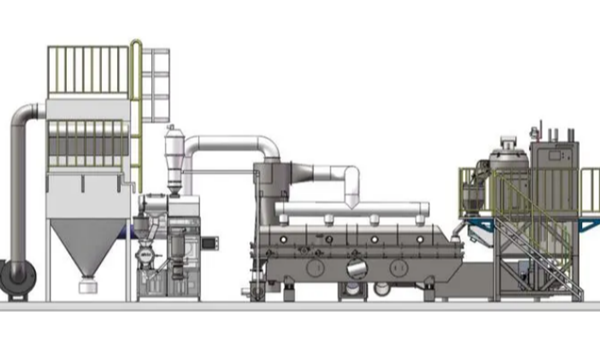

Fluidized bed granulator is one of the important chemical equipment, and radar level meter is a popular level measurement instrument in the market. Many users ask whether radar level meter can measure the level of fluidized bed granulator. This article will analyze it in detail!

During the operation of the fluidized bed granulator, the material forms a fluidized state under the action of high-speed airflow, so that the particles grow evenly.

The level changes in this process are fast and complex, and traditional contact measurement methods are often difficult to adapt to this environment.

In contrast, the radar level meter measures the level by emitting microwave signals and receiving their reflected waves. It can not only achieve non-contact measurement, but also work stably in harsh environments such as high dust and high temperature.

The level characteristics in the fluidized bed granulator are mainly reflected in the following aspects:

First, the height of the level will continue to change with the progress of the granulation process, which requires the measurement equipment to have the ability to monitor in real time. Secondly, due to the growth of particles and the influence of airflow, the level surface is often not a flat interface, but presents an irregular fluctuation state.

In addition, the uneven density distribution of materials in the fluidized bed also poses challenges to the accurate measurement of the level.

In view of these characteristics, the application of radar level meters needs to consider the following technical points. The first is the choice of frequency. High-frequency radar level meters can provide narrower beam angles, which helps to reduce interference from surrounding structures and improve measurement accuracy.

The second is the optimization of signal processing algorithms. By adopting advanced data processing technology, the true position of the level surface can be effectively identified, and stable measurement results can be obtained even in the case of large fluctuations.

The third is the precise design of the installation position.

A reasonable installation position can avoid the influence of airflow on radar wave propagation and ensure the stability of the measurement signal.

In practical applications, radar level meters also need to face the challenges of environmental factors such as high temperature, high humidity and possible corrosive gases inside the fluidized bed granulator.

Therefore, the selection of materials with high temperature and corrosion resistance to manufacture radar level meters, as well as regular maintenance and calibration of the equipment, are important measures to ensure long-term stable operation.

In summary, the level measurement of fluidized bed granulators is a complex and critical process. Radar level meters, with their advantages of non-contact measurement, have demonstrated remarkable performance in meeting this challenge.

Through the continuous optimization of radar level meter technology and the accumulation of application experience, we have reason to believe that in the future industrial production process, radar level meters will play a more important role in the level monitoring of fluidized bed granulators.