From Weekly Instrument Replacement to Over a Decade of Stable Operation — A Classic Low-Cost Retrofit in a Harsh Chemical Environment

📌 Background

In a low-temperature methanol wash unit used in coal gasification downstream processing, an external level transmitter was originally installed to measure the acidic gas condensate in a stripper separator. However, just six months into operation, the instrument began experiencing frequent failures — mainly diaphragm corrosion and deformation.

Due to high replacement costs and long lead times for gold-plated diaphragm transmitters, traditional upgrades proved impractical. Surprisingly, a simple external displacer-type level transmitter retrofit solved the issue and has ensured stable operation since December 2009.

🏭 Process Overview

The low-temperature methanol wash system removes CO₂, H₂S, and other acid gases from syngas (CO + H₂) at a processing capacity of 100,000 Nm³/h. The stripper column uses low-pressure steam to strip residual impurities such as NH₃, CO₂, and HCN from the condensate.

A level transmitter was installed on the separator to monitor the level of acidic gas condensate, but within months of operation, it became a recurring point of failure.

🔍 Problem Diagnosis

➤ Original Instrument Configuration:

Type: Differential pressure transmitter with dual flanges

Material: Diaphragm made of 316L stainless steel

Power: Two-wire system

Commissioned: October 2008

➤ Failure Symptoms:

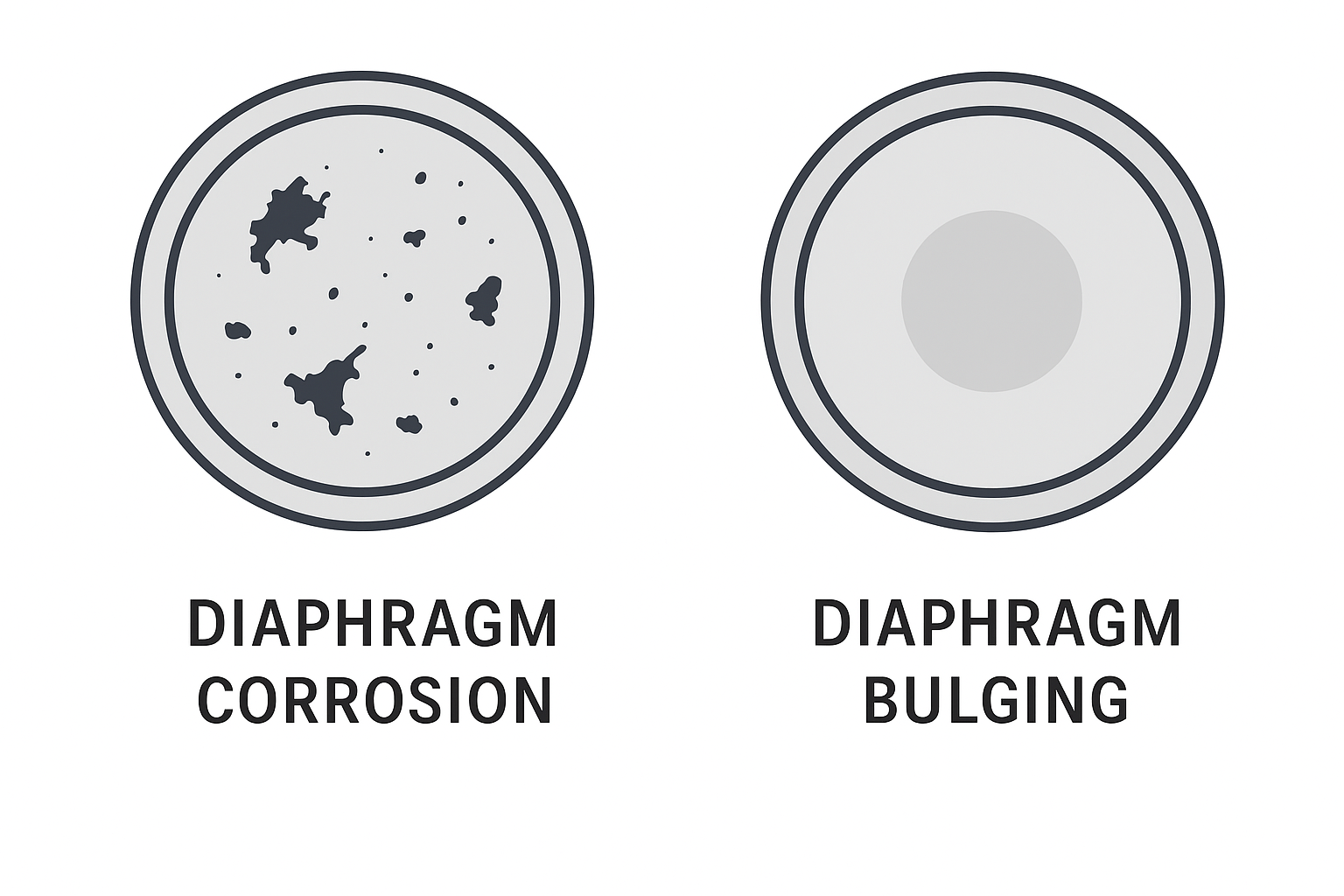

Severe corrosion on the liquid side diaphragm

Bulging deformation on the gas side diaphragm

Some diaphragms failed in less than one week

Replacements were frequent but short-lived

➤ Root Cause Analysis:

Through joint inspection with the process engineering team, it was found that:

The liquid phase contained high concentrations of H₂S, a strong corrosive agent.

