1. Introduction

In industrial piping systems, flange connections play a vital role in ensuring mechanical strength and sealing integrity. The core element of a flange connection lies in its facing type (also referred to as the sealing face).

Different flange facings are designed to withstand varying pressure ratings, temperature ranges, and process media characteristics. Selecting the correct facing type is essential for long-term leak-free operation and compliance with international design standards.

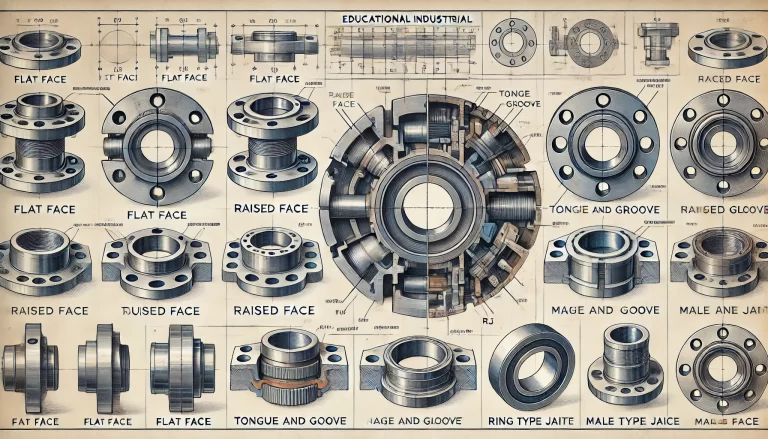

This document provides a detailed overview of the five most commonly used flange facings:

FF (Flat Face)

RF (Raised Face)

TG (Tongue and Groove)

RJ (Ring Type Joint)

MFM (Male and Female Face)

2. Classification Logic

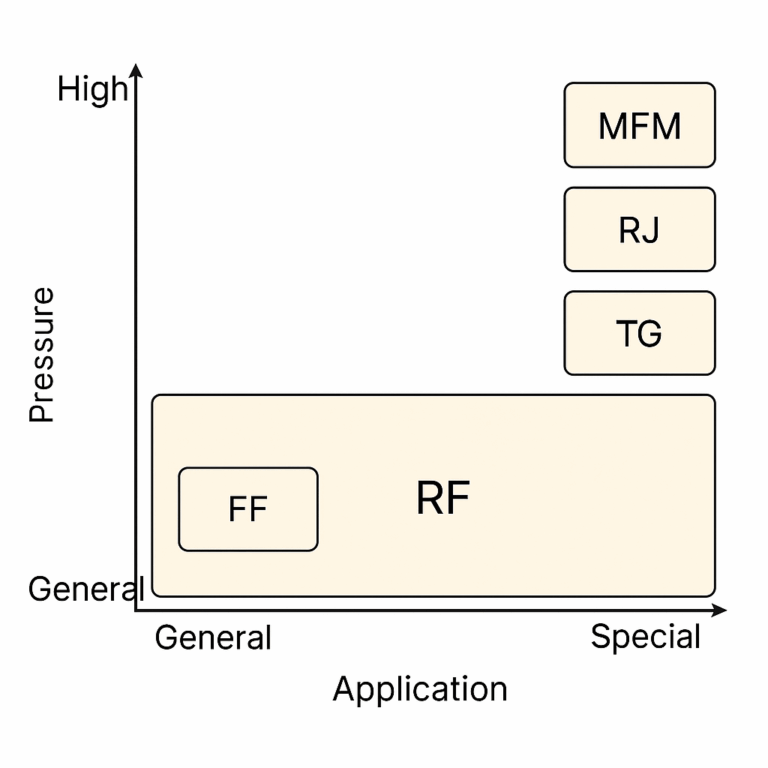

Flange facings can be categorized based on geometry and sealing principle. Selection should be guided by:

Pressure rating (low → ultra-high pressure)

Medium characteristics (toxic, flammable, corrosive, or high-purity service)

Operating temperature (cryogenic, ambient, elevated temperature)

