In industrial production, temperature sensors for monitoring furnace temperatures up to 1200 °C are critical for maintaining process stability and ensuring product quality. This article provides a detailed overview from four aspects: sensor types, working principles, key features, and application considerations.

1. Applicable Sensor Types

For high-temperature measurement up to 1200 °C, the following types of industrial furnace temperature sensors are commonly used:

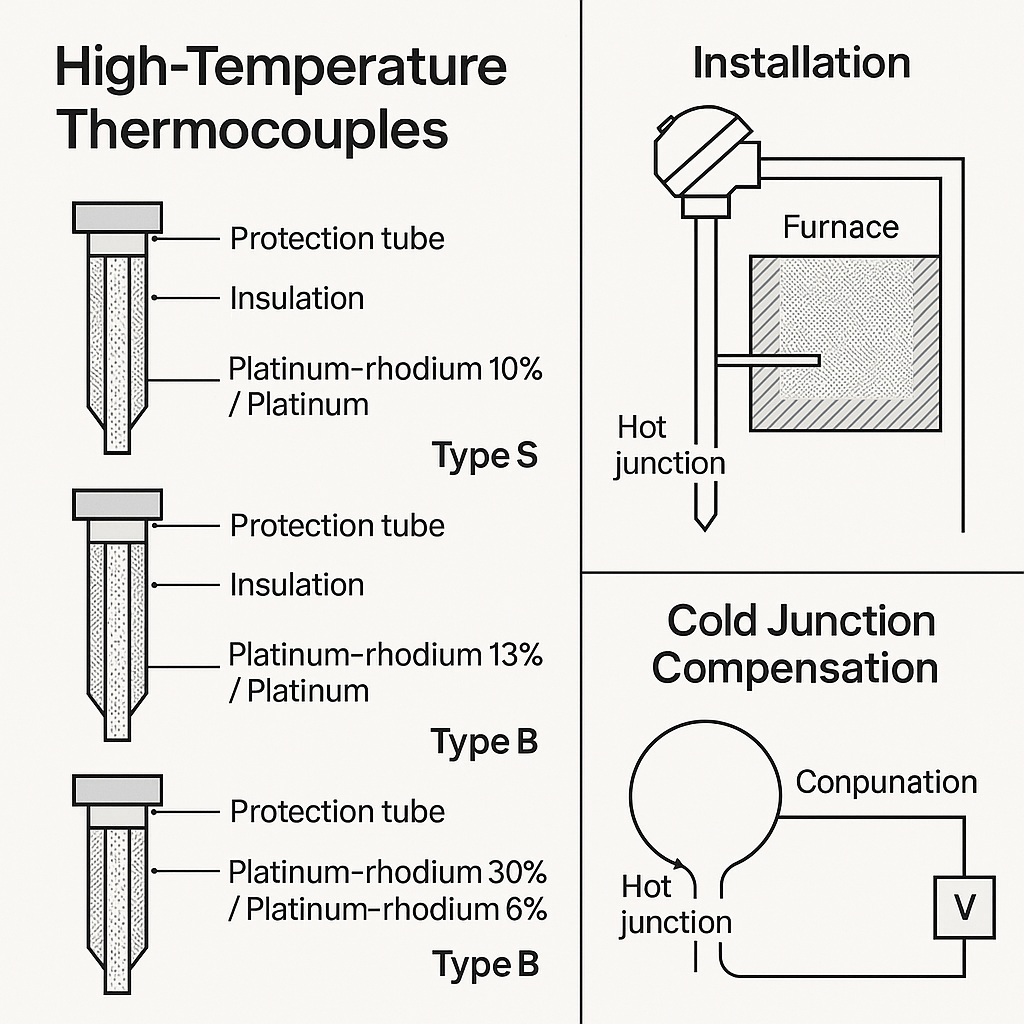

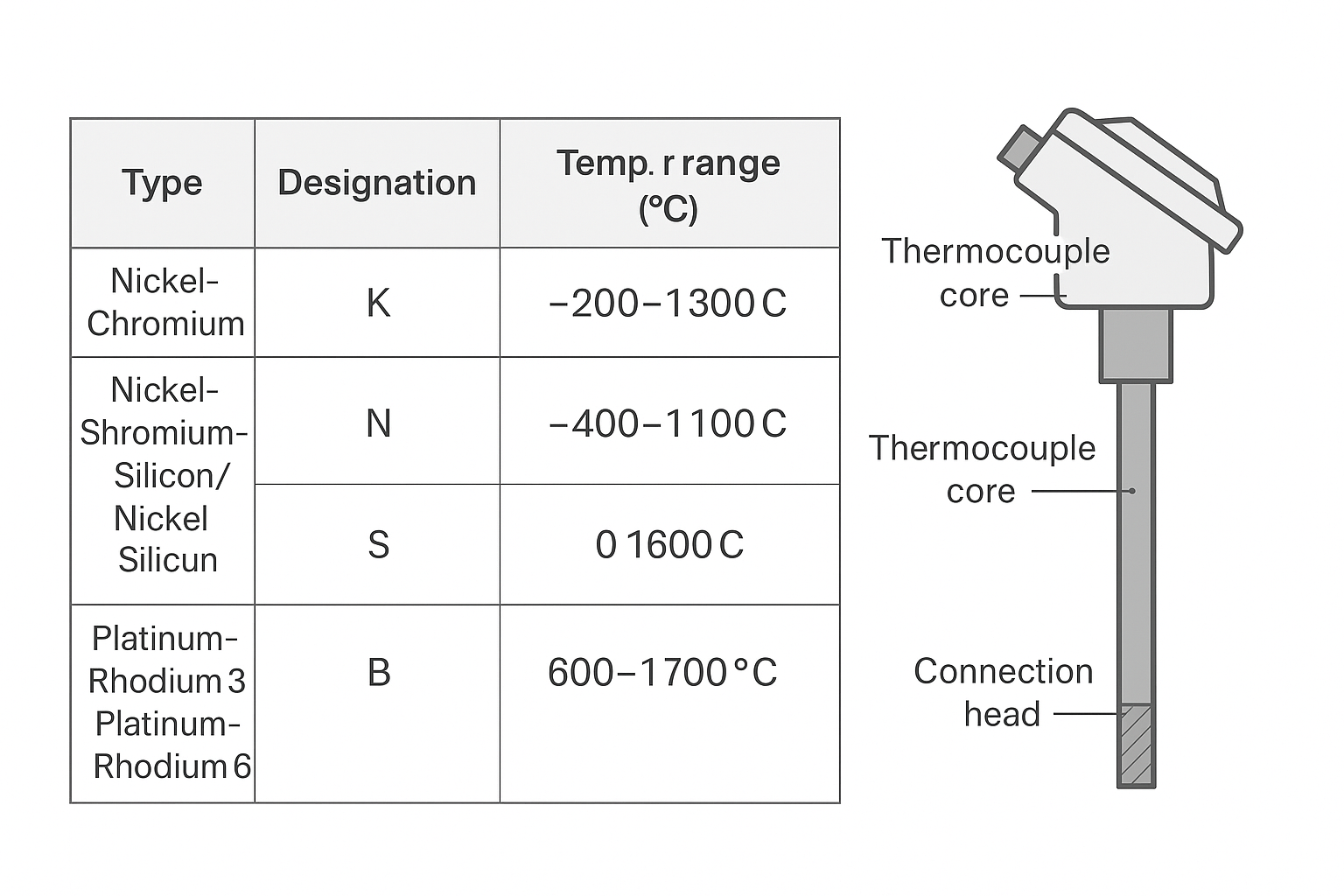

Thermocouples

The most widely used high-temperature measurement technology in industry.

Type S (Platinum-Rhodium 10% / Platinum)

Temperature range: 0–1600 °C

Stable long-term operation around 1300 °C

Fully meets the 1200 °C furnace monitoring requirement

Type R (Platinum-Rhodium 13% / Platinum)

Similar performance to Type S

Slightly better high-temperature stability

Type B (Platinum-Rhodium 30% / Platinum-Rhodium 6%)

Temperature range: 600–1800 °C

Excellent accuracy at 1200 °C

Strong corrosion resistance for harsh furnace environments

Resistance Temperature Detectors (RTDs)

Standard RTDs (e.g., Pt100) have an upper limit of 400–600 °C

Special high-temperature RTDs can exceed 1000 °C

Rarely used at 1200 °C except as supplementary or low-range measurement

2. Working Principle

Taking thermocouples as the main example:

They operate based on the Seebeck effect — when two different conductive materials form a closed loop with two junctions (hot and cold ends), a voltage is generated proportional to the temperature difference. By measuring this thermoelectric voltage and knowing the cold junction temperature, the hot junction temperature inside the furnace can be calculated.

