Introduction

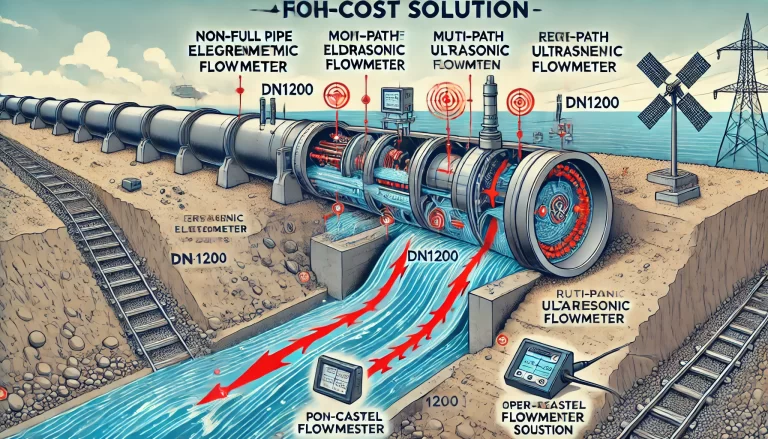

Non-full pipe flow measurement is a notorious challenge in various industries such as municipal wastewater management, agricultural irrigation, and industrial processes. The complexity increases significantly when dealing with large-diameter pipelines (DN800 and above), slight positive pressures, and slurry conditions. Selecting an unsuitable measurement method can lead to inaccurate readings, high maintenance costs, and operational inefficiencies.

Based on 15 years of field experience, this article provides an in-depth practical comparison of four major solutions, their advantages, limitations, and optimal application scenarios.

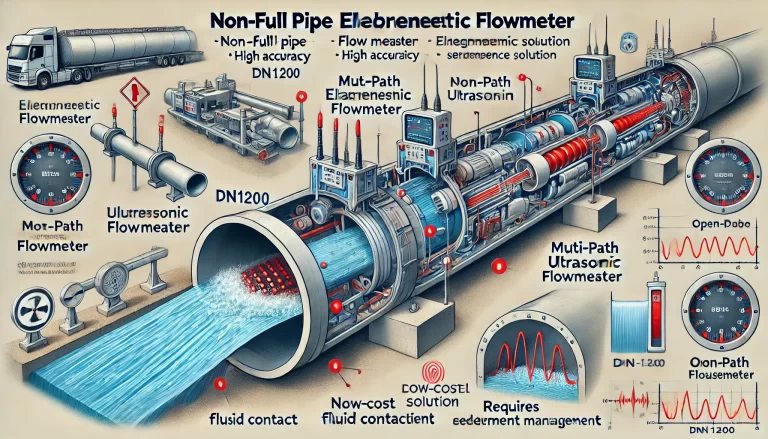

Solution 1: Non-Full Pipe Electromagnetic Flowmeter – High-Precision Premium Option

Technology Overview:

Utilizes customized electrodes and special linings to accommodate fluctuating liquid levels.

Offers a precision of up to ±2%, making it highly reliable.

Designed to resist interference from slurry and sedimentation.

Pros:

✅ High accuracy (±2%) ✅ Strong anti-interference capability against sludge buildup ✅ Suitable for demanding industrial environments, such as petrochemical applications

Cons:

❌ High cost – a DN1200 model costs over $40,000 ❌ Maintenance complexity – requires pipeline drainage for servicing

Best Application Scenarios:

✔️ High-precision measurement requirements ✔️ Petrochemical and high-pressure industrial fluids ✔️ Permanent installations with high budgets

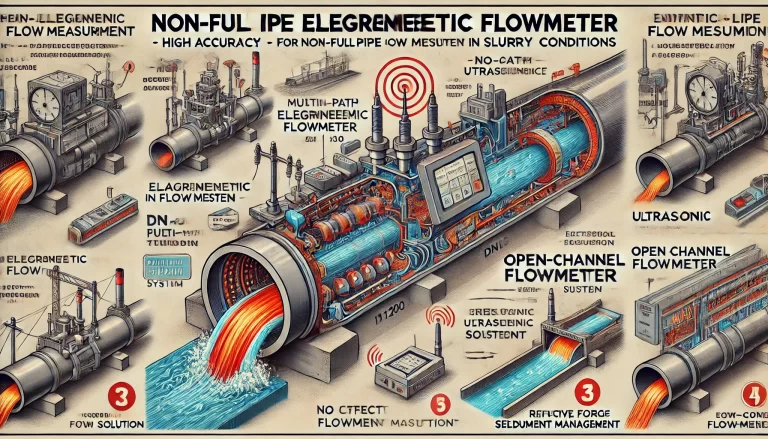

Solution 2: Multi-Path Ultrasonic Flowmeter – High-Tech Choice for Large Pipelines

Technology Overview:

Employs 4 to 8 transducer arrays with advanced acoustic velocity compensation.

