Introduction

In industrial equipment management, Preventive Maintenance (PM) and Predictive Maintenance (PdM) are two commonly adopted strategies. While the two terms differ by only a single word, they represent fundamentally different approaches to equipment reliability. This article compares their definitions, advantages, limitations, and suitable applications, helping enterprises choose the right maintenance strategy—or a combination of both.

1. Preventive Maintenance (PM)

1.1 Definition

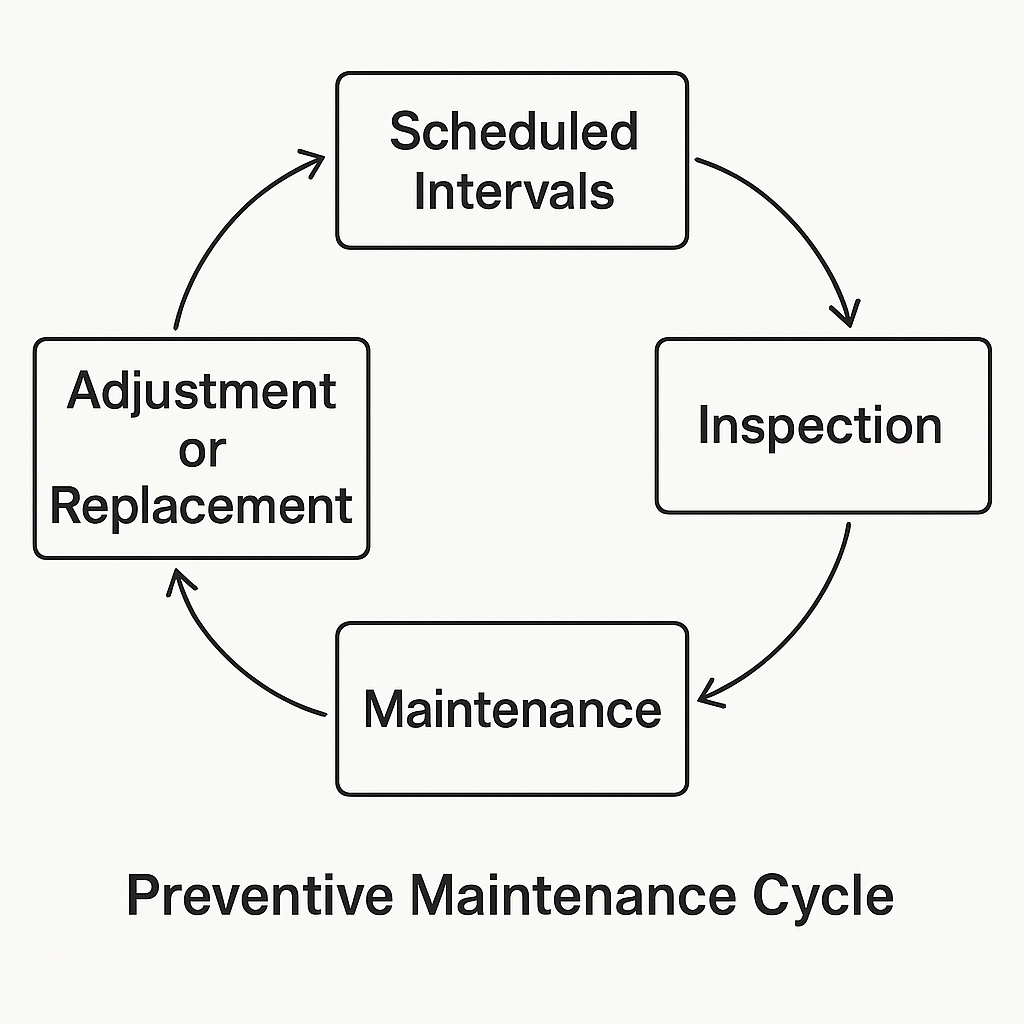

Preventive Maintenance is a time-based or usage-based strategy. Maintenance tasks—such as inspections, lubrication, adjustments, and part replacements—are performed at scheduled intervals (e.g., after a fixed number of operating hours, cycles, or mileage).

Example: Regular oil changes and tire inspections on a vehicle after a specified distance.

1.2 Advantages

Reduced risk of unexpected failures: Routine checks can reveal hidden defects, e.g., insulation resistance tests on motors detect aging before short circuits occur.

Extended equipment lifespan: Timely lubrication and alignment minimize wear and extend service life.

