How they work

Until comparatively recently liquids being sold had to be measured by hand, using standard containers. Older readers will probably remember the days when a milkman who was asked for three pints would fill and empty a one-pint measure three times in succession. The first liquid quantity meters were the outcome of an attempt to mechanize this technique and thus turn it into an automatic, continuous process.

Such meters are usually known as positive displacement meters, although there is a tendency nowadays to drop the word “positive” and call them displacement meters. In principle, they all have the same mode of operation, in that they separate the flowing stream into a series of discrete “pockets” of liquid and then count the pockets. However, in practice, they achieve this end by a remarkable variety of means.

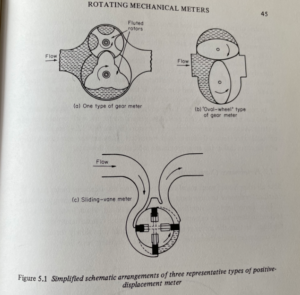

By way of example, three different types-a two-rotor gear meter, an oval wheel meter, and a sliding-vane meter-are illustrated diagrammatically in Figure 5.1. Many other types are in use, including three-rotor gear meters, multiple piston meters, ring piston meters, and nutating-disc meters. They are all quite complex mechanisms, and it is beyond the scope of this book to describe their construction in detail.

These are all examples of high-quality positive displacement meters, which are expensive products of precision engineering with high accuracy. Their main use is for metering expensive liquids such as fuels and oils for the purpose of sale, although they are also used for many other purposes. There are other, cheaper, types of meter employing the positive displacement principle which is used for less exacting duties such as domestic water metering; they are dealt with in section 5.6. The present section is concerned solely with the high-quality types, for which the term”positive displacement meter” is often reserved.

These highly engineered positive displacement meters are very nearly true to their name: the total volume of liquid displaced in one revolution of the meter is almost constant over a fairly wide range of flowrate, viscosity, pressure, and temperature so that the total number of revolutions of the meter provides a reasonably direct, or “positive” measure of the total volume passed.

The big problem in designing any kind of positive displacement meter is to achieve good sealing of the moving parts without creating an unacceptable friction torque. The result is usually a compromise-a meter with a moderate amount of friction torque and a moderate amount of liquid “slip” through the meter. For this reason, every positive displacement meter needs to be calibrated at several flow rates over the range within which it is to be used, with a liquid of appropriate viscosity.

Most positive displacement meters are fitted with a totalizing dial, reading directly in liters or gallons. The readout mechanism often includes an adjusting device, so that if on calibration, the meter is found to be over-reading or under-reading, it can be reset to read correctly. If the meter is subject to legal control, this device will generally be sealed by the official inspector.

In addition to the usual dial for visual reading, some positive displacement meters can be fitted with electrical pulse generators are another optional extra frequently found on these meters. They are also sometimes fitted with an extra dial giving an approximate indication of flow rate.

Performance characteristics

Like all complicated mechanical devices, a positive displacement meter has a frictional resistance to movement, and it takes a fair amount of energy to rotate it. This energy has to be supplied by the flowing liquid, which loses quite a lot of its head in doing so. At extremely low flow rates there is

insufficient energy in the liquid to turn the meter at all; instead, the liquid slips slowly through the fine clearances inside the meter, while the meter registers zero flow.

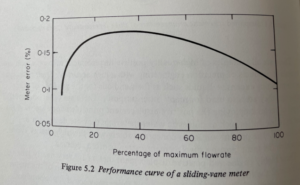

Nevertheless, in a well-designed meter, slip is not a serious problem at flow rates within the normal working range. A performance curve for a vane-type meter tested at NEL is given in Figure 5.2, where the great increase in a slip at a low flow rate accounts for the rapid change in meter error within this region.

Despite this, the meter still has a rangeability of about 20:1, with linearity of ±0.05% and an accuracy(when newly calibrated) of ±0.2% of volume over this range- a performance that cannot be matched by any flowmeters outside the positive displacement family. (Nor can it easily be equaled by other positive displacement meters; this particular type of meter is at, or very near, the top of its class.)

In general, positive displacement meters perform best when in the medium size range, that is to say, when designed for a maximum flow rate between about 2 and about 50 liters per second. Design limitations make it difficult to achieve high performance in either very small or very large positive meters.

At present, the only way to obtain high performance from very small positive displacement meters is to fit them with a drive mechanism powered by an external servo-controlled motor. In this way, friction is practically eliminated, slip is minimized, and wide rangeability is obtained. These highly sophisticated devices, however, are extremely expensive.

Advantages

(a) High-quality positive displacement meters will measure total liquid volume with high accuracy over a wide range of flow rates and are very reliable over long periods. (For these reasons they are used exclusively in such applications as filling-station petrol pumps.) (b) They will meter moderately viscous liquids accurately as long as they are calibrated with the right liquid, and in some models, the dials can be adjusted to read correctly with the liquid concerned. (C) The direct dial readout makes for simplicity of operation, enabling them to be used by unskilled operators. (d) They are not affected by upstream flow disturbances, and so can be installed very close to a bend without loss of accuracy.

Disadvantages

(a) They are bulky. especially in the larger sizes.

(b) They have a high head loss (through not quite so high as is often supposed)

(c) They are viscosity sensitive -but to a lesser extent than many other types of meter.

(d) They can be damaged by dirt particles, and filtration of the inflowing liquid is therefore usually necessary.

(e) The more accurate types are rather expensive.

(f) If they should seize up (a rare occurrence) they completely block the flow.

(g) They are suitable over only a limited range of pressure and temperature.

(h) Some types will introduce pulsations into the flow.

Points to watch when buying and using

(a) Because there are so many different designs on the market, different manufacturer’s products vary quite widely in performance. If you need good performance, it is well worthwhile obtaining certified performance curves from several suppliers for comparison, before deciding which meter to buy.

(b) These meters will normally work with the flow traveling in one direction only. Consequently, they are generally supplied with a choice of “left-hand” or “right-handed” dials. But there is no need to be dismayed if you have one with the dial facing in an inconvenient direction because it is usually not difficult to remove the measuring head and rotate it through 180°.

(c) Never use a high-quality positive displacement meter with water without first checking that the internals is made from non-corrosive materials; such meters are usually termed”water compatible”.