Introduction

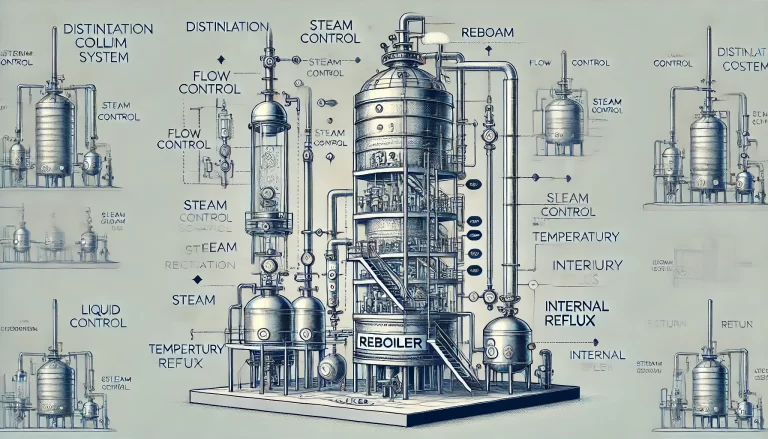

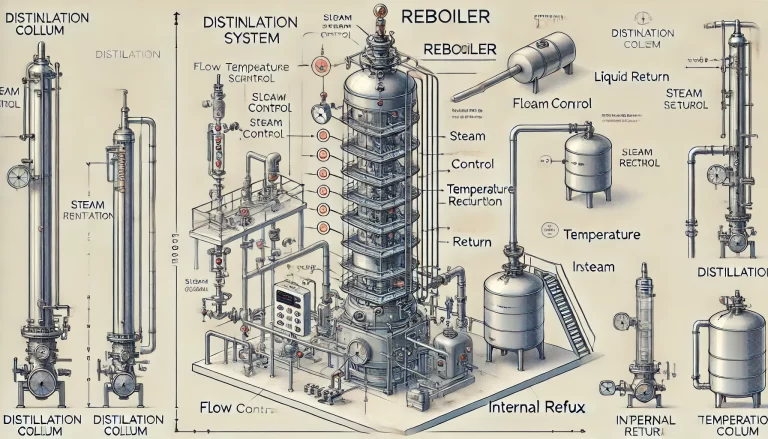

Reboilers are critical components in distillation systems, playing a vital role in maintaining the required separation performance. By understanding how to effectively utilize reboilers, engineers can optimize distillation column control schemes, ensuring stability and efficiency under various operational conditions. This article provides a comprehensive overview of reboiler usage strategies, examining both fundamental principles and practical applications.

Common Applications of Reboiler Control

1. Flow Control to Regulate Stripping Section Temperature

The most common application of reboiler flow control is to regulate the temperature in the stripping section of the distillation column. By adjusting the reboiler steam flow, the heat input can be stabilized, ensuring consistent separation performance. This method is often combined with steady-state operations to maintain simplicity and reliability.

2. Pressure Differential Control

For columns with low loads but requiring high separation precision, reboiler steam flow can be utilized to control the column’s pressure differential. This approach is particularly useful when feed loads fluctuate significantly, as it prioritizes stable vapor-liquid traffic over energy efficiency.

3. Internal Reflux Control

In scenarios where the overhead reflux manages the rectifying section temperature or the reflux drum level, reboiler flow can be used to control internal reflux. This ensures steady vapor-liquid traffic within the column. For light-component stripping towers where non-condensable gases are vented, controlling internal reflux with the reboiler is often more effective than managing bottom temperature.

4. Reboiler Outlet Temperature Control

In some cases, controlling the outlet temperature of the reboiler itself is advantageous. For example, when the reboiler functions as a fired heater, this control scheme resembles the temperature cascade control in reactors, with the primary loop requiring further analysis to determine its necessity.

Specialized Applications

1. Bottoms Level Control with Steam Flow

When bottom-product withdrawal rates are low or fixed, reboiler steam flow can be used to manage the liquid level in the reboiler sump. For instance, in perchloroethylene production columns, advanced control systems use this method to stabilize the sump level while maintaining the fixed withdrawal rate. This strategy requires integration with the overall control system to avoid design and implementation challenges.

2. Reflux Drum Level or Top Pressure Control

In certain configurations, reboilers can be utilized to control the reflux drum level or column top pressure. These strategies are situational and require careful consideration of the available degrees of freedom in the system.

Key Principles for Effective Control

Balancing Manipulated Variables

Reboiler steam flow, reflux ratio, and bottom product withdrawal are the main manipulated variables. At least two are required to stabilize the liquid levels at both ends of the column. For instance, if the top product is gas-phase and used for pressure control, it consumes one degree of freedom, leaving fewer options for optimizing heat input and temperature.

Load Considerations

Large, stable-load columns offer greater energy-saving potential. Conversely, low-load, fluctuating columns prioritize maintaining separation performance, often at the expense of energy efficiency.

Minimizing Over-Distillation

While over-distillation is a common issue, it is often necessary to counteract disturbances. Continuous refinement of operating experience can reduce its occurrence without compromising performance.

Advanced Control Approaches

Integration with Modern Automation Systems

Leveraging digital tools such as advanced process control (APC) and distributed control systems (DCS) can enhance the precision of reboiler operations.

Examples include automated feedback loops for real-time adjustment of steam flow and algorithms for optimizing reflux ratios based on feed composition changes.

Utilizing First-Principle Models

Control schemes based on first-principle models ensure that changes are both theoretically sound and practically feasible. Key considerations include material and energy balances, as well as system dynamics.

Conclusion

Effective utilization of reboilers in distillation columns hinges on a deep understanding of operational principles and adaptability to specific conditions. By balancing simplicity with advanced control methodologies, engineers can achieve optimal performance, whether the goal is energy efficiency or separation precision. Adhering to the principles of minimalism and robustness ensures that distillation systems remain resilient and efficient under varying operational demands.