High predictability: Maintenance schedules are easy to plan, allowing resource allocation for manpower, spare parts, and training.

1.3 Limitations

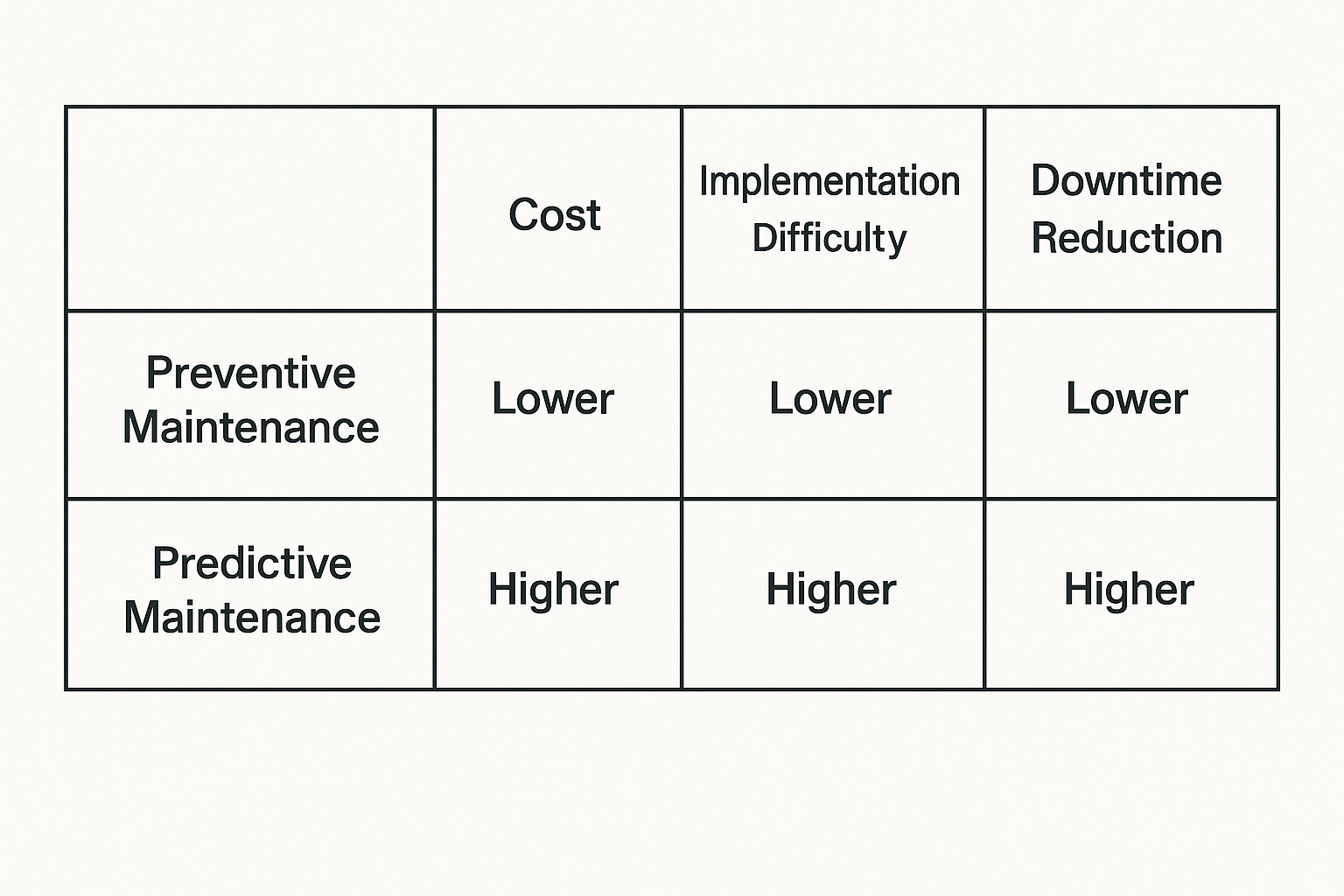

Over-maintenance risk: Components may be replaced prematurely even if they remain in good condition, leading to wasted cost and downtime.

Insensitive to actual condition: Preventive schedules ignore variations in environment or stress. Equipment in harsh conditions may fail sooner than the schedule anticipates, while equipment in favorable environments may be maintained too often.

