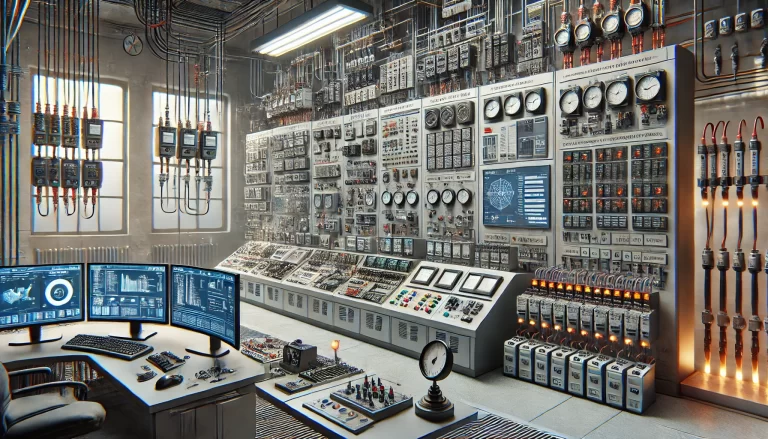

PLC (Programmable Logic Controller) control cabinets are essential in industrial automation, providing reliable and precise control over various processes. Understanding the detailed composition and operating conditions of these cabinets is crucial for ensuring their efficient and safe functioning. Below is an in-depth exploration of the main components of a PLC control cabinet and the conditions required for its optimal use.

Key Components of a PLC Control Cabinet

PLC Main Unit: The PLC main unit acts as the central processing brain of the control cabinet. It is responsible for executing user-defined programs, processing input signals, and controlling output devices. PLCs come in different types and sizes, varying in processing power and I/O capacity, to suit specific industrial needs.

2. Power Supply Module: The power supply module provides stable and regulated power to the PLC and other components in the cabinet. It typically converts standard AC (e.g., 220V) to the required DC voltage (e.g., 24V). Ensuring a reliable power supply prevents malfunctions and ensures continuous operation.

3. Input/Output (I/O) Modules:

Input Modules: These receive signals from various sensors, switches, and input devices. They can handle digital inputs (e.g., on/off signals) or analog inputs (e.g., temperature, pressure sensors).

Output Modules: These modules transmit signals from the PLC to external devices such as actuators, relays, lights, motors, and other machinery. Output modules can also handle both digital and analog signals, depending on the application requirements.

