Introduction

Hydrogen (H₂) and nitrogen (N₂) are two of the most important industrial gases, widely used in industries ranging from chemical synthesis and metallurgy to energy and electronics. Monitoring their purity and mixture ratios is crucial for process efficiency, safety, and product quality.

In practice, users often face a choice: should they use a single gas purity analyzer (for pure hydrogen or nitrogen), or a mixed gas analyzer (for specific H₂/N₂ combinations)? This article explains the differences, highlights typical applications, and helps engineers and procurement managers make the right decision.

Single Gas Purity Analyzers

A single gas purity analyzer is dedicated to monitoring one gas, such as hydrogen or nitrogen.

Key Features

High-precision calibration with standard pure gas (99.999%VOL).

Exclusive application for a single gas type.

Measurement range: 0–99.999%VOL with 0.001%VOL resolution.

Fast response: ≤10 seconds with pump-suction sampling.

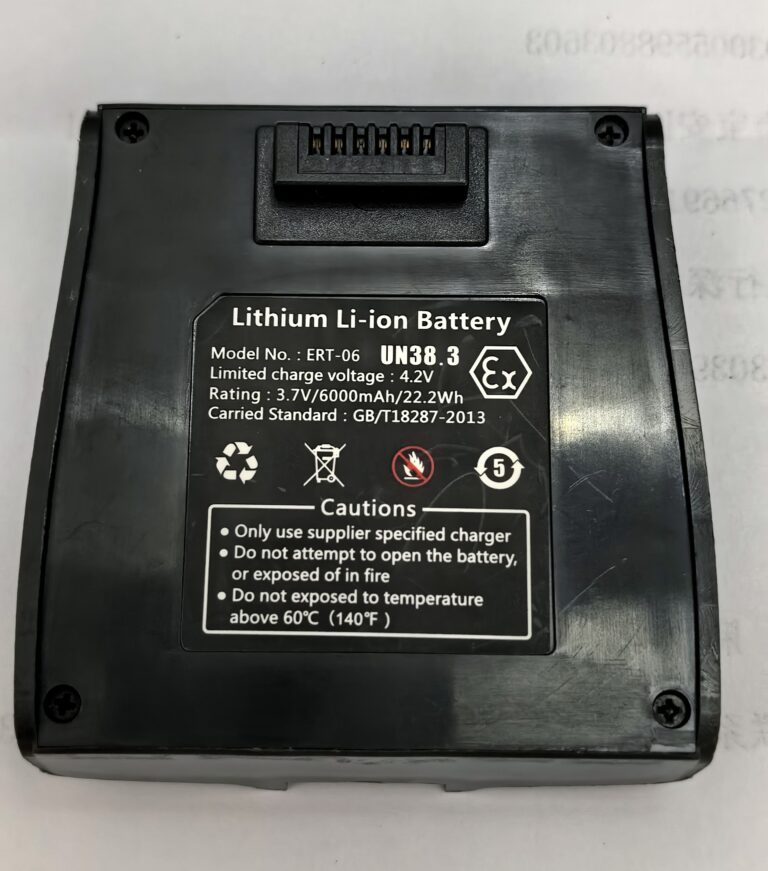

Portable and robust design with rechargeable battery and data storage.

Hydrogen Purity Analyzer Applications

Ammonia synthesis: Hydrogen purity must be tightly controlled in H₂/N₂ feedstock.

Hydrogen fuel cells: Even ppm-level impurities can damage catalysts.

Electrolyzers and hydrogen generators: Monitoring output quality ensures reliable supply.

Steelmaking: Hydrogen is increasingly used as a reducing agent for greener steel production.

Nitrogen Purity Analyzer Applications

Food packaging: High-purity nitrogen prevents oxidation and extends shelf life.

Semiconductor industry: Ultra-pure nitrogen prevents contamination during chip fabrication.

Pharmaceuticals: Nitrogen is used as a protective atmosphere in sensitive production.

Inerting systems: Nitrogen displaces oxygen to reduce explosion risks in chemical plants.

By focusing on one gas, these analyzers offer maximum stability, accuracy, and long-term reliability.

Mixed Gas Analyzers (H₂/N₂ Combinations)

In many chemical processes, hydrogen and nitrogen are not used separately but as a fixed-ratio mixture. For example, ammonia production requires a feedstock of 75% H₂ and 25% N₂.

Key Features

Calibrated with standard mixed gas (e.g., H₂:N₂ = 75:25).

Direct hydrogen measurement, with nitrogen automatically calculated as the balance.

Customizable calibration: Users can specify other ratios (e.g., 60:40), but the analyzer must be factory-calibrated for that exact ratio.

Fast response and portable design with pump-suction sampling.

Application Examples

Ammonia plants: Ensuring the correct H₂/N₂ ratio is essential for catalyst performance.

Fertilizer production: Mixture ratio affects yield and energy efficiency.

Specialty chemicals: Precise gas blending is required for synthesis processes.

Important Note: If the analyzer is calibrated for 75:25 but used on a 60:40 mixture, results will not be accurate. Calibration must match the process gas ratio.

Comparison: Single Gas vs. Mixed Gas Analyzers

| Aspect | Single Gas Analyzer (H₂ or N₂) | Mixed Gas Analyzer (H₂/N₂) |

|---|---|---|

| Calibration | Pure gas (99.999%) | Specific H₂/N₂ ratio (e.g., 75:25) |

| Accuracy | High, independent measurement | Accurate only for calibrated ratio |

| Flexibility | Measures one gas only | Measures mixture composition |

| Applications | Hydrogen fuel cells, food packaging, semiconductors | Ammonia production, fertilizer, chemical synthesis |

| Typical Users | Gas suppliers, R&D labs, manufacturers | Chemical plants, fertilizer factories |

Can They Be Integrated?

Some users wonder whether a single device can handle both pure gas and mixtures. In practice, the answer is no—because the calibration and sensor configuration are different.

However, modern portable analyzers can be configured with interchangeable sensors, allowing users to deploy one platform with different calibration modules. Many factories choose to combine both solutions:

A hydrogen purity analyzer for monitoring electrolyzer output.

A nitrogen purity analyzer for monitoring nitrogen generator quality.

A mixed gas analyzer for ensuring the correct H₂/N₂ ratio in synthesis.

Together, these devices provide a comprehensive monitoring system.

Conclusion

The choice between a single gas purity analyzer and a mixed gas analyzer depends on your application:

Choose a single gas analyzer if you need ultra-high purity H₂ or N₂ monitoring.

Choose a mixed gas analyzer if you must verify a specific H₂/N₂ ratio.

For plants that require both, the best strategy is to combine both solutions to ensure full coverage of quality control.

With the right analyzer, industries can achieve greater efficiency, safer operations, and higher product quality.