operational safety and accuracy. It serves as a guide for engineers and technicians to mitigate risks in various instrumentation tasks.

1. Equipment Power Shutdown and Activation

Risks:

- Confusion between similar devices (e.g., A/B systems).

- Simultaneous or unintended operation of adjacent switches or fuses.

Preventive Measures:

- Ticket Approval:

Ensure proper documentation through an operational ticket system, specifying the exact system and device tag numbers. Devices with similar identifiers (e.g., “A/B systems”) must be clearly distinguished. - Double Verification:

- Always perform operations with two personnel.

- Double-check the target equipment for shutdown.

- Single Device Isolation:

- Verify that no other devices are connected to the switch or fuse being operated.

- Inspect for sticky or faulty components before operation to prevent unintended actions.

- Position Identification:

For a row of switches or visually similar components:- Confirm the circuit using tag numbers and wire labels.

- Ensure the correct alignment with the intended circuit.

2. Instrument Cable Disconnection and Reconnection

Risks:

- Process monitoring disruptions.

- Misidentification of devices during operations.

Preventive Measures:

- Process Monitoring Assurance:

- Obtain a work permit for any operation affecting process monitoring.

- Validate protective measures (e.g., interlock bypasses) with process personnel.

- Device Identification:

- Match tag numbers, descriptions, and locations precisely before operation.

- In complex systems (e.g., A/B/C devices), confirm via system readings or control room displays.

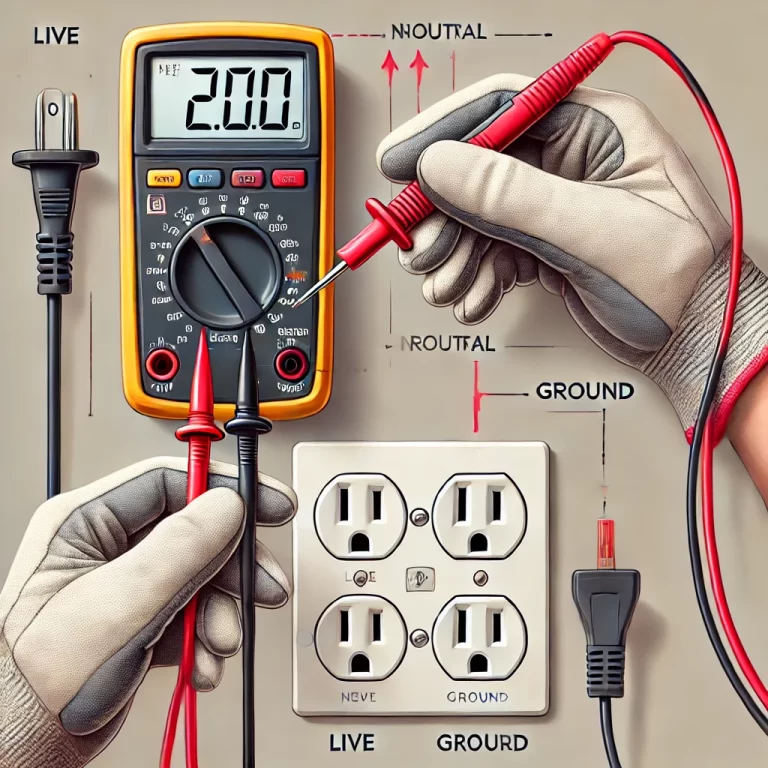

- Power Isolation for Powered Devices:

- For devices like solenoid valves and four-wire instruments, ensure they are powered down before operation. Never perform maintenance on live equipment.

3. Instrument Draining and Purging

Risks:

- Fluctuations in readings.

- Leakage of hazardous media, causing burns or poisoning.

Preventive Measures:

- Operational Necessity:

- Perform draining or purging only when necessary, with prior approval from the workshop.

- Personnel must be familiar with the properties of the medium and use appropriate protective equipment.

- Risk Mitigation:

- Double-check safeguards (e.g., interlock bypass) to prevent unintended actions or fluctuations in process values.

- Device Matching:

- Verify tag numbers and locations. If systems are complex, cross-check with control room readings.

4. System Downloads and Updates

Risks:

- System-wide instability or shutdown.

- Incorrect operations in similar systems (e.g., A/B systems).

Preventive Measures:

- Comprehensive Risk Assessment:

- Use a multi-layer approval process before downloading updates.

- Develop detailed operational plans to address potential risks.

- Double-Personnel Verification:

- Ensure two people (e.g., team leader and technician) are present to validate the operation.