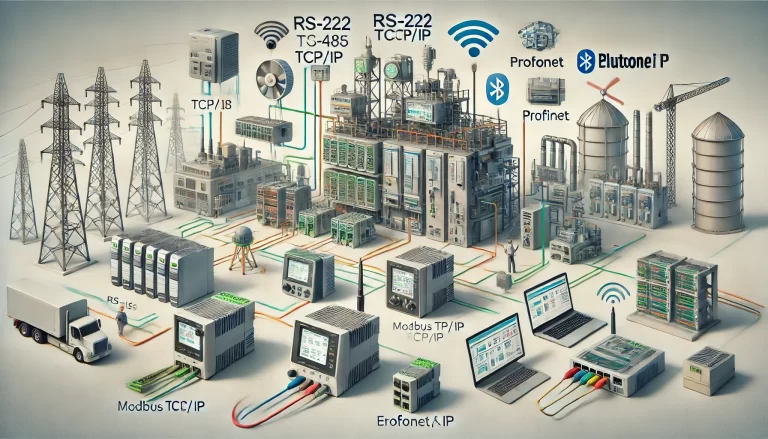

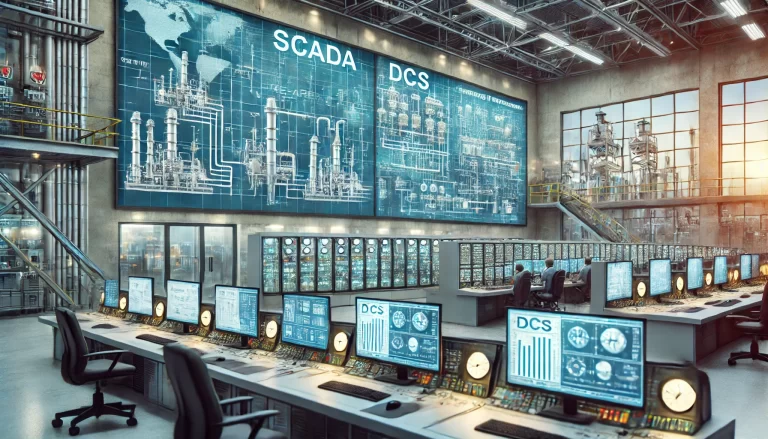

4. Communication Modules: Communication modules enable the PLC control cabinet to interact with other PLCs, computers, and supervisory systems. These modules support various communication protocols, such as Ethernet, Modbus, Profibus, and more, allowing seamless integration into larger industrial networks.

5. Relays and Contactors: Relays and contactors serve as intermediaries between the PLC and high-power devices. Relays allow the PLC to control electrical circuits by acting as electrically operated switches. Contactors are used for switching electrical circuits with higher power loads, such as motors and industrial heaters.

6. Protective Devices:

Circuit Breakers: These devices protect the electrical circuit by automatically interrupting power flow in case of an overload or short circuit.

Fuses: Fuses provide additional overcurrent protection and are designed to blow when current exceeds safe levels, thereby preventing damage to the system.

Surge Protectors: These devices shield the control cabinet from voltage spikes and surges that could occur due to lightning strikes or power grid fluctuations.

7. Terminal Blocks: Terminal blocks are used for efficient wiring and distribution within the control cabinet. They provide secure and organized connections between different components and external devices.

8. Indicating Lights and Control Buttons: LED indicators and push buttons are used for real-time status monitoring and manual control within the control cabinet. Indicating lights can signal various states such as power on, error, or operational status, while buttons facilitate manual overrides and emergency stops.

9. Cooling and Ventilation Systems: Adequate cooling systems, such as fans or air conditioning units, are installed to maintain optimal temperature levels inside the cabinet. Proper ventilation prevents overheating and ensures the reliable performance of sensitive electronic components.

10. Wiring and Cable Management: High-quality wiring and cable management solutions, including wire ducts and harnesses, are essential for the organized and safe routing of electrical cables within the control cabinet. Proper cable management minimizes electrical noise and prevents accidental disconnections.

Operating Conditions for a PLC Control Cabinet

Environmental Conditions:

Temperature: The control cabinet should be operated within a specified temperature range, typically between 0°C and 50°C. Excessive heat can lead to component failure, while low temperatures may affect performance.

Humidity: A relative humidity of up to 85% is acceptable, but the environment must be free from condensation. High humidity can cause corrosion or short circuits.

Atmosphere: The environment should be free from corrosive or flammable gases and significant dust levels. If necessary, cabinets with higher IP (Ingress Protection) ratings should be used to protect against contaminants.

Power Supply Conditions:

Stable Voltage: The power supply should match the voltage requirements of the PLC and other components, avoiding fluctuations that can lead to operational disruptions.

Uninterrupted Supply: In critical applications, an uninterruptible power supply (UPS) or backup generator may be installed to ensure continuous operation during power outages.

Cooling and Ventilation: Effective ventilation is necessary to dissipate the heat generated by the electronic components inside the cabinet. This can be achieved through passive ventilation (air vents) or active systems (cooling fans or air conditioners).

Protection and Safety:

IP Rating: The control cabinet should have an appropriate IP rating to suit its environment. For instance, an IP54-rated cabinet offers protection against dust and water splashes, while IP66-rated cabinets provide higher protection levels for more demanding conditions.

Grounding: Proper grounding is essential to avoid electrical shocks and protect against electrical faults. All metallic parts of the cabinet should be securely connected to a ground point.

Conclusion

A well-constructed and properly maintained PLC control cabinet is vital for reliable industrial automation. By understanding its key components and ensuring operation under suitable conditions, businesses can maximize the efficiency, safety, and longevity of their automated systems. Regular inspection and adherence to specified usage conditions are crucial to prevent potential issues and maintain seamless control over industrial processes.