Coriolis mass flowmeters have become a cornerstone in precision flow measurement. While turbine and positive displacement (PD) flowmeters have long dominated applications demanding high repeatability and accuracy, Coriolis technology represents a significant leap forward—particularly in complex or harsh process environments.

1. Working Principle of Coriolis Mass Flowmeters

Coriolis flowmeters measure mass flow directly using the Coriolis effect. Inside the sensor, fluid flows through one or more vibrating tubes. As the fluid moves through these oscillating tubes, the inertia of the moving mass causes a measurable phase shift or deflection. The amount of deflection is proportional to the mass flow rate.

✧ Key Outputs:

Mass Flow

Density

Temperature (optional)

Volume Flow (calculated)

This direct mass measurement makes them especially valuable in industries where mass—not volume—is the key parameter, such as chemical reactions, blending, or custody transfer.

2. Advantages over Turbine and PD Flowmeters

| Feature | Coriolis | Turbine | Positive Displacement |

|---|---|---|---|

| Moving Parts | ❌ None | ✅ Yes | ✅ Yes |

| Accuracy | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Measures Mass Directly | ✅ Yes | ❌ No | ❌ No |

| Viscosity Sensitivity | ❌ Not affected | ✅ Affected | ✅ Affected |

| Suitable for Slurries/Multi-phase | ✅ Yes | ❌ No | ⚠️ Limited |

| Maintenance | ⚙️ Low | ⚙️ High | ⚙️ Medium |

| Installation Sensitivity | ❌ Low | ✅ High | ✅ Medium |

Summary:

Coriolis flowmeters offer superior reliability, longevity, and multi-variable output.

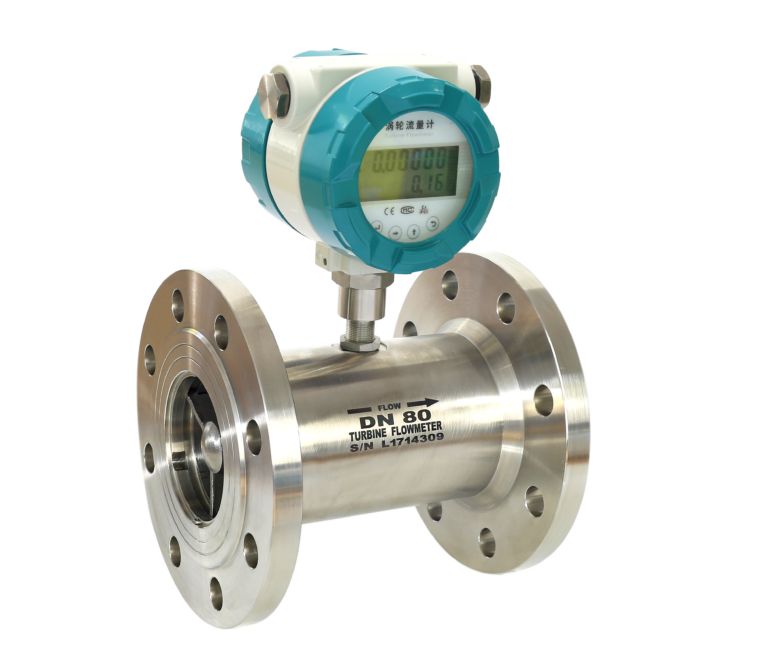

Turbine meters excel in clean, low-viscosity fluids but are sensitive to flow disturbances.

PD meters are good for viscous fluids but are mechanically complex and wear over time.

3. Typical Applications of Coriolis Flowmeters

Coriolis technology has found growing adoption in industries where accuracy, stability, and fluid characteristics are critical:

📌 Oil & Gas

Custody transfer of hydrocarbons

Measurement of crude oil with entrained gas

Additive injection systems

📌 Chemical & Petrochemical

Batch dosing with high precision

Corrosive or abrasive fluids

Density-based quality control

📌 Food & Beverage

Syrups, molasses, and dairy product measurement

Cleaning fluid flow monitoring (CIP/SIP)

Non-intrusive measurement for hygiene-sensitive processes

📌 Pharmaceutical

Solvent and reactant flow control

Highly regulated environments requiring mass accountability

GMP-compliant batch measurement

📌 Water & Wastewater (High-end applications)

Sludge measurement

Chemical dosing systems

4. Why Coriolis Is Often the “Last Resort” for Challenging Conditions

Coriolis meters are frequently chosen in the following cases:

High-viscosity fluids (bitumen, heavy oils)

Multiphase flow (gas-liquid or slurry)

Abrasion or chemical corrosion risks

High turndown ratios required

Strict process control or custody transfer regulations

When no other flow technology can maintain performance under such conditions, Coriolis is often the only viable solution.

5. Limitations to Consider

Despite their advantages, Coriolis flowmeters are not without challenges:

Higher initial cost

Heavier structure, especially for large pipe sizes

Potential sensitivity to pipe vibration or improper support

Pressure drop may be higher due to internal tube geometry

That said, for many critical applications, the return on investment is quickly justified by the reduced maintenance, downtime, and exceptional accuracy.

🔚 Conclusion

Coriolis mass flowmeters represent a transformational technology in modern process control. With their ability to provide direct, highly accurate mass flow readings, measure multiple parameters simultaneously, and perform reliably in harsh conditions, they are increasingly viewed as the gold standard in flow measurement.

While turbine and positive displacement meters still have their place, Coriolis flowmeters are often the best choice when precision, reliability, and versatility are required—especially when other flowmeters fall short.