- Detailed Records:

- Take photographs of changes in the system before initiating downloads and share them for group verification.

- Timing Considerations:

- Perform downloads during periods of high alertness (e.g., mid-shift). Avoid end-of-shift or pre-holiday periods to prevent errors caused by fatigue or inattention.

5. Measurement Point Forcing

Risks:

- Triggering unintended interlocks or alarms.

- Extended forcing durations leading to oversight.

Preventive Measures:

- Documentation:

- Log forced points clearly and precisely, including the system-confirmed tag numbers.

- Simulation and Testing:

- Collaborate with process personnel to simulate the expected forcing results before implementation.

- Confirm positions (e.g., source or intermediate variables) to ensure effectiveness.

- Routine Inspection:

- Maintain records of forced points and perform weekly reviews with process teams. Limit forcing duration to avoid accidental oversight.

6. Interlock Debugging

Risks:

- Overlooked or unintended actions causing system disruptions.

Preventive Measures:

- Approval and Coordination:

- Obtain a maintenance permit and involve process teams during debugging.

- Pre-review interlock logic to identify potential triggers and actions.

- Cross-Functional Synchronization:

- Conduct debugging collaboratively with DCS and process teams using a single interface to prevent communication delays or misunderstandings.

- Restricted Operations:

- DCS personnel should refrain from operating valves or pumps directly. Such operations must be handled by process teams.

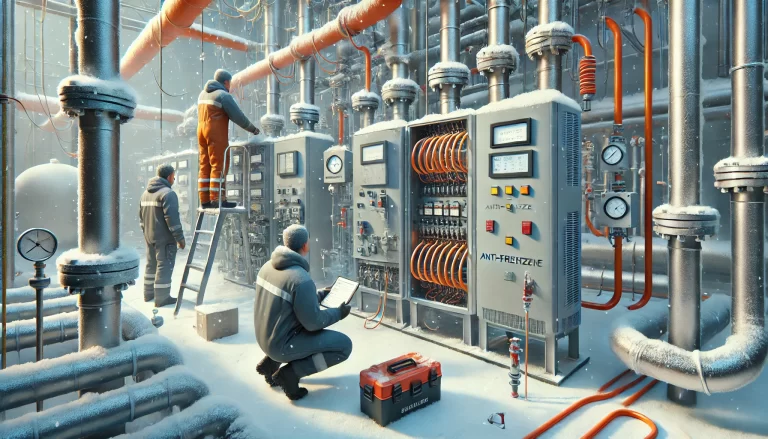

7. Air Supply Shutoff and Restoration

Risks:

- Multiple valve movements due to shared air supply lines.

- Sudden changes in process conditions.

Preventive Measures:

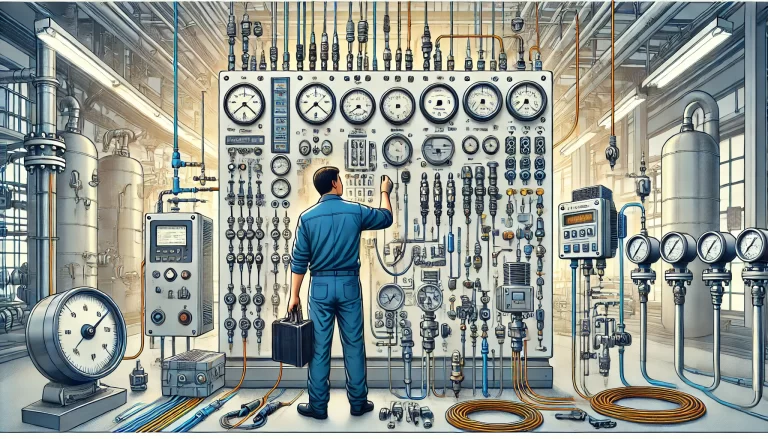

- Systematic Checks:

- From the air supply source to valve connections, verify whether multiple valves are connected to a single air supply line.

- Controlled Operations:

- Perform air supply changes gradually, allowing time for process stabilization.

8. Interface Disconnection and Reconnection

Risks:

- Medium leakage or pressure hazards.

Preventive Measures:

- Pre-Work Inspections:

- Validate the correct interface and secure approval from process teams before operation.

- Controlled Execution:

- Depressurize and isolate connections before disconnecting.

- Avoid standing in line with potential leak paths.

Appendix:

- Example Ticket Template: Includes fields for system identifier, device tag numbers, personnel approvals, and risk mitigation steps.

- Regulatory References: Links to applicable industry standards and regulations.

- Case Studies: Analysis of past incidents with recommendations for future prevention.