Ultrasonic level transmitters are widely used in industrial process control due to their non-contact measurement, high accuracy, and easy installation. However, like all instruments, they may encounter various faults during field operation. This article summarizes the most common issues found in four-wire ultrasonic level transmitters, their causes, and practical troubleshooting solutions.

1. Power Supply and Wiring Faults

1.1 No Signal Output / Abnormal Display

Symptoms:

No display on screen

Garbled characters

No signal output to the control system

Possible Causes:

Power not connected, or polarity reversed

Supply voltage is too low (less than DC 24V) or fluctuating beyond ±10%

Solutions:

Verify the power wiring and correct the polarity

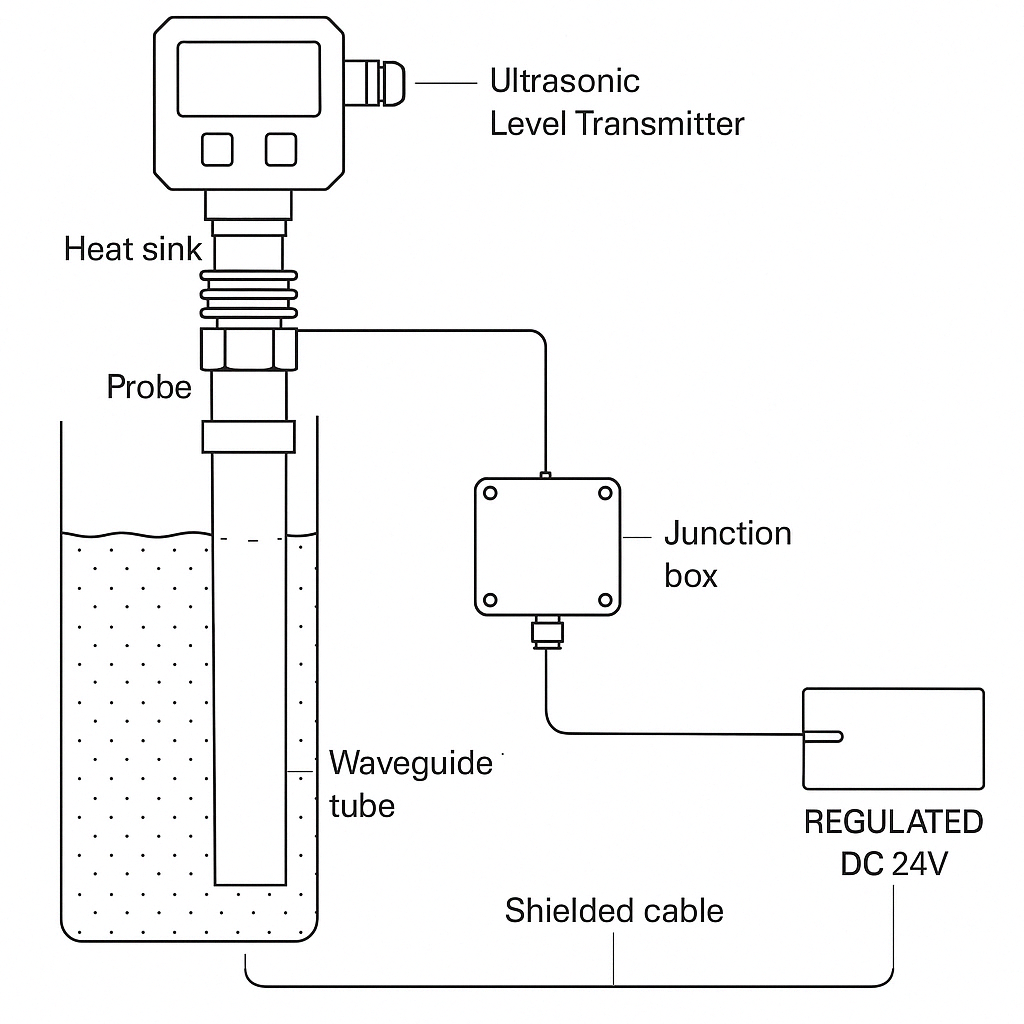

Use a regulated DC24V power supply with voltage fluctuation ≤ ±10%

1.2 Signal Line Interference

Symptoms:

Output signal fluctuates or jumps randomly

Possible Causes:

Signal cables are routed too close to power cables (distance < 20 cm)

No shielded cable used, or poor grounding (ground resistance > 4Ω)

Solutions:

Route signal cables separately using metal conduit, maintain ≥ 20 cm spacing from power cables

Properly ground the shield layer and connect the transmitter housing to an independent grounding point

2. Abnormal Measurement Readings

2.1 Fixed Reading or Large Deviation

Symptoms:

Display value is stuck and does not change

Displayed level deviates from actual value by more than ±1%

Possible Causes:

Liquid surface enters the blind zone (distance from probe to surface < 0.3 m)

Probe surface contaminated, or presence of foam/steam

Solutions:

Adjust installation height so that the maximum liquid level is above the blind zone

Clean the probe regularly; use split-type installation in high-temperature environments (cable length ≤ 15 m)

2.2 Fluctuating Readings or Delayed Response

Symptoms:

Values fluctuate frequently

Response time exceeds 2 seconds

Possible Causes:

Agitation or turbulence in the tank

Probe is installed at an angle (more than 3° from vertical)

Solutions:

Install a waveguide pipe (diameter ≥ 100 mm), or use high-frequency probe (e.g., 80 kHz) for better stability

Use a leveling tool to ensure the probe is installed vertically and aligned with the liquid surface

3. Environmental Adaptation Issues

| Working Environment | Fault Symptoms | Recommended Solution |

|---|---|---|

| High Temperature | Signal loss for distant measurements; works only at close range | Use split-type installation with heat sink (temperature ≤ 150°C); limit cable length to ≤ 15 m |

| Corrosive Media | Probe corrosion or signal weakening | Replace with PVDF or PTFE material probes; clean monthly |

| Outdoor Installation | Signal loss during rain or snow | Use IP68-rated junction boxes; seal cable entries with silicone |

4. Parameter Configuration Errors

4.1 Improper Blind Zone Setting

Symptoms:

Full-scale reading or “no echo” error

Possible Cause:

Blind zone value not adjusted according to the measuring range (e.g., for 10 m range, blind zone should be ≥ 0.5 m)

Solution:

Reconfigure the blind zone so the highest liquid level remains above the set minimum distance

4.2 Uncalibrated Sound Velocity

Symptoms:

Persistent measurement error > ±0.5%

Possible Causes:

Temperature compensation disabled

Incorrect manual sound velocity input

Solutions:

Enable automatic temperature compensation

Adjust sound velocity based on the medium’s physical properties (especially in acid/alkaline solutions)

5. Maintenance Recommendations

To reduce failure rates and ensure long-term stable operation:

Routine Calibration: Perform calibration every 6 months using a certified reference container or measurement standard.

Periodic Cleaning: Inspect and clean the probe and housing regularly, especially in environments with foam, dust, or corrosive gases.

Environmental Adjustment: Select appropriate materials and installation types (split-type, PTFE housing, etc.) according to site conditions.

Conclusion

Most faults in four-wire ultrasonic level transmitters stem from improper installation, harsh environments, or configuration errors. By applying structured diagnosis, using proper accessories (shielded cables, grounding, waveguides), and following a regular maintenance schedule, users can greatly enhance the performance and reliability of ultrasonic level measurement systems.