2. Predictive Maintenance (PdM)

2.1 Definition

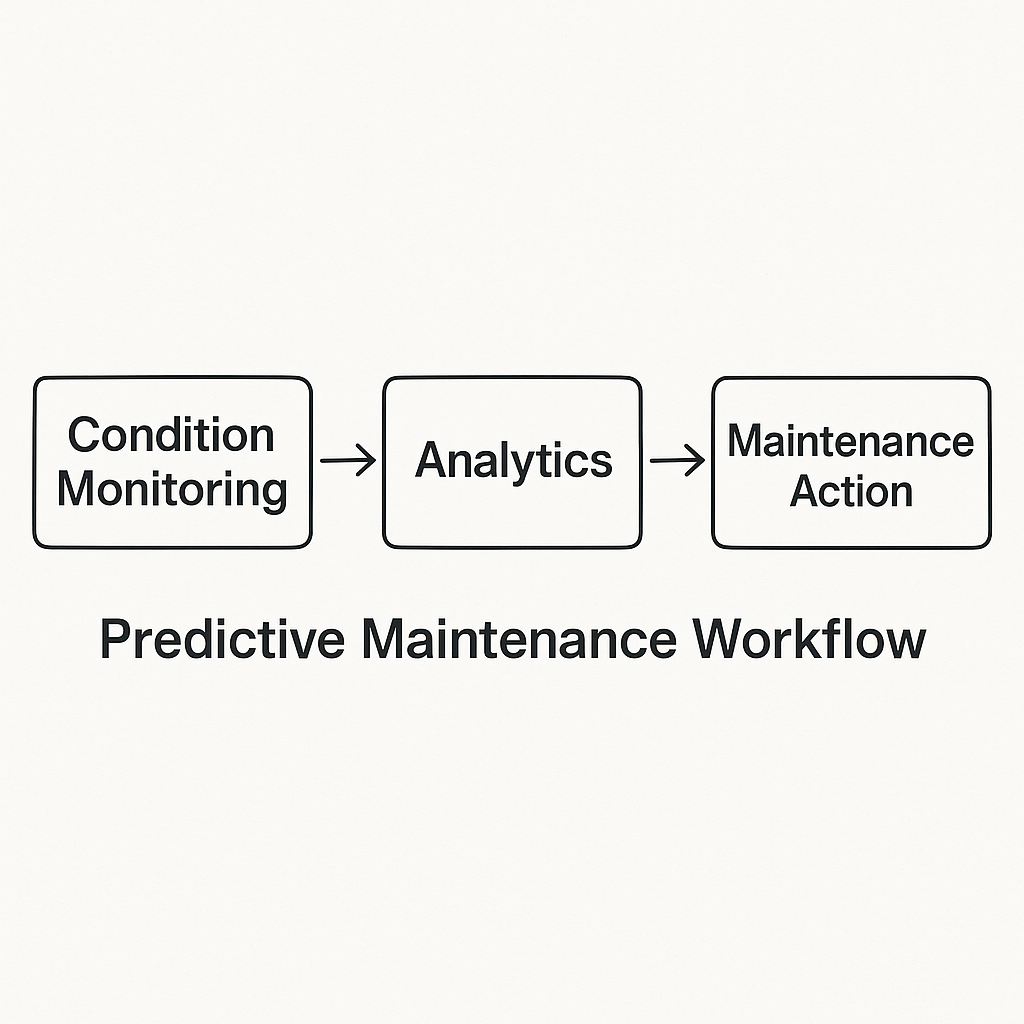

Predictive Maintenance relies on real-time condition monitoring. Using sensors and analytics, it continuously measures parameters such as vibration, temperature, and current. Advanced algorithms (machine learning, AI) predict potential failures, allowing maintenance to be performed only when truly necessary.

Example: Detecting abnormal vibration frequencies in motors before mechanical failure occurs.

2.2 Advantages

Condition-based precision: Tasks are triggered only when deterioration indicators appear, avoiding both over- and under-maintenance.

Reduced unplanned downtime: Failures can be predicted and addressed before they cause costly shutdowns, especially in continuous process industries.

Improved reliability and product quality: By keeping equipment in optimal condition, production runs more consistently.

2.3 Limitations

High technical requirements: Requires sensors, data acquisition systems, and skilled analysts. For example, vibration monitoring demands high-accuracy sensors and expertise in signal analysis.

High implementation cost: Hardware, software, and human resources may burden smaller organizations.

Complex implementation: Different equipment types demand customized monitoring strategies and models.