3. Detailed Description of Flange Facing Types

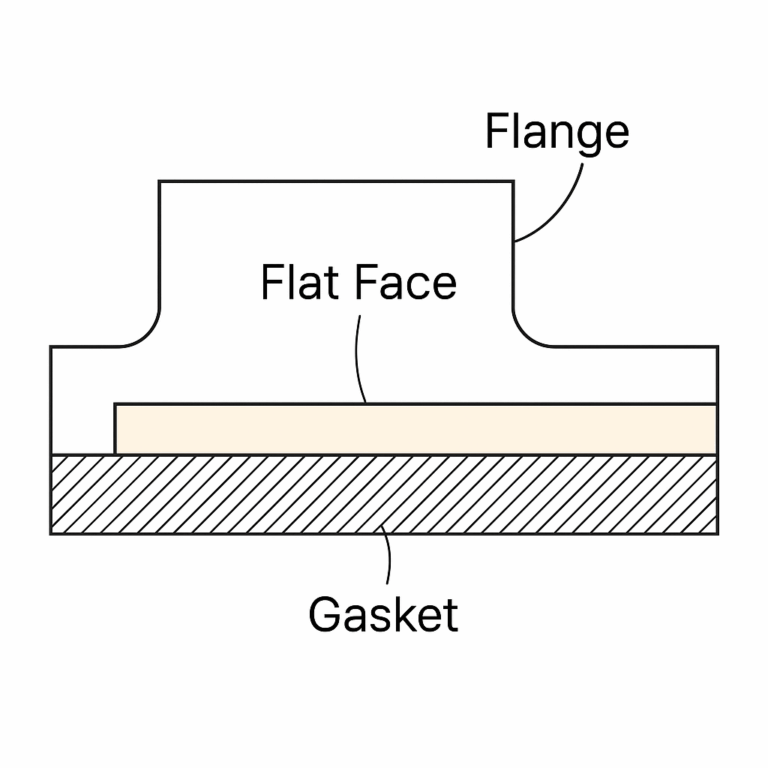

3.1 FF (Flat Face)

Appearance: A continuous flat surface across the entire flange face.

Sealing principle: Uses soft gaskets (non-metallic) compressed across a large contact area.

Advantages: Simple design, lowest cost.

Limitations: Low gasket seating stress, prone to gasket blowout at higher pressures.

Applications: Low-pressure systems (PN ≤ 16), e.g., cooling water, low-pressure air.

Standards: Commonly found in ASME B16.5 Class 150 flanges.

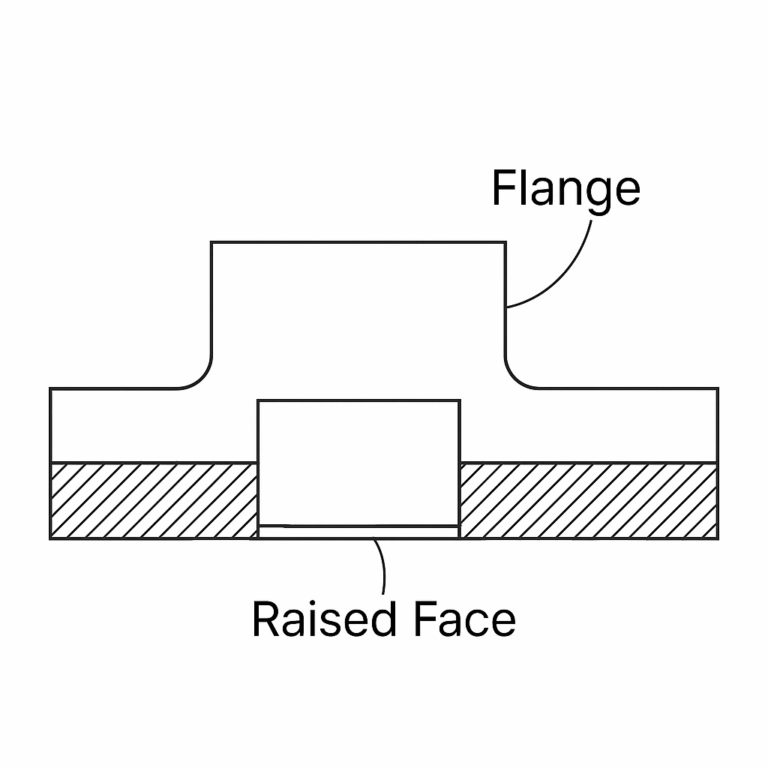

3.2 RF (Raised Face)

Appearance: A small raised annular surface (height 1.6–6.4 mm) in the flange center.

Sealing principle: Bolt force is concentrated on a smaller area, increasing gasket seating stress.

Advantages: Most widely used type, applicable from low to high pressure (PN 10–160+).

Limitations: Gasket is exposed and less protected.

Applications: Petrochemical, power plants, general process piping.

Standards: Default facing type in ASME B16.5 and EN 1092 flanges.

