1. Introduction

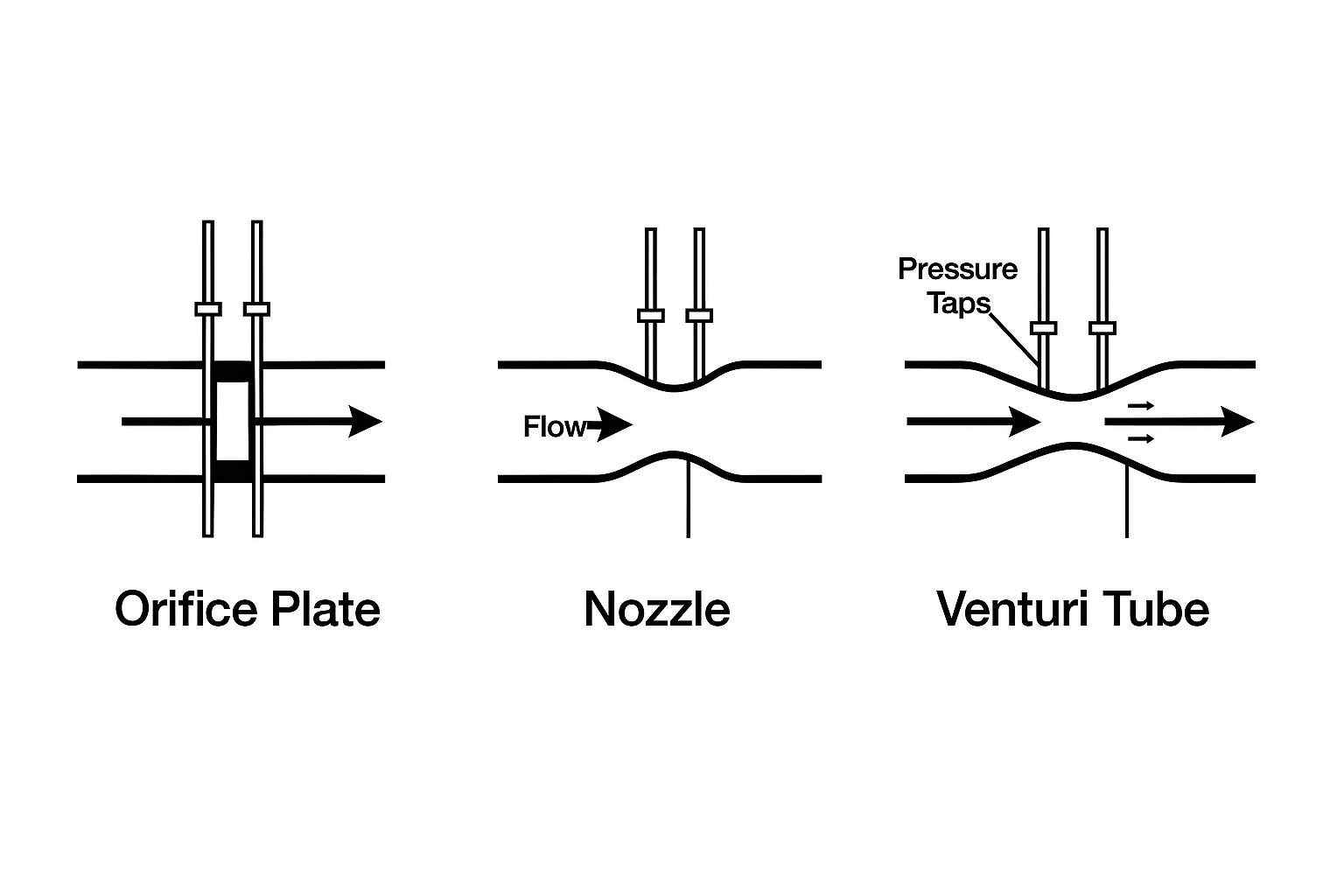

Differential pressure flowmeters are widely used in industrial fluid measurement due to their simplicity, reliability, and suitability for various process conditions. Among them, orifice plates, nozzles, and Venturi flowmeters are three of the most common types. This article compares their applicable conditions, advantages, limitations, and provides guidance for selecting the right type for specific industrial scenarios.

2. Orifice Plate Flowmeter

Typical Applications:

High-temperature, high-pressure fluids: Suitable for steam, hot air, thermal oil in power plants and petrochemical industries due to its robust structure.

Clean, low-viscosity media: Air, water, and natural gas; prone to clogging in high-viscosity or particle-laden fluids.

Standard gas metering: Common in natural gas transmission stations; composition variations may affect accuracy.

Cost-sensitive applications: Simple structure and low cost make it ideal where moderate accuracy (±0.5% to ±1%) is acceptable.

3. Nozzle Flowmeter

Typical Applications:

High-pressure, high-temperature systems: Common in main steam and feedwater pipelines of power plants, including supercritical systems.

High-accuracy requirements: When built to ASME standards, accuracy can reach ±0.5%; domestic versions may be less accurate (±4%).

Limited installation space: Compact structure with good resistance to mechanical impact; suitable for space-constrained piping.

4. Venturi Flowmeter

Typical Applications:

High-viscosity or crystallizing fluids: Ideal for chemical slurries, wastewater, or particle-laden media; diffuser design reduces clogging risk.

Low pressure loss systems: Pressure drop is only 1/5 to 1/10 that of an orifice plate; preferred for energy-saving or pump-limited applications.

Multi-industry compatibility: Used in oil, chemical, and environmental sectors, especially for corrosive, radioactive, or explosive media.

5. Comparison Table

| Parameter | Orifice Plate | Nozzle | Venturi |

|---|---|---|---|

| Accuracy | Moderate (±0.5% ~ ±1%) | High (ASME: ±0.5%) | Moderate to high (±0.5%~±1%) |

| Pressure Loss | High | Medium | Low |

| Fluid Viscosity | Low-viscosity fluids | Medium to low viscosity | High-viscosity fluids |

| High Temp/Pressure | Excellent | Excellent | Moderate (requires material enhancement) |

| Cost | Low | Medium to high | High (due to complex structure) |

| Flow Range | Medium | Wide | Very wide |

| Maintenance | Frequent (prone to clogging) | Moderate | Infrequent (less prone to clogging) |

6. Selection Guidelines

Orifice Plate: Choose when cost control is crucial and the fluid is clean and stable—ideal for water, air, and standard gas flows.

Nozzle: Best for high-precision, high-temperature/pressure process control—suitable for power generation and critical process loops.

Venturi: Recommended for challenging media such as viscous slurries or applications requiring energy efficiency—commonly used in chemical and wastewater industries.

7. Suggested Diagrams (for visual enhancement)

Consider adding the following schematic illustrations for better audience understanding:

Orifice Plate Installation Diagram

Long Radius Nozzle Cross-section

Venturi Tube with Pressure Taps and Flow Profile

Pressure Drop Comparison Curve among Three Types