1. Introduction

In high-temperature or high-humidity industrial processes, steam and condensation can significantly affect the measurement accuracy and reliability of radar level transmitters. Water droplets or condensate films on the antenna surface may attenuate the radar signal, causing unstable readings or complete signal loss. This document outlines proven preventive and corrective measures to mitigate these effects, ensuring long-term stable operation.

2. Preventive Measures

2.1 Select Appropriate Antenna Type and Device Specifications

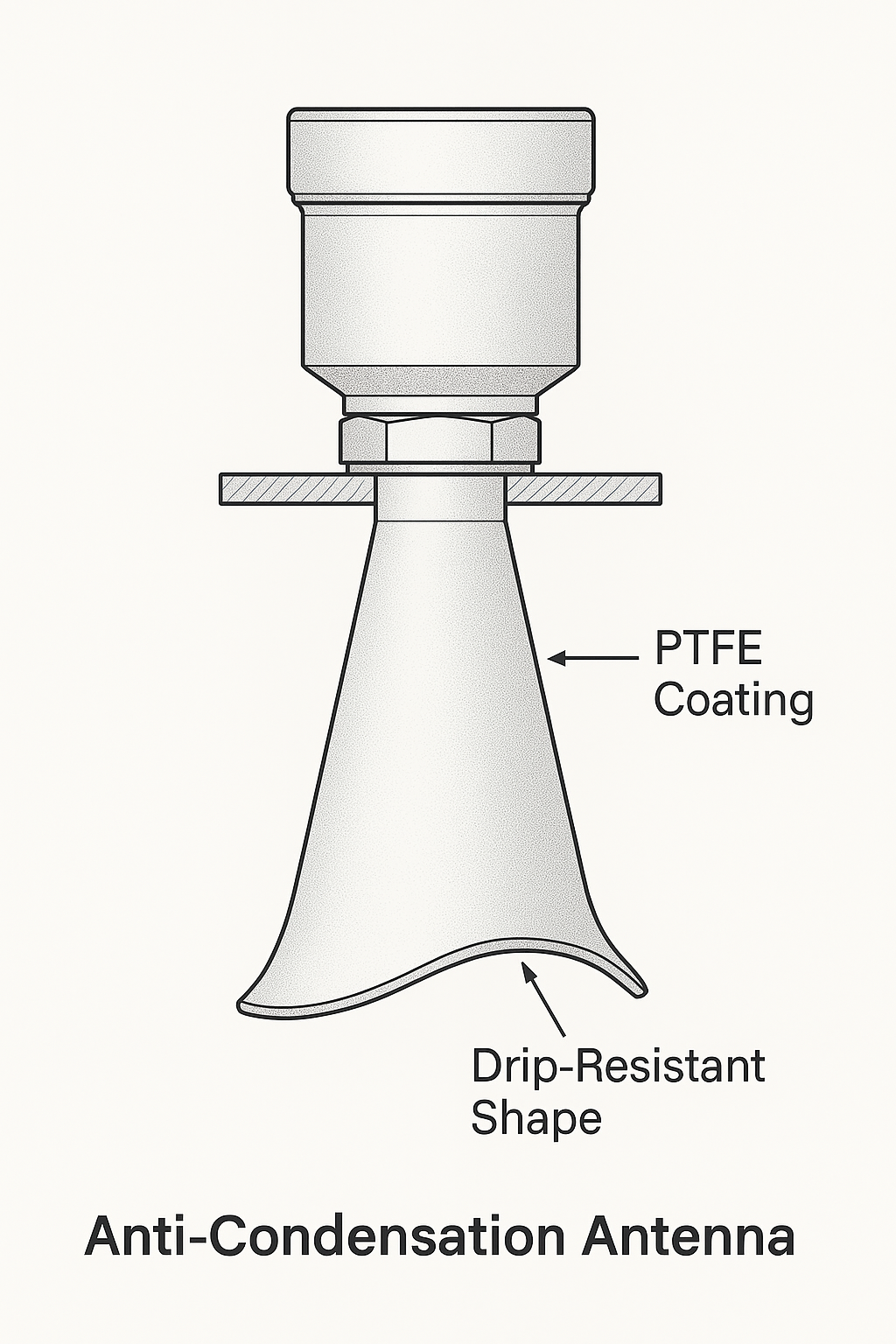

Use large-diameter horn antennas or models with anti-condensation coatings (e.g., PTFE/Teflon) to reduce steam adhesion.

For environments with high steam temperatures, select devices with temperature resistance ≥150 °C to prevent component degradation.

Consider non-contact radar with a drip-resistant antenna design to minimize water droplet accumulation.

2.2 Optimize Installation Method

Guided wave tubes: Use 316L stainless steel, smooth inner walls, and an internal diameter ≥50 mm to reduce signal attenuation. The length should cover the full measuring range.

Reserve a drain port at the tube bottom for periodic removal of condensate or deposits.