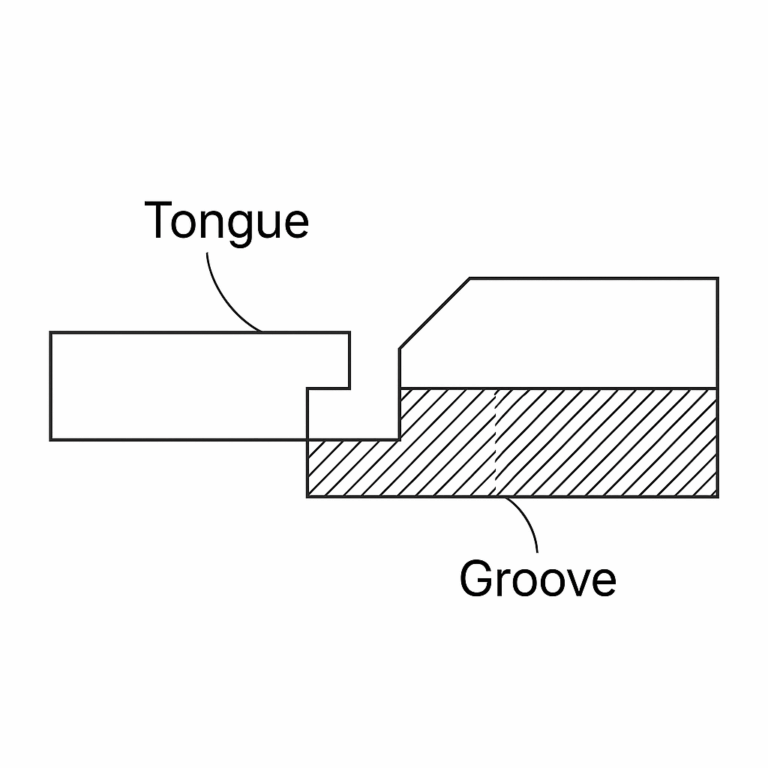

3.3 TG (Tongue and Groove)

Appearance: Pair of mating flanges — one with a raised “tongue,” the other with a recessed “groove.”

Sealing principle: Gasket is enclosed in the groove and compressed by the tongue, offering superior protection.

Advantages: Excellent sealing integrity, resistant to media blowout, thermal shock, and fire exposure.

Limitations: Higher manufacturing cost, precise alignment required, difficult to disassemble.

Applications: Hazardous, toxic, or flammable media; cyclic thermal or pressure conditions.

Standards: Used in API and EN 1092 for critical service.

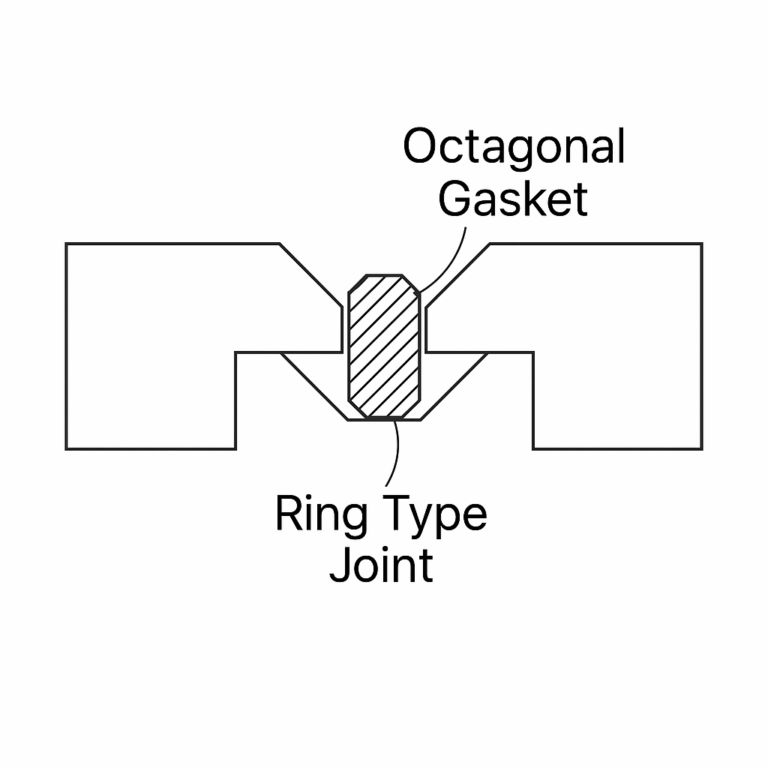

3.4 RJ (Ring Type Joint)

Appearance: Flange face has a machined trapezoidal groove.

