In modern industrial production, the storage and management of liquids are crucial, especially when dealing with corrosive liquids such as acids. Accurate and reliable level measurement is not only essential for production efficiency but also directly impacts safe operations. Radar level meters, with their unique non-contact measurement method, have become an ideal choice for measuring the level in acid storage tanks.

Radar level meters operate based on the principle of emitting and receiving electromagnetic waves. They emit electromagnetic waves into the container through an antenna system. When these waves encounter the liquid surface, they are reflected back and received by the same antenna. By calculating the time taken from emission to reception and factoring in the speed of electromagnetic wave propagation, the liquid level can be determined. This process is not affected by the properties of the medium, allowing for precise measurements even in complex conditions involving viscous liquids, foam, or steam.

Advantages of radar level meters:

- Non-contact measurement: Avoids direct contact with corrosive liquids, significantly extending the instrument’s service life and reducing maintenance costs.

- High precision: Provides stable measurement data even under harsh conditions.

- Easy installation and maintenance: Simple structure, no complicated wiring or drilling, greatly simplifying the installation process. The robust design also means low maintenance needs.

- Strong anti-interference capability: Unaffected by temperature or pressure changes and resistant to external electromagnetic interference.

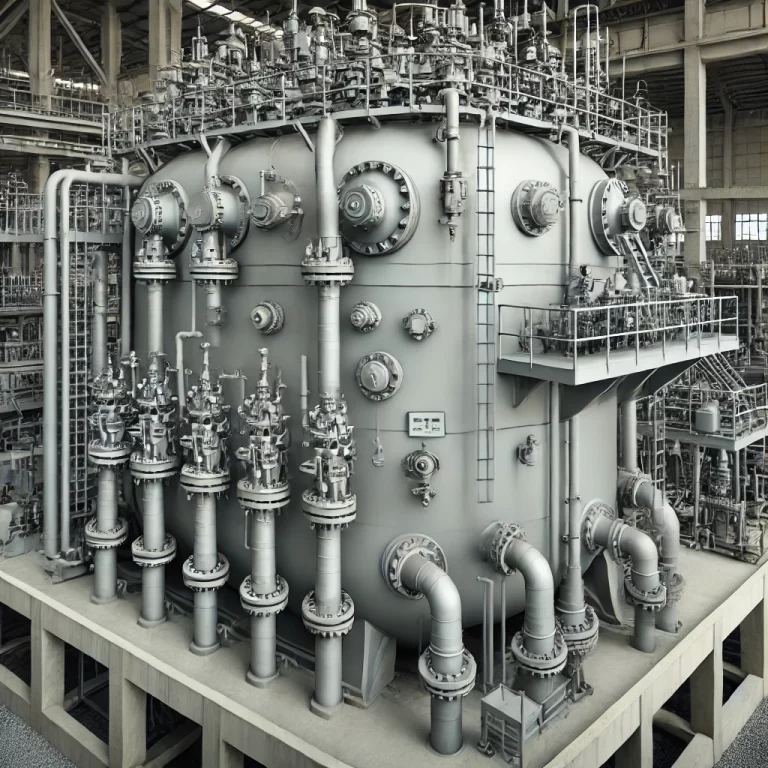

In a chemical plant, controlling the liquid level in sulfuric acid storage tanks has long been a challenge. Due to sulfuric acid’s strong corrosiveness and volatility, traditional level meters often suffer from damage and inaccurate readings. The introduction of radar level meters solved these issues. Installed at the top of the storage tank, away from corrosive acid vapor, the radar level meter transmits electromagnetic waves into the tank and receives the reflected signal to measure the liquid level. Even in conditions where significant vapor is produced by sulfuric acid evaporation, the level can be measured accurately, ensuring continuous and safe production.

Considerations when choosing a radar level meter:

- Medium characteristics: Including corrosiveness, viscosity, and whether vapor is present.

- Storage tank structure: Such as the tank’s height, diameter, and presence of agitators.

- Environmental conditions: Including temperature, pressure, and potential electromagnetic interference.

During installation, the radar level meter’s antenna should be aligned with the center of the tank, avoiding locations near inlets, agitators, or other areas that may cause surface fluctuations. Additionally, the seal and connections should be periodically checked to ensure safe and reliable operation.

With their non-contact measurement, high accuracy, and strong anti-interference capabilities, radar level meters demonstrate outstanding performance in measuring the liquid level of acid storage tanks. Proper selection, installation, and regular maintenance ensure safe and efficient industrial production.