In industrial applications, the accuracy of temperature measurements directly impacts product quality, production safety, and process stability. However, many people have encountered issues such as inaccurate temperature readings despite choosing the right instruments, frequent rework due to improper installation, or even safety risks caused by selecting the wrong components in hazardous environments. In this guide, we’ve compiled essential information on the classification, selection, and installation of temperature measurement instruments to provide a practical roadmap. Whether you’re a newcomer to the field or an experienced engineer, this guide will help you avoid common pitfalls and save you 90% of the effort!

1. Types of Temperature Measurement Instruments by Measurement Method

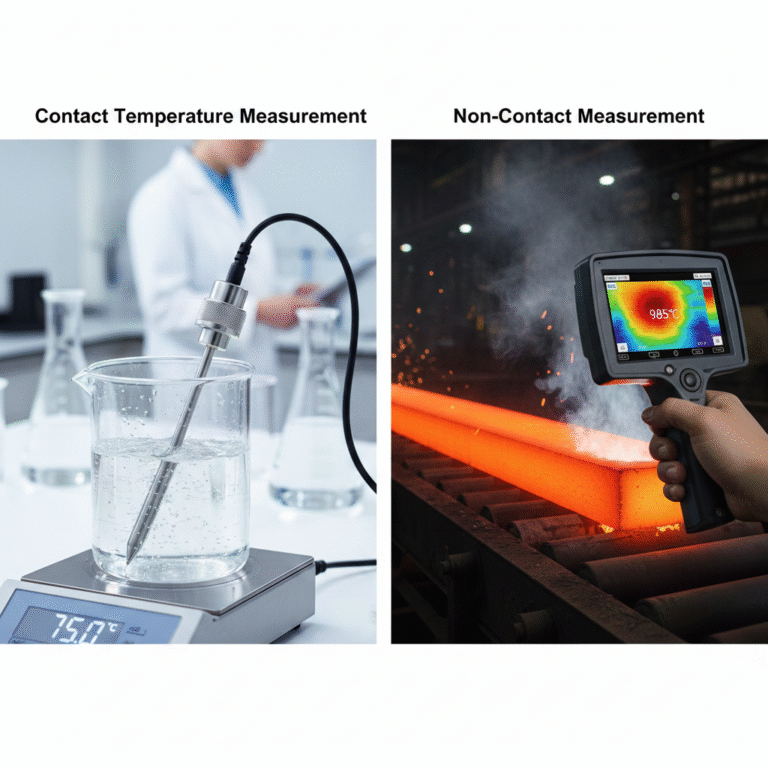

Temperature measurement instruments can be categorized into two types based on the method of measurement: contact and non-contact instruments.

Contact Temperature Instruments

Contact instruments measure temperature by ensuring that the sensing element is in direct contact with the object being measured, allowing thermal equilibrium to occur. These instruments are generally simple, reliable, and highly accurate. However, they have a delay in response due to the time it takes for thermal equilibrium to be reached. Additionally, they are limited in measuring very high temperatures due to the materials used for the sensing element.

Non-contact Temperature Instruments

Non-contact instruments measure temperature by sensing the heat radiation or electromagnetic properties of the object without direct contact. These instruments have no upper limit for temperature measurement and do not disturb the thermal field of the object being measured, allowing for quicker responses. However, their accuracy can be influenced by external factors such as the emissivity of the object, measurement distance, smoke, water vapor, dust, etc.

2. Types of On-Site Temperature Measurement Instruments and Their Applications

On-site temperature measurement instruments include bimetallic thermometers, glass thermometers, and pressure-type thermometers.

Bimetallic Thermometers: Typically used for general purposes. A 100mm scale diameter is suitable for most installations, while a 150mm diameter is preferred for higher or farther installations.

Glass Thermometers: Best for situations where precise measurements are required with minimal vibration. These thermometers are also easy to read.

Pressure-type Thermometers: Recommended for:

Measuring temperatures as low as -30°C.

Locations with distances greater than 6m or those obstructed by ceiling or floor installations.

Vibration-prone environments.

