When filling an instrument isolation chamber with ethylene glycol antifreeze, it is crucial to consider whether the antifreeze needs to be diluted with water. The decision largely depends on the type of antifreeze used, the environmental conditions, and the specifications of the equipment. Below is a detailed guide to help ensure optimal performance and protection.

1. Type of Antifreeze

a. Concentrated Ethylene Glycol Antifreeze

Concentrated antifreeze requires dilution with water before use. The dilution ratio depends on the desired freezing point and the environmental conditions. Common dilution ratios are 1:1 (equal parts antifreeze and water) or 2:1 (two parts antifreeze to one part water), with the specific ratio often listed on the product label. For instance:

- A 1:1 ratio typically protects down to approximately -37°C (-34°F).

- A 2:1 ratio offers more protection for extremely cold environments, often as low as -52°C (-62°F).

b. Pre-Mixed Antifreeze

Pre-mixed antifreeze is already blended with water at an optimal ratio (usually 50% antifreeze and 50% water). This type is ready to use directly without any additional dilution, saving time and eliminating the risk of incorrect mixing.

2. Environmental Conditions

The environmental temperature plays a critical role in determining the appropriate antifreeze concentration.

- Mild climates (above -20°C/-4°F): A lower concentration (e.g., 40% antifreeze, 60% water) might suffice.

- Severe climates (below -30°C/-22°F): Higher concentrations or undiluted antifreeze may be necessary to prevent freezing and maintain equipment functionality.

Additionally, the concentration affects the antifreeze’s boiling point, which is important in systems exposed to high temperatures. While higher concentrations improve freeze protection, they may slightly reduce heat transfer efficiency. Balancing these factors is essential.

3. Equipment Requirements

Instrument isolation chambers may have specific requirements regarding the fluid used. Consult the equipment’s operation or maintenance manual to confirm:

- The recommended concentration of antifreeze.

- The maximum allowable viscosity and any restrictions on additives to ensure compatibility with the chamber’s design.

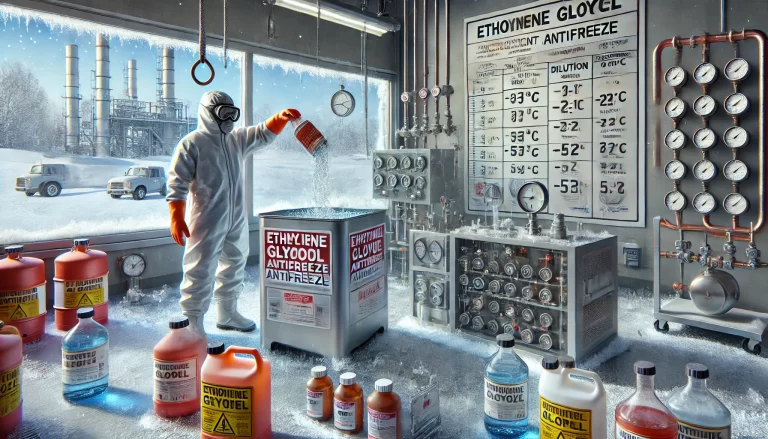

4. Preparation and Mixing

If dilution is required, follow these steps to prepare the antifreeze solution:

- Use the Right Water: Always use distilled or deionized water for mixing. Tap water may contain minerals that can cause scaling, corrosion, or deposits in the chamber.

- Mix Thoroughly: Combine the antifreeze and water in a clean container and mix well to achieve a homogeneous solution.

- Test the Mixture: Use a hydrometer or refractometer to verify the concentration aligns with the required freezing point for your environment.

5. Additional Considerations

- Corrosion Protection: Ethylene glycol antifreeze also acts as a corrosion inhibitor. If the concentration is too low, it may compromise the equipment’s protection against rust and degradation. Adhering to the manufacturer’s guidelines ensures adequate anti-corrosion properties.

- Regular Maintenance: Periodically check the antifreeze solution in the isolation chamber to ensure it remains within the desired concentration range and replace it as recommended. Over time, the solution may degrade, reducing its effectiveness.

- Safety Measures: Ethylene glycol is toxic. Handle it with care, wear protective equipment, and prevent spillage. Ensure proper disposal according to local regulations.

Conclusion

Properly managing ethylene glycol antifreeze in an instrument isolation chamber is critical for ensuring reliable operation and equipment longevity. Whether to dilute antifreeze depends on its type and the specific operational needs of your system. By considering environmental factors, equipment requirements, and proper mixing techniques, you can maintain optimal performance while protecting the chamber from freezing and corrosion.