Tilt installation: Angle the antenna 3–5° downward to facilitate natural water runoff, reducing droplet retention.

2.3 Implement Protective Measures

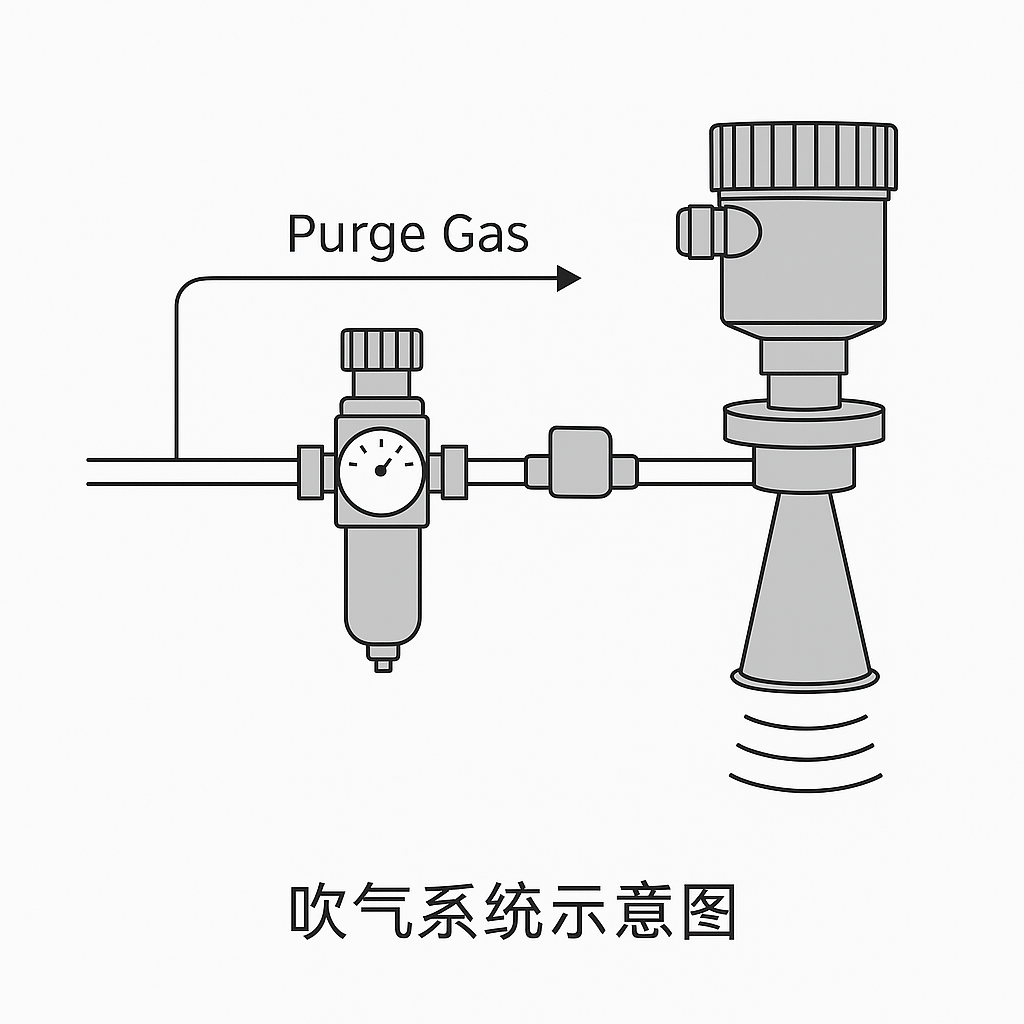

Purge system:

Use dry nitrogen with a dew point ≤ –40 °C.

Avoid steam purging, as it may worsen condensation.

Maintain purge pressure at 0.1–0.3 MPa, with a flow rate sufficient to form a stable air curtain at the antenna opening.

Install a filter and pressure regulator to prevent contaminants from entering the system.

Thermal insulation and localized cooling:

Insulate tanks or pipelines to keep the radar installation area above the medium’s dew point.

For unavoidable steam exposure, add a cooling jacket to lower steam concentration near the antenna.

3. Corrective Measures

3.1 Antenna Heating

Select radar models equipped with an integrated antenna heating element to evaporate condensate and maintain a dry antenna surface.

3.2 Scheduled Cleaning

Perform manual cleaning of the antenna surface based on operating conditions to remove residual condensate and deposits formed due to condensation.

3.3 Drainage Design in Guided Wave Tubes

Ensure drain ports are regularly opened to release trapped condensate, preventing false echoes within the waveguide.

4. Conclusion

By combining proper equipment selection, optimized installation, environmental control, and routine maintenance, the negative impact of steam and condensation on radar level measurement can be significantly reduced. These practices help ensure accurate, stable, and long-term measurement performance in challenging industrial environments.