3. Choosing Between Thermocouples and RTDs

When selecting temperature sensors, it’s essential to consider the following factors:

Thermocouples have a broader temperature range and are ideal for high-temperature environments. They are more robust and better suited for vibration-prone applications.

RTDs (Resistance Temperature Detectors) offer higher accuracy and are preferred for applications with low temperatures and minimal vibration.

Other Selection Criteria:

For high-hydrogen gas measurements above 870°C, choose a blow-type thermocouple or tungsten-rhenium thermocouple.

To measure the surface temperature of equipment or pipelines, use surface thermocouples or surface RTDs.

When multiple temperature points need to be monitored (e.g., catalytic layers), opt for multipoint thermocouples.

In hazardous environments, choose explosion-proof thermocouples or RTDs.

4. Installation Guidelines for Accurate Temperature Measurement

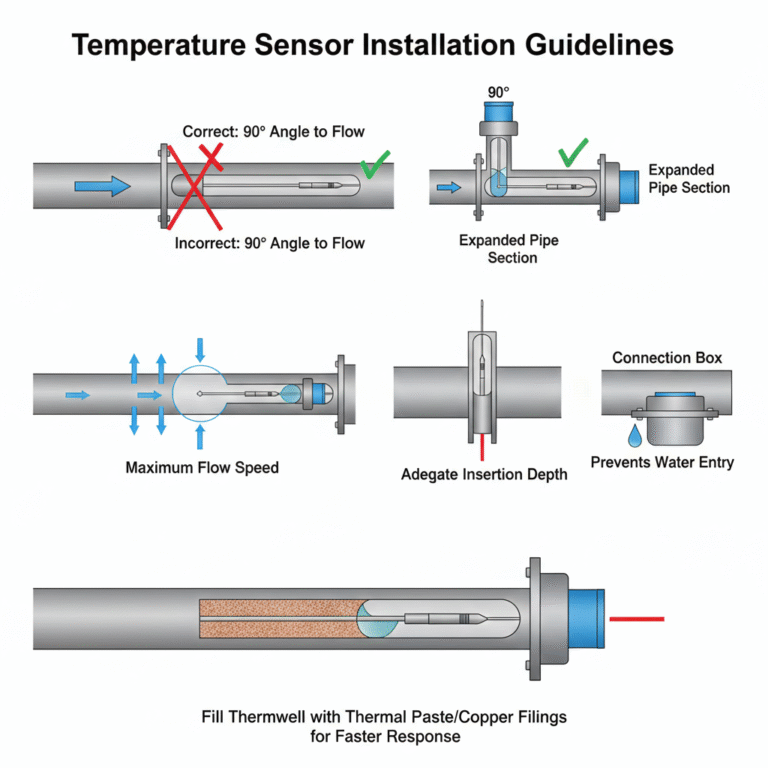

Proper installation of temperature sensors is crucial to ensure measurement accuracy. Here are some key installation requirements:

When installing temperature sensors on pipelines, ensure that the sensor is fully exposed to the medium being measured. The sensor should be positioned at a 90° angle to the flow direction, and should not align with the flow direction.

For pipelines with diameters smaller than 50mm (for thermometers) or 80mm (for RTDs or bimetallic thermometers), install the temperature sensors on an expanded pipe.

The working end of the temperature sensor should be positioned at the location of the maximum flow speed in the pipeline.

Ensure the sensor has adequate insertion depth to reduce measurement errors.

Position the sensor’s connection box with the cover facing downward to prevent water or liquid from entering.

To reduce response lag, it is advisable to fill the protective casing between the sensor and the casing with materials like transformer oil or copper filings for better thermal conductivity.

5. Types of Sensor Mounting Methods and Their Applications

Temperature sensors are typically installed using two mounting methods: screw-type fittings and flanged fittings.

Screw-type Mounting: Suitable for installing sensors on pipes carrying non-corrosive media. This method is compact and space-efficient.

Flanged Mounting: Ideal for installing sensors on equipment in high-temperature, corrosive, or hazardous media. This method is easier to maintain and is suitable for measuring temperature in catalytic layers or environments with solid particulate matter.