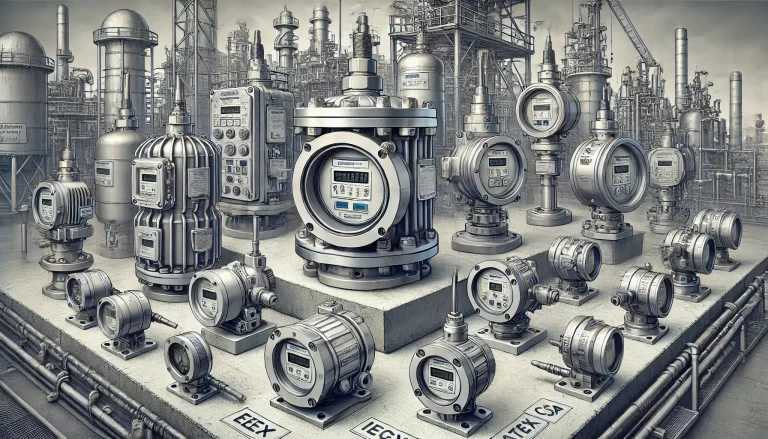

Explosion-proof instruments are specialized devices designed for use in environments where flammable gases, vapors, or dust are present, and where a potential ignition source could lead to catastrophic explosions. These instruments are essential in industries such as oil and gas, chemical processing, mining, and pharmaceuticals, where safety is a critical concern. By their design, explosion-proof instruments ensure that any internal ignition event remains contained, preventing the risk of igniting the surrounding atmosphere.

Key Features of Explosion-Proof Instruments

1. Explosion-Proof Design

The fundamental principle behind explosion-proof instruments is their ability to prevent any internal sparks, arcs, or hot surfaces from igniting the surrounding environment. This is achieved through robust enclosures that are designed to withstand an internal explosion without allowing flames or hot gases to escape. The thickness, material composition, and structure of the enclosure are critical to ensure the containment of an explosion.

- Thick-walled enclosures: Typically made of cast aluminum or stainless steel, these enclosures are able to absorb and contain the pressure generated by an internal explosion.

- Sealed joints and gaskets: Joints, covers, and seals are carefully engineered to ensure they remain explosion-proof under operational conditions, with tight tolerances to prevent even small flames or sparks from leaking outside.

2. Compliance with Standards and Certifications

Explosion-proof instruments must comply with various international standards and certifications to ensure they meet the stringent safety requirements necessary for hazardous environments. Some of the most common certifications include:

- IECEx (International Electrotechnical Commission Explosive Atmospheres): This global standard ensures that equipment meets the safety requirements for use in explosive atmospheres.

- ATEX (Atmosphères Explosibles): A European certification that sets guidelines for equipment used in explosive atmospheres within the European Union.

- CSA (Canadian Standards Association): This North American standard regulates explosion-proof and flameproof equipment for use in hazardous locations.

These certifications often require the equipment to undergo rigorous testing, including pressure testing and temperature testing, to confirm its safety in extreme conditions.

3. Suitability for Hazardous Areas

Explosion-proof instruments are designed for hazardous zones, which are classified based on the likelihood of the presence of explosive atmospheres. For example:

- Zone 0: An environment where explosive gas is continuously present.

- Zone 1: An area where explosive gases are likely to occur under normal operating conditions.

- Zone 2: An area where explosive gases are not likely to occur, but if they do, they will only persist for a short period.

Similarly, dust hazards are classified as Zone 20, Zone 21, and Zone 22 depending on the frequency and duration of the presence of combustible dust.

4. Electrical Safety Mechanisms

Explosion-proof instruments use various safety mechanisms to control electrical energy. This includes isolating electrical components and minimizing the power output to levels that are incapable of igniting a flammable atmosphere. Some key electrical safety features include:

- Flameproof enclosures: These enclosures contain any internal explosions and prevent them from igniting the external atmosphere.

- Intrinsic safety: In some cases, explosion-proof instruments are designed to limit the electrical energy within the device to a level that is insufficient to ignite an explosive atmosphere. This is common for sensors and measurement instruments that operate in hazardous locations.