Sealing principle: Uses soft metal rings (oval or octagonal). The ring deforms plastically when bolted, creating a metal-to-metal seal.

Advantages: Superior performance at ultra-high pressure and high temperature; resistant to blowout.

Limitations: Requires high bolt preload; flanges are heavy and expensive; gasket is typically single-use.

Applications: Oil & gas wellheads, refineries, high-pressure steam systems (PN ≥ 100).

Standards: Defined under API 6A, ASME B16.20, ASME B16.5 (RTJ facings).

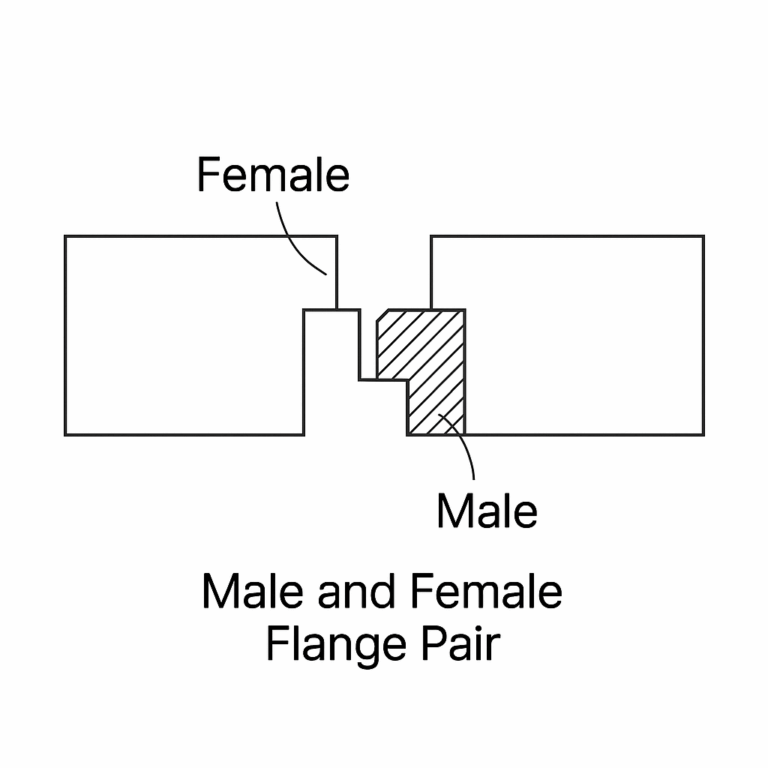

3.5 MFM (Male and Female Face)

Appearance: One flange with a raised “male” surface, the other with a matching “female” recess.

Sealing principle: Gasket is seated in the female recess and compressed by the male face.

Advantages: Provides better gasket retention than RF, easier to align than TG, reduces blowout risk.

Limitations: Male projection is prone to mechanical damage.

Applications: Medium-pressure systems, high-purity services (food, pharmaceuticals), heat exchangers, and pumps.

Standards: Specified in ASME and EN 1092 for selected industries.