3. Comparison and Strategy Selection

3.1 Applicability

Preventive Maintenance: Suitable for equipment fleets, stable operating environments, or resource-limited enterprises where simplicity and predictability matter.

Predictive Maintenance: Best for critical, high-value, or safety-sensitive assets such as aerospace, nuclear power, or petrochemical industries.

3.2 Hybrid Approach

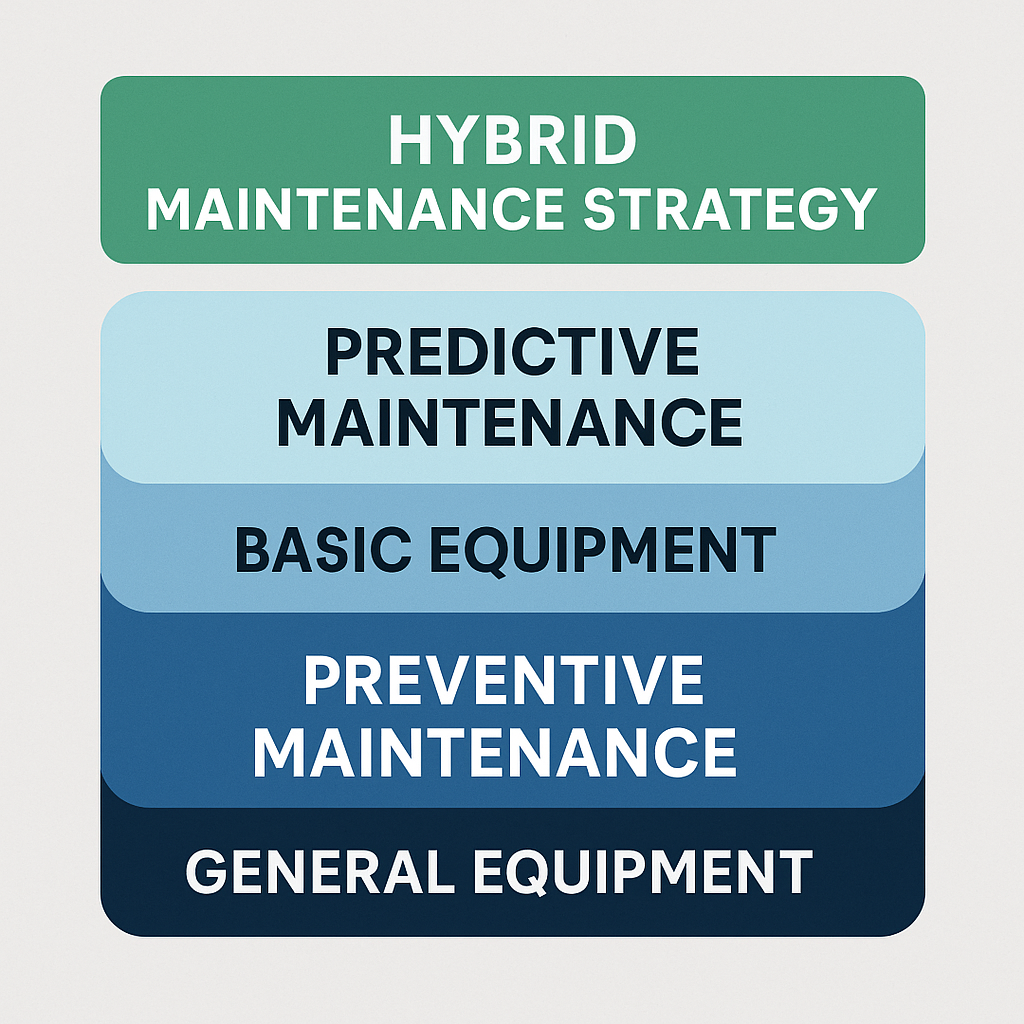

In practice, many organizations adopt a hybrid strategy:

Basic, general-purpose tasks (lubrication, visual checks) are managed by Preventive Maintenance.

Critical components and failure-prone parts are monitored with Predictive Maintenance.

This combination balances cost-effectiveness with high reliability.

Conclusion

Both Preventive and Predictive Maintenance play essential roles in modern industrial operations. While Preventive Maintenance offers simplicity and predictability, Predictive Maintenance delivers precision and efficiency. The choice depends on equipment criticality, operational risk tolerance, and available resources. When applied together, they form a robust maintenance framework that improves reliability, reduces downtime, and supports long-term asset management.