Due to the special structure and operation mode of PEM electrolytic cells, many liquid level meters have problems in measuring the liquid level of PEM electrolytic cells. As an advanced measuring instrument, the radar level gauge has become an ideal choice for measuring the liquid level of PEM electrolyzers due to its non-contact measurement and high-precision measurement characteristics. We will introduce the working principle of radar level gauges, analyze the difficulties in measuring PEM electrolyzers, and illustrate the application of radar level gauges in PEM electrolyzer level measurement through actual measurement cases.

Let’s take a look at the difficulties of liquid level measurement in PEM electrolyzers. Corrosive environment: PEM electrolyzers are usually filled with corrosive liquids such as strong acids and alkalis. Traditional liquid level gauges cannot withstand this harsh environment and are prone to corrosion and Give way.

High-pressure environment: PEM electrolyzers will generate high pressure during operation, which places higher requirements on the safety and stability of measuring equipment. Large temperature fluctuations: The temperature inside the electrolyzer fluctuates greatly, which affects the physical properties of the liquid and the accuracy of the measuring equipment.

Effect of bubbles and foam: Bubbles and foam in the electrolyzer will affect the propagation and reflection of microwave signals, leading to measurement errors. Radar level gauges use the transmission and reception of microwave pulses to measure liquid level.

Microwave pulses are emitted through the antenna and reflected back when encountering the liquid surface and are received by the receiver. By measuring the time difference between the emitted wave and the reflected wave, combined with the known wave speed, the liquid level is calculated. Radar level gauge has the characteristics of non-contact measurement, high precision and high reliability, and is suitable for various harsh industrial environments.

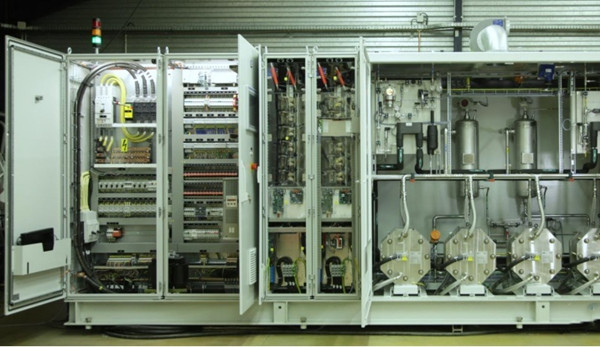

A chemical plant uses radar level gauges to measure the liquid level of its PEM electrolyzer. Considering factors such as corrosion, high pressure and temperature fluctuations, a radar level gauge with corrosion resistance, high strength and high stability was selected.

This radar level gauge is equipped with special anti-corrosion coating and high-temperature-resistant materials to adapt to the harsh environment inside the electrolyzer.

During the installation process, in order to prevent the microwave signal from being affected by air bubbles and foam inside the electrolytic tank, a waveguide is used to protect the radar antenna. The waveguide can guide the microwave signal to propagate along the tube wall to avoid direct contact with the liquid in the electrolyzer. At the same time, the waveguide can also stabilize the liquid level and reduce the impact of liquid level fluctuations on measurement accuracy.

Through comparison of actual operating data, the chemical plant found that the radar level gauge has high accuracy and stability in PEM electrolyzer liquid level measurement.

It not only meets the requirements of the production process, but also greatly improves the production efficiency. In addition, radar level gauges have low maintenance costs and long service life, saving factories a lot of maintenance costs.

As an advanced measuring instrument, radar level gauge has significant advantages in PEM electrolytic tank level measurement. Through reasonable selection and installation of radar level gauges, the difficulty of liquid level measurement in PEM electrolyzers can be effectively solved and production efficiency and product quality can be improved.