When working in hazardous areas, selecting the correct explosion-protection method is critical for safety and compliance. Among these, Zone 0 environments—where explosive atmospheres are present continuously or for long periods—are the most demanding. Many engineers automatically think of intrinsically safe (Ex ia) instruments for Zone 0, but is that the only option? The answer is: not entirely.

Understanding Zone 0

According to IEC 60079 and GB/T 3836 standards, Zone 0 is defined as an area where an explosive gas atmosphere is present continuously, for long periods, or frequently. Examples include:

Inside fuel storage tanks

Gas pipelines containing flammable vapors

The vapor space above volatile liquids in confined vessels

The protection method for any device placed in Zone 0 must ensure zero ignition risk under all operating and fault conditions.

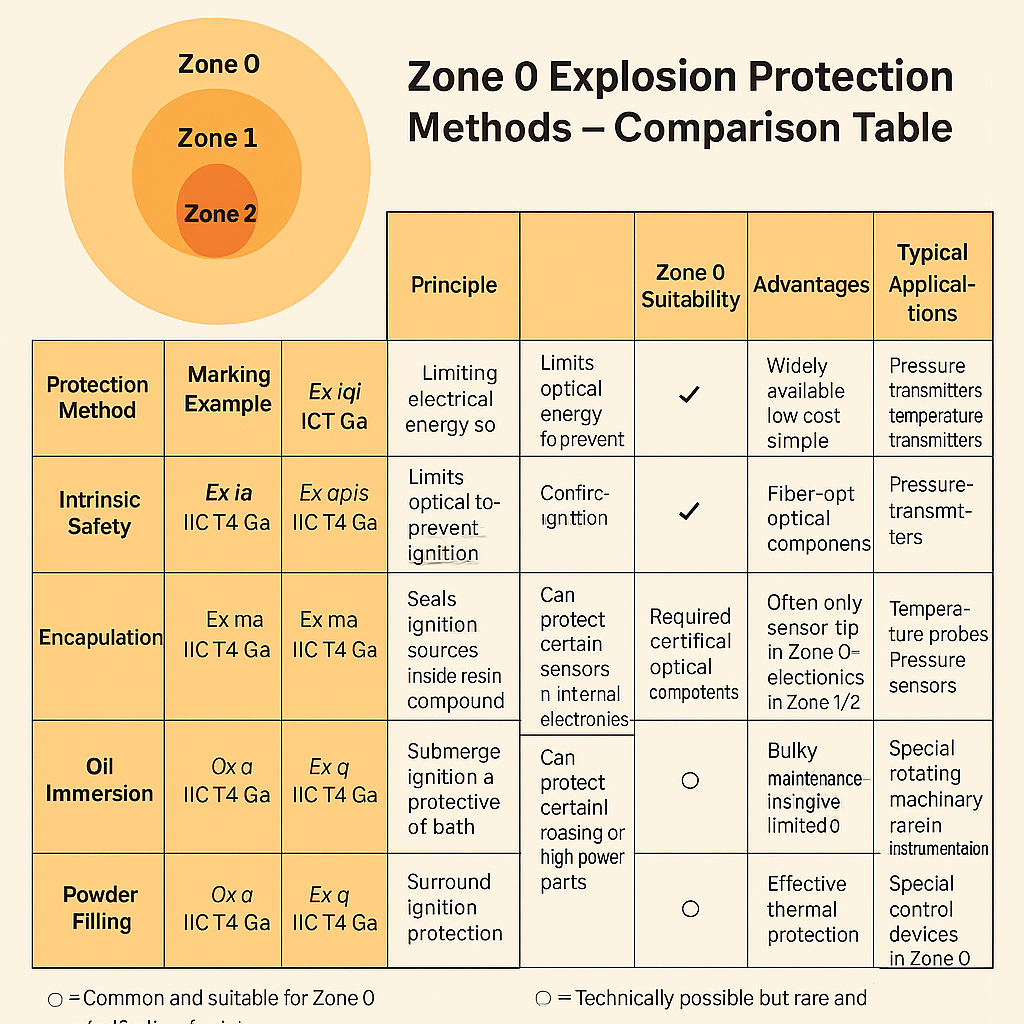

Explosion Protection Methods for Zone 0

1. Intrinsic Safety – Ex ia

This is by far the most common and practical solution for Zone 0.

Principle: Limit the electrical energy in the circuit so that sparks or thermal effects cannot ignite an explosive atmosphere.

Requirement: Must remain safe under normal operation, a single fault, and any two independent faults.

Advantages:

Simple installation and maintenance

Allows live maintenance without gas-freeing the area

Widely available for sensors, transmitters, and control equipment

2. Optical Intrinsic Safety – Ex op is

For instruments transmitting signals via optical fiber.

Principle: Limit optical power and wavelength to prevent ignition.

Application: Communication links, distributed sensing in hazardous areas.

Note: Requires certification specifically for Zone 0 optical safety.

3. Encapsulation – Ex ma

Some sensing elements can be fully encapsulated in a protective compound.

Principle: Prevents explosive gas from contacting any potential ignition source.

Limitation: Often, only the sensing tip can be in Zone 0; the electronics must be in Zone 1 or 2.

Examples: Certain temperature probes or pressure sensor elements.

4. Other Methods (Rare for Zone 0)

Protection types such as oil immersion (Ex o) or powder filling (Ex q) are technically possible but rarely used in Zone 0 because of complexity, maintenance needs, and limited certification scope.

Why Intrinsically Safe Is Usually the First Choice

Although Zone 0 standards permit a small set of other certified methods, intrinsic safety has clear advantages:

Proven track record in safety-critical applications

Easier compliance with international standards

Simplified maintenance—no need to gas-free the area for instrument work

Lower lifecycle cost compared to complex encapsulated or oil-filled designs

For most applications, Ex ia devices remain the safest, most economical, and most widely supported option.

Conclusion

No, intrinsically safe devices are not the only choice for Zone 0, but they are by far the most practical. Other certified methods—such as optical intrinsic safety or encapsulation—can also be used, but their applications are more limited, and device availability is much lower.

When in doubt, consult both the equipment certification documents and the relevant IEC or GB/T standards to confirm suitability. In hazardous area design, the goal is not only compliance but also long-term operational safety.