Flow meters are essential in industries such as chemical, light manufacturing, heavy industries, energy, agriculture, and environmental protection, all of which rely on liquid flow measurement. Among the various types of flow meters, some are suitable for measuring water, including electromagnetic, turbine, vortex, orifice plate, ultrasonic, and gear flow meters. However, the choice of flow meter varies depending on the characteristics of the liquid and the specific needs of each industry. For example, water treatment plants often deal with wastewater, effluent, and other complex liquids with varying pH levels, corrosiveness, and temperature, which require careful selection of the appropriate flow meter. Below is a guide on how to choose the best flow meter based on the liquid’s properties.

1. Choosing a Flow Meter for Electroplating Wastewater and Chemical Wastewater

Recommended Flow Meters: Electromagnetic Flow Meter or Ultrasonic Flow Meter

- Electromagnetic Flow Meters: These flow meters are highly accurate and stable, with no moving parts. They are widely used in water treatment plants, water distribution, and environmental applications. Electromagnetic flow meters are ideal for complex liquids like electroplating wastewater and chemical effluents. The reason for this is that electromagnetic flow meters can be customized with specific sensor linings and electrode materials to match the liquid’s corrosiveness, abrasiveness, and temperature. For example, titanium (Ti), tantalum (Ta), or platinum (Pt) electrodes can be selected for highly corrosive liquids. Additionally, electromagnetic flow meters are immune to wear, clogging, and are highly effective in measuring slurry or liquids with solid particles, such as mineral slurries and pulp.

However, electromagnetic flow meters are not suitable for measuring liquids with low electrical conductivity, such as oils, deionized water, and lubricating oils.

- Ultrasonic Flow Meters: These meters also measure conductive liquids but cannot handle strong acids or alkalis. The advantage of ultrasonic flow meters is their ease of installation, especially in sites where pipes are already laid out. They require no disruption to the existing pipeline and can be installed without cutting the pipe. Ultrasonic meters are especially suitable for large diameter pipes and can use multiple probes for point measurements as needed.

2. Choosing a Flow Meter for High Purity Water, Deionized Water, and Sugar Solutions

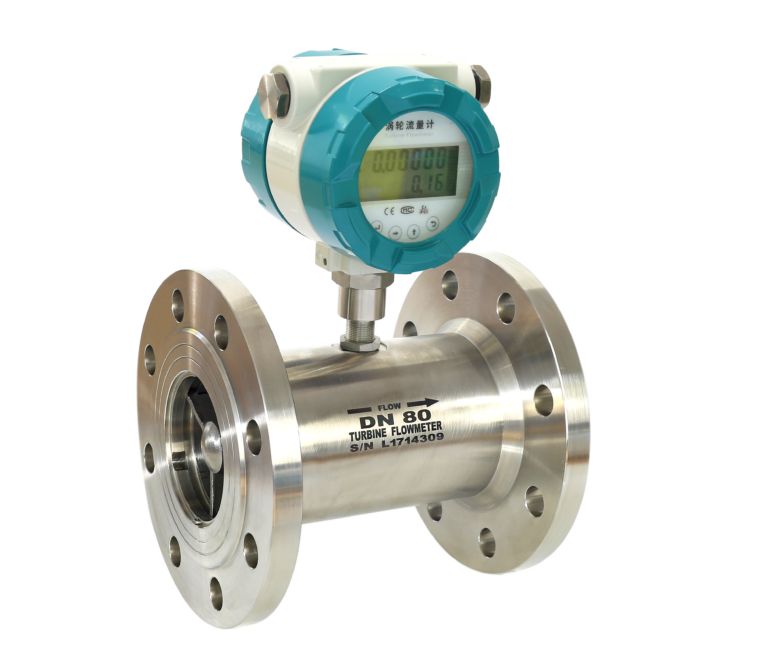

Recommended Flow Meter: Turbine Flow Meter

Turbine flow meters are particularly well-suited for measuring clean liquids, such as high-purity water, organic liquids, oils, and low-viscosity liquids. These meters have a compact and lightweight design, and they are easy to install and maintain. However, turbine flow meters require a high level of cleanliness in the fluid being measured, which makes them unsuitable for liquids with high concentrations, corrosive properties, or large amounts of solid particles.

Turbine meters are frequently used for applications such as measuring water flow in the food and beverage industry, where the liquid is clean and the flow is steady.

3. Choosing a Flow Meter for High Viscosity Liquids

Recommended Flow Meter: Gear Flow Meter

Gear flow meters are positive displacement meters ideal for both low and high-viscosity liquids. These meters use a unique design that makes them highly accurate for measuring thick fluids like glue, heavy oil, tar, resin, syrup, yogurt, and toothpaste. The gear design can be customized with materials like PTFE (Teflon) for better resistance to corrosion, which is particularly useful for highly corrosive liquids. Gear flow meters are known for their high repeatability, precision, and reliability, making them an excellent choice for industries like fine chemicals and pharmaceuticals where high viscosity fluids are common.

4. Additional Considerations for Flow Meter Selection

The selection of a flow meter goes beyond just the nature of the liquid. Other important factors include the pipe diameter, operating temperature, pressure, and the desired flow measurement range. All of these parameters need to be clearly defined to ensure the correct flow meter is selected, guaranteeing accurate and reliable flow measurement.

For instance:

- Electromagnetic flow meters are ideal for measuring conductive liquids like wastewater, effluent, and other process liquids.

- Turbine flow meters are best suited for clean liquids like lubricating oils, gasoline, and pure water.

- Gear flow meters are highly effective for measuring high-viscosity fluids, such as syrup, resin, and adhesives.

Conclusion

Choosing the right flow meter is crucial for ensuring accuracy and stability in measurement systems across various industries. By understanding the properties of the liquid being measured and considering the operating conditions such as temperature, pressure, and pipe size, you can select the most appropriate flow meter for your application. Proper selection not only ensures reliable flow measurement but also improves the efficiency and longevity of the system.