Pulse signals are widely used in Distributed Control Systems (DCS) to trigger one-time actions such as valve actuation, counter increments, reset commands, and interlock releases. Selecting the proper pulse type—short or long—and determining appropriate pulse duration are essential to ensure reliable operation, prevent false triggering, and avoid missed actions.

This article explains the engineering rules, typical application scenarios, and practical methods for pulse-time determination.

1. Fundamental Rules for Selecting Pulse Signals

A pulse signal is essentially a temporary state transition (0→1→0 or 1→0→1) used to initiate a single event. The selection must comply with the following principles:

1.1 Compatibility with the Controlled Device

The pulse must match the device’s input characteristics:

Effective state: High-level or low-level activation

Trigger edge: Rising-edge or falling-edge sensitive

Electrical requirements: Voltage level, sourcing/sinking, isolation

Examples:

If a solenoid valve requires high-level activation, the pulse must output a high signal.

If a counter module only responds to the rising edge, the pulse must be configured accordingly.

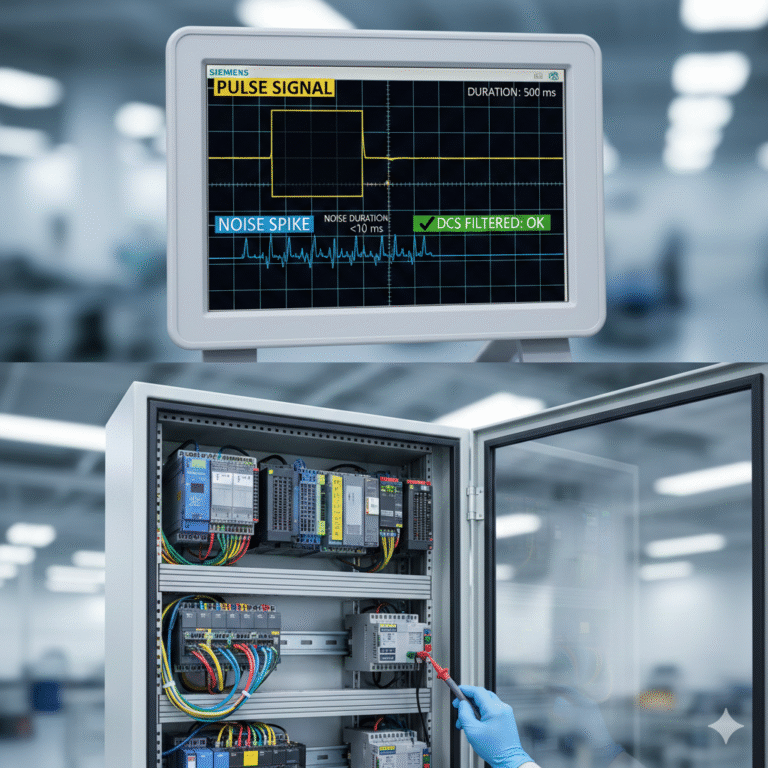

1.2 Anti-Interference Considerations

Pulse signals must be immune to field noise caused by motors, VFDs, long cable runs, etc.

Therefore:

Pulse width must be longer than typical noise spikes (noise pulses are often <10 ms).

DCS filtering functions (debounce, delay-on, confirmation timers) should be applied.

1.3 One-Time Action Requirement

A pulse should only trigger one event, not maintain or repeat it.

Example:

If a pulse is used to start a pump, the pump should continue running after the pulse ends. The pulse must not be long enough to cause double-start or repeated commands.

1.4 DCS Scan Cycle Adaptation

If pulse duration is shorter than the DCS scan cycle, the system may miss it.

Rule of thumb:

Pulse time ≥ 1.5 × DCS scan cycle

Example:

DCS scan cycle: 20 ms

Minimum pulse width: 30 ms

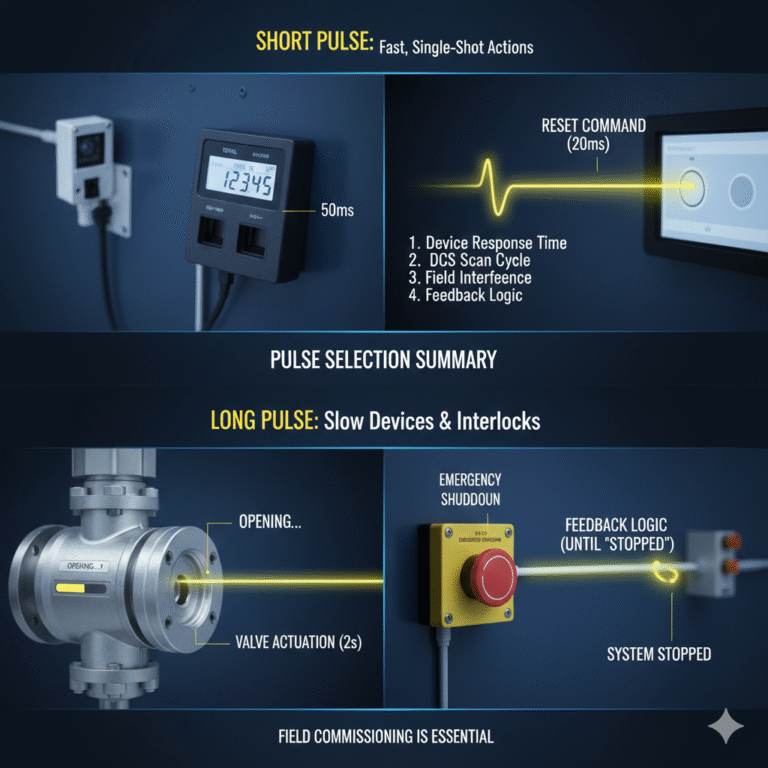

2. Application Scenarios for Short vs. Long Pulses

Pulse duration is typically divided into two categories (actual values vary by system):

Short pulse: 10–100 ms

Long pulse: 100 ms – several seconds

Choosing between them depends on device response time and logic requirements.

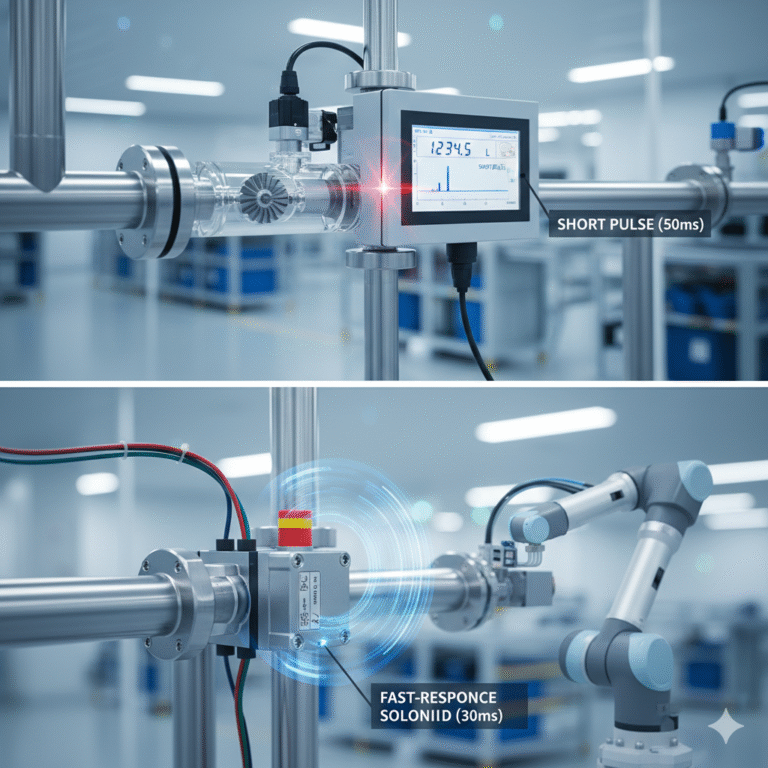

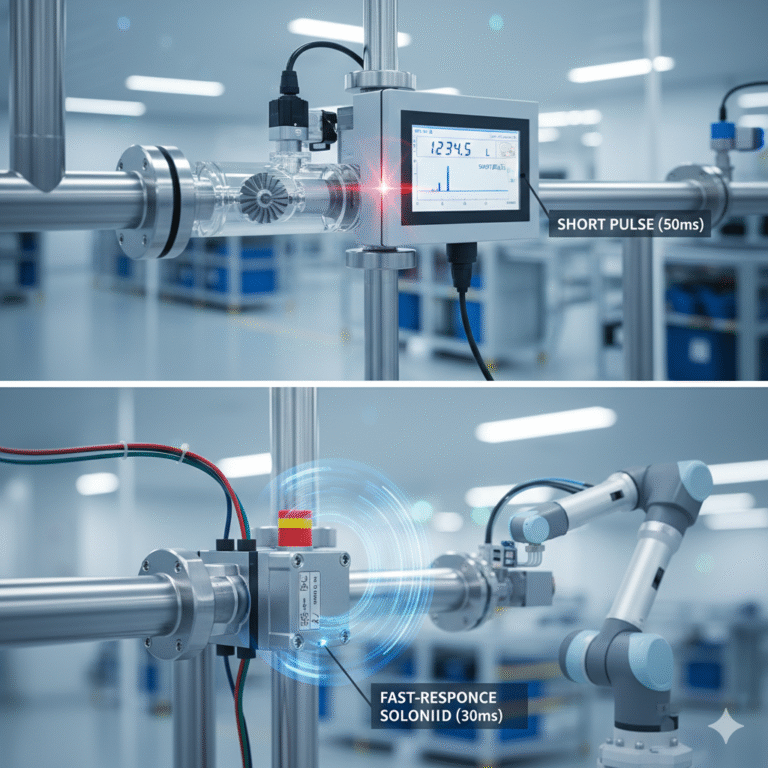

2.1 When to Use Short Pulses

Short pulses are used when fast triggering is required and repeated activation must be avoided.