The gas phase had a high hydrogen content, leading to hydrogen permeation and bulging of the diaphragm under pressure.

🔧 Retrofit Solution: External Displacer-Type Level Transmitter

➤ Reason for Selection:

Gold-plated diaphragm transmitters were ideal but expensive and hard to procure.

The displacer transmitter, with an Inconel 600 torque tube, could effectively isolate the process fluid and resist corrosion.

Spare units were readily available, and installation space was sufficient.

➤ Initial Installation Issue:

After one month of operation, the measurement started to drift significantly. Inspection revealed crystallized ammonium salts had accumulated on the inner wall and torque tube.

🧪 Progressive Modifications

Cleaning and Reinstallation:

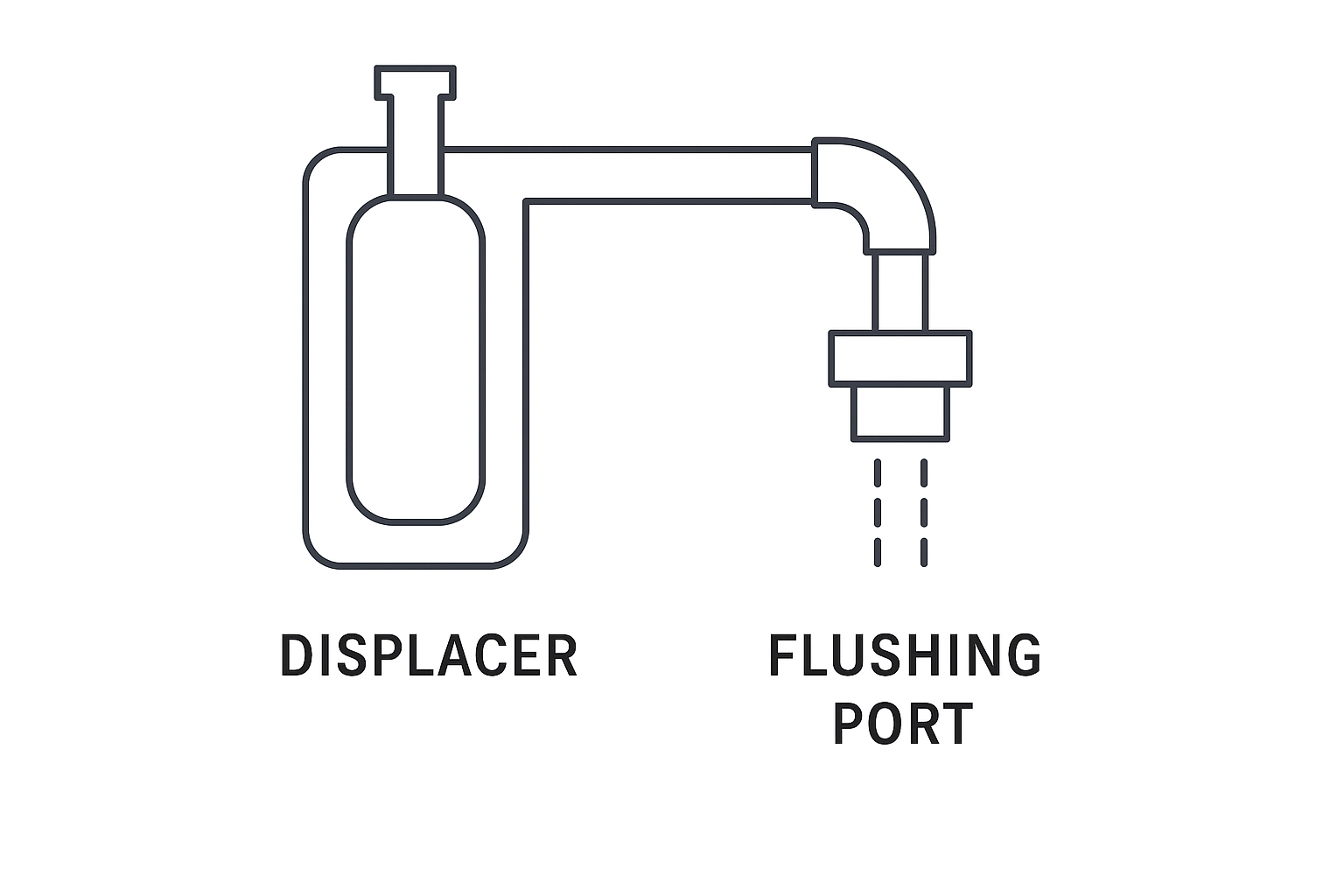

Added a flushing port on the top flange.

Used low-pressure steam for intermittent flushing.

Issue Recurrence:

Residual crystallization persisted near the torque tube.

Flushing port repositioned to the end of the displacer head, aligned with the torque tube.

Final Optimization:

Steam flushing remained ineffective.

Switched to hot condensate (~90°C water) as the flushing medium.

This final improvement effectively eliminated buildup and restored reliable measurement.

✅ Outcome

Since the final retrofit was completed in December 2009, the modified displacer-type level transmitter has operated continuously and stably, without any major maintenance needs or failure events.

📘 Takeaways & Engineering Insight

Selecting the right material and structure for corrosive and hydrogen-rich environments is more effective than blindly pursuing high-end specifications.

Practical field testing and iterative flushing optimization can dramatically enhance equipment reliability.

Low-cost retrofits, when thoughtfully executed, can produce long-term cost savings and reduce unplanned shutdowns.