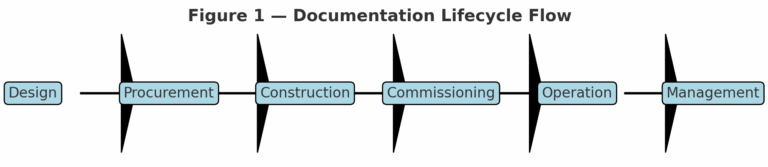

Introduction

In an instrumentation and control engineering project, the project documentation package is one of the core deliverables. It records all required documents throughout the entire lifecycle—design, procurement, installation, commissioning, and handover. A well-structured document set not only guides project execution but also ensures quality, safety, and regulatory compliance.

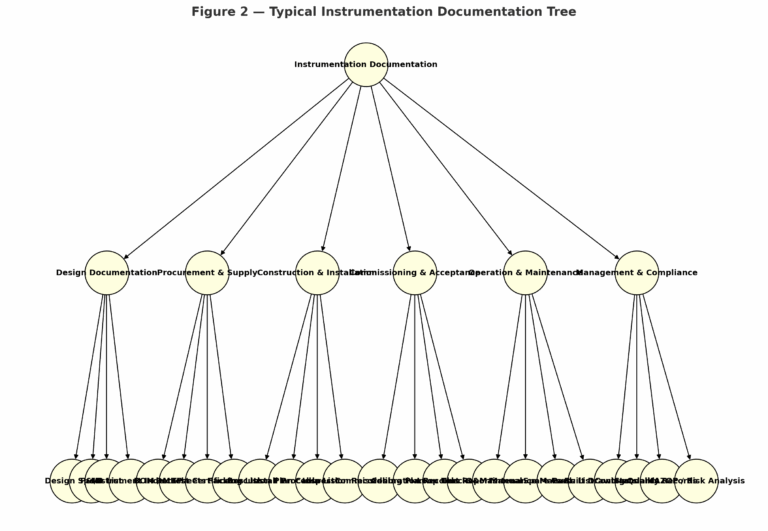

1. Design Documentation

Design documents provide the technical foundation for implementation, installation, and construction.

Overall Design Specification — Defines project objectives, scope, and technical approach.

Instrument Selection & Sizing Report — Includes measurement range, accuracy, pressure rating, materials, power supply, and signal type.

P&ID (Process & Instrumentation Diagram) — Shows process flow, instrument locations, and signal directions.

Instrument Installation & Wiring Drawings — Specifies installation method, location, and wiring connections.

Control Logic / Loop Diagrams — Used for PLC/DCS programming and interlocks.

I/O List — Complete list of all input/output signals (analog, digital).

Instrument Index — Master list of instruments (tag number, type, model, specification, manufacturer).

2. Procurement & Supply Documentation

These documents ensure that procurement and delivery comply with specifications.

Material Requisition / BOM — Lists all instruments and accessories with quantity and vendor.

Manufacturer Data Sheet & Catalogue — Product specifications and certifications.

Factory Test Certificates (CoC/CoA) — Verifies product quality before shipment.

Packing List — Reference for delivery inspection.

Certificates of Conformity & Warranty — Ensures product traceability and guarantees.

3. Construction & Installation Documentation

Used for on-site execution and quality assurance.

Construction Execution Plan — Defines workflow, schedule, and resource allocation.

Instrument Installation Procedures — Methods and safety precautions.

Cable Laying List — Cable type, length, routing, and identification.

Construction Inspection Records — Civil, mechanical, and electrical checks.

Special Process Records — Welding, explosion-proof installation, corrosion protection, etc.