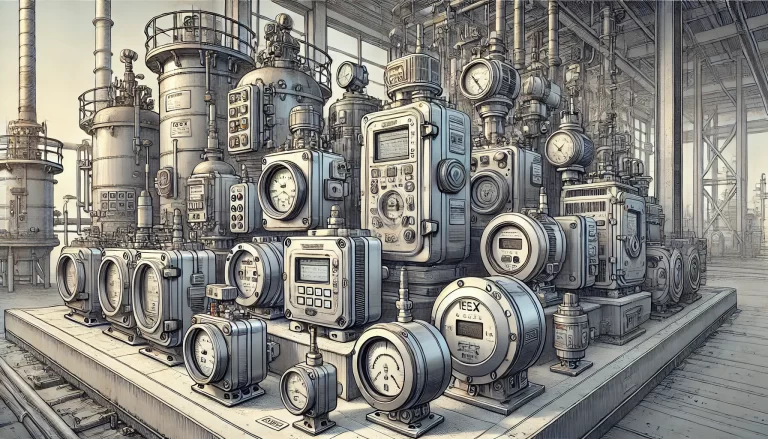

Types of Explosion-Proof Instruments

1. Explosion-Proof Pressure Transmitters

Pressure transmitters are commonly used in industries such as oil and gas and chemical processing, where precise pressure monitoring is essential for both safety and efficiency. Explosion-proof pressure transmitters are designed to function in hazardous locations while ensuring that any internal malfunction, such as short circuits, do not cause an explosion. These transmitters often feature robust, sealed enclosures that prevent the ignition of external gases.

2. Explosion-Proof Temperature Sensors

Temperature sensors, such as thermocouples and RTDs (Resistance Temperature Detectors), are critical for monitoring process conditions in hazardous environments. Explosion-proof temperature sensors are encased in sturdy, flameproof housings that ensure any temperature fluctuations within the device do not lead to an external fire or explosion. These sensors are particularly useful in refining, petrochemical, and pharmaceutical plants.

3. Explosion-Proof Flow Meters

Flow meters are widely used in industries to measure the flow rate of liquids and gases. In explosive atmospheres, explosion-proof flow meters are essential for preventing accidental ignitions. These devices feature sealed, explosion-proof housings and are often used in conjunction with other safety systems to maintain operational integrity in environments with flammable gases.

4. Explosion-Proof Liquid Level Meters

Liquid level meters are used to monitor the height of liquid in storage tanks, pipelines, and reservoirs. Explosion-proof liquid level meters ensure that monitoring occurs safely even in hazardous areas. These devices are commonly employed in industries dealing with volatile chemicals or fuels, ensuring that even in the event of a malfunction, no ignition occurs.

Maintenance and Operation of Explosion-Proof Instruments

Maintaining explosion-proof instruments requires specialized training, as these devices need to be serviced and inspected without compromising their safety features. The following precautions are necessary during operation and maintenance:

- Isolate power: Before performing any maintenance work, the power to the instrument must be isolated to prevent accidental ignition.

- Inspection of seals and gaskets: Regular inspection of the device’s seals, gaskets, and enclosures is essential to ensure that they remain intact and do not allow any leaks or sparks.

- Certified personnel: Only personnel who have been trained and certified to work on explosion-proof equipment should handle maintenance tasks. This minimizes the risk of mishandling and ensures adherence to safety protocols.

Applications of Explosion-Proof Instruments

Explosion-proof instruments are used in a variety of industries and applications, such as:

- Oil and Gas: For monitoring pressure, temperature, and flow rates in refineries, pipelines, and offshore drilling rigs.

- Chemical Processing: To ensure safe operations in environments with volatile chemical reactions and flammable gases.

- Pharmaceutical Manufacturing: Where combustible dust and gases may be present during the production of drugs and chemicals.

- Mining: To safely monitor and control equipment in underground mines where explosive gases like methane can be found.

Benefits of Explosion-Proof Instruments

- Enhanced Safety: The primary benefit is the prevention of accidents in hazardous environments. By containing potential ignition sources, these devices significantly reduce the risk of explosion.

- Durability: Explosion-proof instruments are built to withstand extreme conditions, from high pressure to corrosive environments, ensuring longevity and reliability.

- Compliance and Confidence: Using certified explosion-proof equipment ensures compliance with regulatory standards, giving companies confidence in their operational safety.

Conclusion

Explosion-proof instruments play an indispensable role in ensuring the safety of operations in hazardous environments. By preventing internal ignition sources from triggering external explosions, they safeguard both personnel and infrastructure. These instruments, with their rugged design, adherence to strict standards, and versatility across multiple industries, remain a critical component of industrial safety practices. As technology advances, explosion-proof designs continue to evolve, offering even greater protection and efficiency in dangerous environments.