Works through non-contact measurement, reducing wear and tear.

Becomes increasingly cost-effective for DN2000 and larger pipelines.

Pros:

✅ Non-invasive, easy to install without modifying pipes ✅ Effective for large-diameter pipelines (DN2000+) ✅ No direct contact with the fluid, no risk of corrosion or contamination

Cons:

❌ Sludge accumulation over 10 cm leads to signal attenuation ❌ Requires periodic cleaning and transducer calibration ❌ Expensive for smaller pipeline diameters

Real-World Example:

A municipal wastewater plant with DN1800 discharge pipes used this system but faced annual maintenance costs amounting to 15% of the device price due to sediment buildup.

Best Application Scenarios:

✔️ Large-diameter pipelines (DN2000+) ✔️ Applications where pipe modifications are impractical ✔️ Clean or mildly contaminated fluids with minimal sedimentation

Solution 3: Open Channel Flowmeter System – The Most Cost-Effective Option

Technology Overview:

Combination of a Parshall flume and an ultrasonic level sensor.

Provides a highly economical flow measurement method with reliable performance.

Cost and Implementation Considerations:

💰 Total system cost for DN1500: Under $7,000 💰 Annual calibration and maintenance costs: Minimal

Pros:

✅ Most budget-friendly solution ✅ Works well for temporary or cost-sensitive projects ✅ Easy maintenance with no need for pipeline modifications

Implementation Challenges:

❌ Requires a 1:100 slope for proper flow dynamics ❌ Upstream debris filtering (grate installation) is necessary ❌ Accuracy affected by sediment accumulation and level sensor calibration

Performance Data:

A municipal drainage project using this setup for three years achieved an annual average error of ±5%, demonstrating strong reliability with proper maintenance.

Best Application Scenarios:

✔️ Temporary or cost-sensitive monitoring projects ✔️ Municipal and agricultural water management ✔️ Situations where a minor loss of accuracy is acceptable

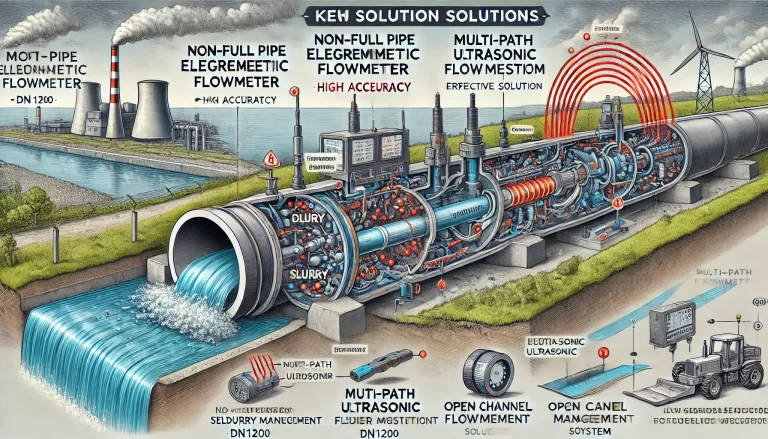

Solution 4: Engineering Modifications – Long-Term Investment Strategy

Optimization Approaches:

Adding a U-bend to induce a siphon effect, ensuring full pipe conditions

Installing a vacuum-breaking valve to prevent cavitation

Raising pipeline segments to facilitate natural flow direction

Cost and Savings Analysis:

💰 DN1000 modification cost: Approximately $10,000 💰 Potential savings: Enables the use of standard electromagnetic flowmeters, reducing costs by $20,000+

Real-World Example:

A chemical plant upgraded its circulation water measurement system using this method, leading to $170,000 in annual savings on chemical costs due to improved accuracy.

Best Application Scenarios:

✔️ Long-term projects with operation periods exceeding 3 years ✔️ Situations where precise flow measurement is crucial ✔️ Industrial environments with high operational efficiency goals

Golden Selection Principles: Which Option Should You Choose?

✅ For short-term projects: Open channel systems are the best due to their affordability and ease of implementation. ✅ For long-term operation (>3 years): Engineering modifications should be prioritized for accuracy and cost-effectiveness. ✅ For large-diameter pipelines (>DN2000): Multi-path ultrasonic flowmeters become the most viable due to their scalability. ✅ For high-budget industrial applications: Non-full pipe electromagnetic flowmeters deliver unmatched precision.

Key Takeaways:

There is no one-size-fits-all solution for non-full pipe flow measurement.

Municipal projects (~80% of cases) can achieve sufficient accuracy with open-channel solutions, provided proper maintenance is in place.

Engineering modifications require higher upfront investment but offer the ultimate long-term solution.

By carefully assessing budget, operational conditions, accuracy requirements, and maintenance capabilities, you can select the most cost-effective and reliable flow measurement solution for your specific needs.