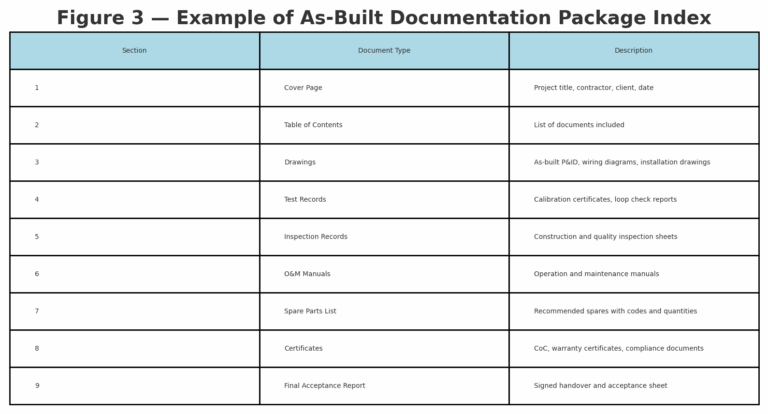

4. Commissioning & Acceptance Documentation

Guarantees system performance and compliance with design requirements.

Commissioning Plan & Schedule — Sequence for loop check, system interlock, and overall testing.

Calibration Records — For instruments such as thermometers, pressure gauges, and flowmeters.

Loop Check Sheets — Verifies continuity and signal response.

Function Test Reports — Confirms logic, alarms, and interlocks.

Commissioning Summary Report — Records issues and resolutions.

Final Acceptance Report — Jointly signed by owner, contractor, and supervisor.

5. Operation & Maintenance Documentation

Delivered to the client for long-term system operation.

Operation & Maintenance (O&M) Manual — Procedures and precautions.

Maintenance & Inspection Manual — Preventive maintenance schedules and checklists.

Spare Parts List — Recommended consumables and critical spares.

Training Materials — Operator training programs and certification records.

As-Built Drawings — Final installation drawings reflecting site modifications.

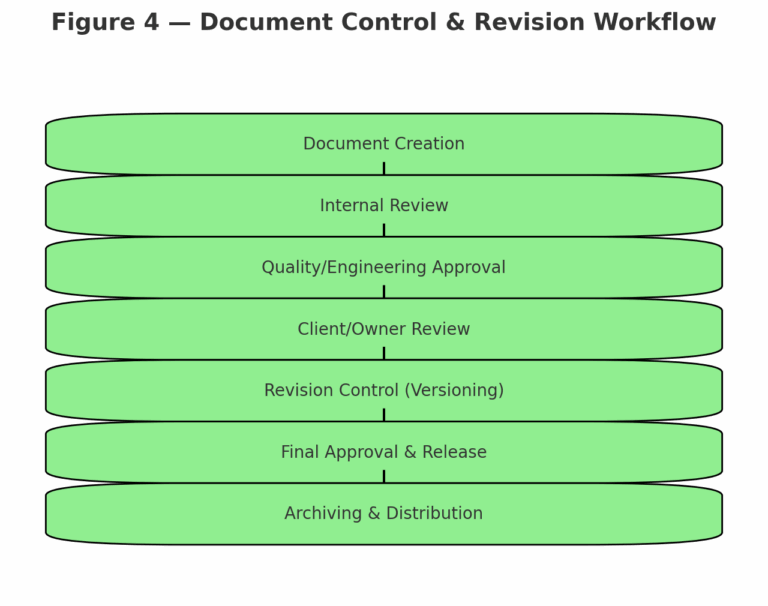

6. Management & Compliance Documentation

Ensures standardization, quality, and safety compliance.

Contracts & Technical Agreements — Formal signed documents between parties.

Standards & Code Reference List — Applicable GB/T, IEC, API, ISA standards.

Quality Management Records — ISO9001, HSE, safety inspection reports.

Risk Assessment / HAZOP Study — Safety and risk control documentation.

Project Progress & Cost Reports — Project tracking and financial control.

Document Control & Revision Records — Ensures version management and traceability.

✅ Conclusion

The Instrumentation Project Documentation Checklist consists of:

Design + Procurement + Construction + Commissioning + Operation + Management.

It is not only the technical backbone of project execution but also the foundation for quality assurance, safety, and compliance throughout the project lifecycle.