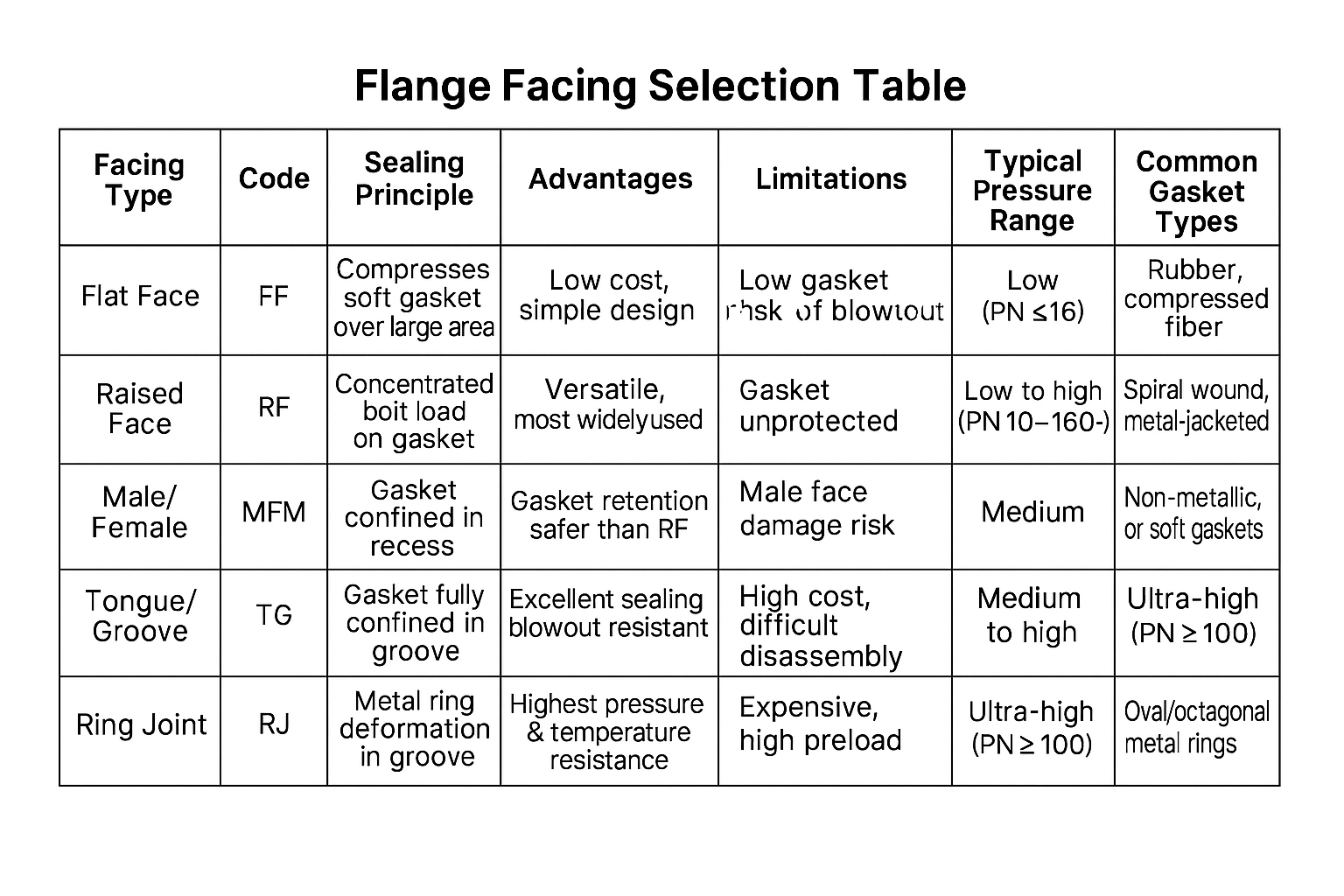

4. Quick Selection Comparison Table

| Facing Type | Code | Sealing Principle | Advantages | Limitations | Typical Pressure Range | Common Gasket Types |

|---|---|---|---|---|---|---|

| Flat Face | FF | Compresses soft gasket over large area | Low cost, simple design | Low gasket stress, risk of blowout | Low (PN ≤ 16) | Rubber, compressed fiber, asbestos-free gaskets |

| Raised Face | RF | Concentrated bolt load on gasket | Versatile, most widely used | Gasket unprotected | Low to high (PN 10–160+) | Spiral wound, metal-jacketed |

| Male/Female | MFM | Gasket confined in recess | Gasket retention, safer than RF | Male face damage risk | Medium | Non-metallic or soft gaskets |

| Tongue/Groove | TG | Gasket fully confined in groove | Excellent sealing, blowout resistant | High cost, difficult disassembly | Medium to high | Metal toothed, graphite gaskets |

| Ring Joint | RJ | Metal ring deformation in groove | Highest pressure & temperature resistance | Expensive, high preload | Ultra-high (PN ≥ 100) | Oval/octagonal metal rings |

5. Conclusion & Recommendations

Default Choice (General Service): RF (Raised Face) is the standard and safest option for most industrial applications.

Low-Pressure Utilities: FF (Flat Face) can be used in low-pressure, non-hazardous service (e.g., water, HVAC).

Hazardous/Toxic Media: TG (Tongue & Groove) and MFM (Male/Female) offer superior gasket protection and blowout resistance.

Extreme Conditions: RJ (Ring Type Joint) is indispensable in ultra-high-pressure and high-temperature environments.

Final Note: The selection of flange facings must comply with applicable design codes (ASME B16.5, EN 1092, API 6A, GB/T 9112–9124) and should be verified against process conditions and safety requirements before final approval.