Typical scenarios:

(1) Flowmeter or counter pulses

Used for:

Flow totalization

Conveyor belt weighing

Speed measurement

Short pulses avoid multiple counts caused by long signal durations.

(2) Reset or acknowledge commands

Examples:

PID mode switch reset

Alarm acknowledge

System reset commands

Short pulses guarantee single execution and avoid logic oscillation.

(3) Fast-response devices

Devices with reaction times <50 ms:

Small solenoid valves

Photoelectric sensors

Proximity switches

A short pulse is enough for proper recognition.

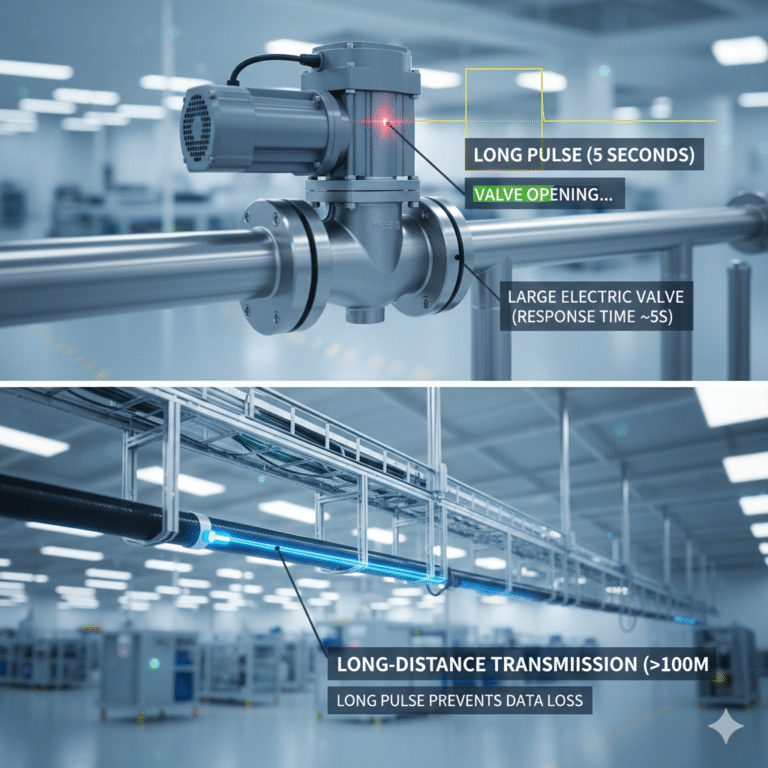

2.2 When to Use Long Pulses

Long pulses are required when the controlled equipment responds slowly or the system must ensure the command is fully received.

Typical scenarios:

(1) Large valve open/close commands

Large pneumatic or electric valves often require:

200 ms–1 s to begin motion

Up to several seconds to reach full stroke

Pulse must cover the minimum response time (e.g., 1–2 s).

(2) Interlocks requiring feedback confirmation

Example:

Emergency shutdown (ESD) commands that must persist until the feedback “Stopped” is received.

If the pulse is too short, the device may fail to complete the shutdown sequence.

(3) Long-distance signal transmission

When signals travel through cables >100 m, attenuation or minor delays may occur.

Long pulses reduce the risk of lost or unrecognized commands.

3. How to Determine the Proper Pulse Duration

Pulse duration must be determined based on equipment specifications, system characteristics, and site conditions. The following method is recommended.

3.1 Use the Device’s “Minimum Response Time”

This is the shortest time the device needs to detect a command and begin acting.

Rule:

Pulse width ≥ minimum response time × (1.1 – 1.5 safety margin)

Example:

A motorized valve requires 300 ms to react → pulse should be 330–450 ms.

3.2 Consider DCS Scan Period and Filtering

Pulse must be at least 1.5 × scan cycle

Should exceed the duration of site noise pulses (>10–20 ms recommended)

3.3 Consider Logic and Feedback Requirements

If the pulse triggers an action that requires feedback (e.g., valve “Open Confirmation”), then:

Pulse width must ≥ maximum feedback delay

ORUse logic: “Maintain pulse until feedback is received”

Example:

Valve open time = 5 s → pulse duration = 5 s

(or use “pulse until feedback” logic)

3.4 Verify Through Field Testing

If the device does not respond → pulse is too short

If it responds multiple times → pulse is too long

Field tuning is essential.

Conclusion

Selecting pulse signals in a DCS is a balance between reliability and accuracy.

In summary:

Short pulses → fast, single-shot actions (e.g., counters, resets, fast solenoids)

Long pulses → slow devices, interlocks, long cable runs

Pulse duration should be based on:

Device response time

DCS scan cycle

Field interference

Feedback logic

Final settings should always be validated through field commissioning.