3. Key Features of High-Temperature Sensors

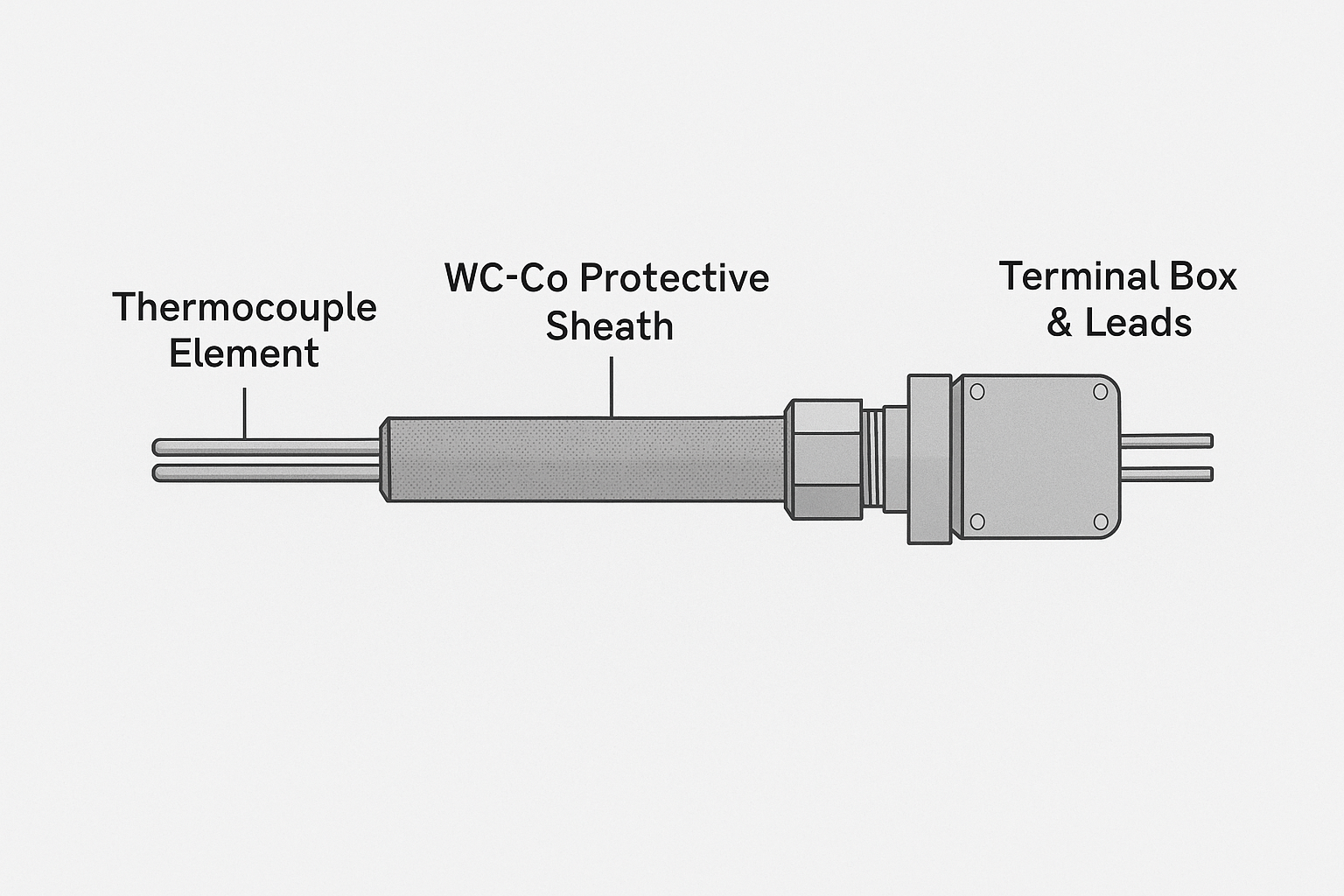

High-Temperature Resistance

Sensing elements and protection tubes must use refractory materials (e.g., alumina, platinum-rhodium alloys) to ensure long-term stability at 1200 °C without degradation.

Fast Response

Achieved by optimizing element structure (e.g., reduced diameter) and using slotted or perforated protection tubes to minimize thermal lag.

Measurement Accuracy

Noble metal thermocouples (S, R types) can reach ±1 °C or ±0.5% t (t = measured temperature), meeting furnace control requirements.

Interference Resistance

Sensors must withstand electromagnetic interference, dust, and corrosive gases through shielding design and corrosion-resistant protection tubes.

4. Application Considerations

Installation Position

Place sensors in zones with uniform temperature that reflect true process conditions. Avoid hot air inlets, cold air leaks, or dead zones. Ensure the sensing element is fully in the high-temperature zone.

Cold Junction Compensation

Thermocouple cold junction temperature affects measurement accuracy. Use built-in compensation methods (e.g., thermostatic chambers or electronic compensation) to minimize errors.

Regular Calibration

Sensor characteristics may drift over time. Calibrate every 6–12 months according to standards to maintain accuracy.

Maintenance

Clean accumulated dust or oxide scale, inspect the protection tube for cracks, and replace aged or damaged components promptly.

Conclusion:

By selecting the right high-temperature sensor type and combining it with proper installation, calibration, and maintenance practices, industrial furnaces can achieve accurate, real-time monitoring at 1200 °C, ensuring stable operation and consistent product quality.