Introduction

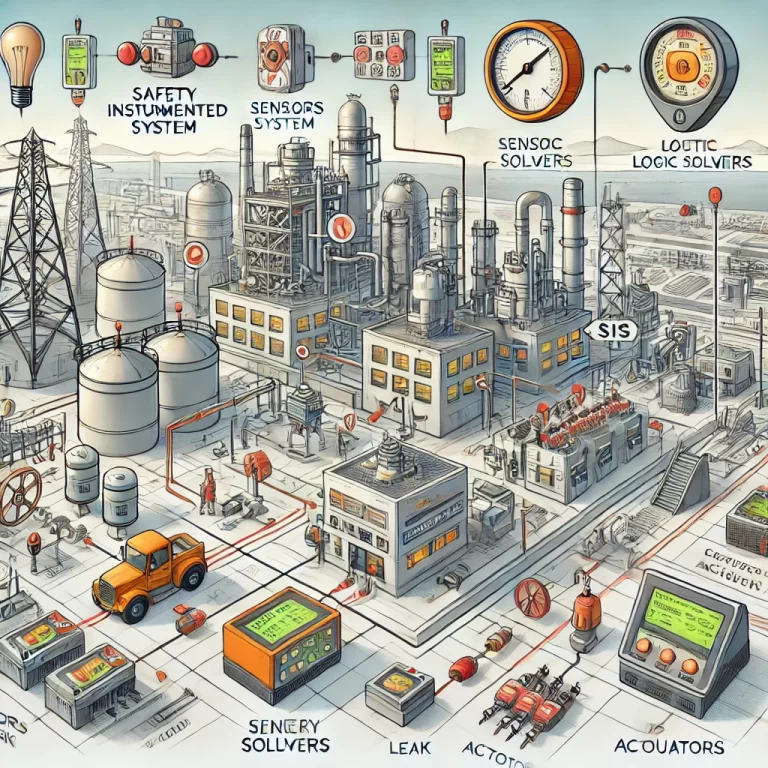

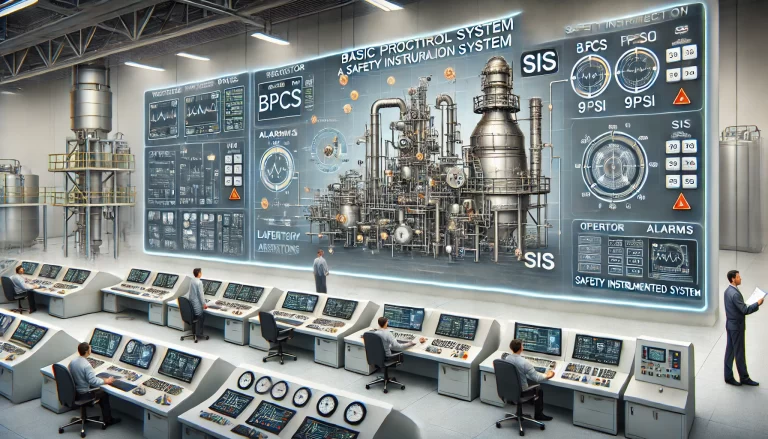

A Safety Instrumented System (SIS) is an independent system designed to prevent or mitigate hazardous events by automatically taking actions to bring a process to a safe state. Given the high risks associated with Level 1 Major Hazard Sources, determining whether an SIS is necessary requires careful evaluation of regulatory requirements, risk assessment results, and industry best practices.

1. Regulatory Considerations

Regulatory frameworks often define the necessity of an SIS based on the hazardous nature of the process, the substances involved, and the potential consequences of failure. In China, the following regulations and standards apply:

GB 30871-2022 (Safety Regulations for Special Operations in Hazardous Chemical Enterprises) mandates strict safety measures for hazardous chemical enterprises, where SIS may be required.

GB/T 21109-2007 (Chemical Industry Safety Instrumented System Design Specification) provides guidelines on the implementation of SIS in chemical enterprises.

Emergency Management Directives mandate that major hazard sources require sufficient protective measures, which may include SIS if other controls are insufficient.

Additionally, international standards such as IEC 61511 (Functional Safety – SIS for the Process Industry Sector) and OSHA PSM (Process Safety Management) in the U.S. also emphasize the role of SIS in managing process hazards.

2. Risk Assessment and SIL Determination

The need for an SIS depends on the risk assessment results, typically following methodologies such as:

Hazard and Operability Study (HAZOP)

Layer of Protection Analysis (LOPA)

Quantitative Risk Assessment (QRA)

Failure Modes and Effects Analysis (FMEA)

A Safety Integrity Level (SIL) assessment helps determine if an SIS is required. The key considerations include:

Severity of Consequences: If failure could result in catastrophic consequences (e.g., explosion, toxic release, or widespread fire), SIS is likely required.

Likelihood of Hazardous Events: If existing safety layers (e.g., alarms, operator interventions, mechanical safety devices) cannot adequately reduce risk, SIS may be necessary.

Tolerable Risk Levels: If the risk is higher than the acceptable threshold, additional layers such as SIS must be implemented.

SIS is typically required if the process risk assessment results indicate a SIL 1–4 level, where:

SIL 1: Low to moderate risk, but requires additional controls.

SIL 2: Moderate to high risk; SIS is often required.

SIL 3: High risk, necessitating an SIS with stringent reliability.

SIL 4: Extremely high risk, requiring the highest level of SIS reliability.

3. Industry Best Practices and Applications

SIS is widely used in industries handling hazardous chemicals, particularly in:

Petrochemical Plants: To prevent overpressure, leaks, and explosions.

Chemical Processing Facilities: To control reactions that could lead to thermal runaway.

LNG Terminals: To mitigate gas leaks and vapor cloud explosions.

Oil Refineries: To ensure safe shutdown during process upsets.

Pharmaceutical Industry: To prevent contamination and hazardous reactions.

Typical SIS functions in these industries include:

Emergency Shutdown (ESD) Systems

High Integrity Pressure Protection Systems (HIPPS)

Fire and Gas Detection Systems (FGS)

Overfill Protection for Storage Tanks

4. Alternative Protection Measures

Not all Level 1 Major Hazard Sources require an SIS if alternative protection measures provide sufficient risk reduction, such as:

Passive Safety Barriers: Physical containment systems, explosion-proof enclosures.

Active Protection Systems: Pressure relief valves, automatic fire suppression.

Enhanced Procedural Controls: Operator training, strict operating procedures.

If these measures effectively reduce the risk to an acceptable level, an SIS may not be required. However, if these are insufficient, an SIS becomes a necessary additional layer of protection.

5. Conclusion: Is SIS Required for a Level 1 Major Hazard Source?

The decision to implement an SIS depends on:

Compliance with safety regulations

Results of risk and SIL assessments

Existing safety measures and their effectiveness

Potential consequences of process failures

In cases where a Level 1 Major Hazard Source poses high-risk scenarios with severe consequences, an SIS is typically required to enhance process safety and reduce catastrophic risks. Organizations should conduct detailed risk assessments and follow regulatory and industry best practices to determine the necessity of SIS in their specific operations.