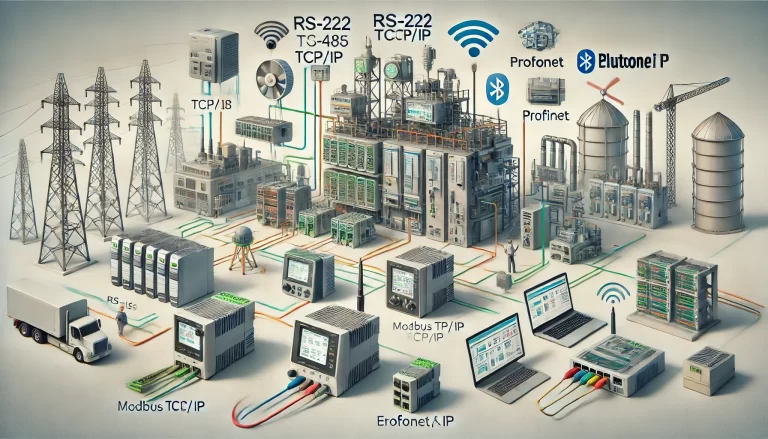

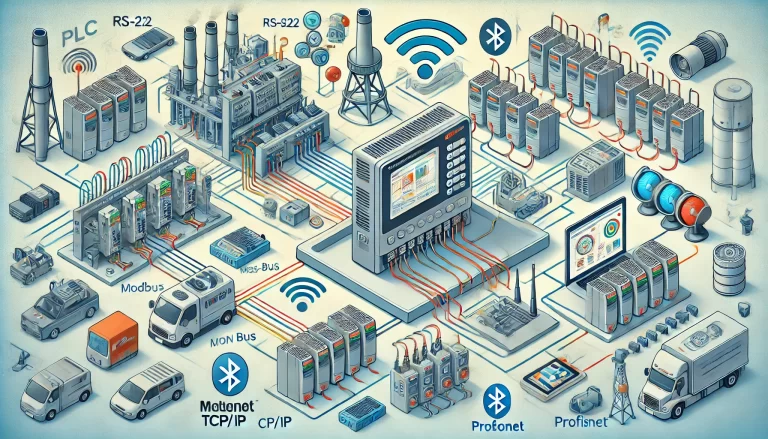

Programmable Logic Controllers (PLCs) are essential in industrial automation, where they control machinery and processes. To perform effectively, PLCs need to communicate with other devices such as Human-Machine Interfaces (HMIs), sensors, actuators, and even other PLCs. Various communication methods are available, each suited to different needs depending on factors like distance, speed, and complexity. Below is a detailed look at the most common PLC communication methods.

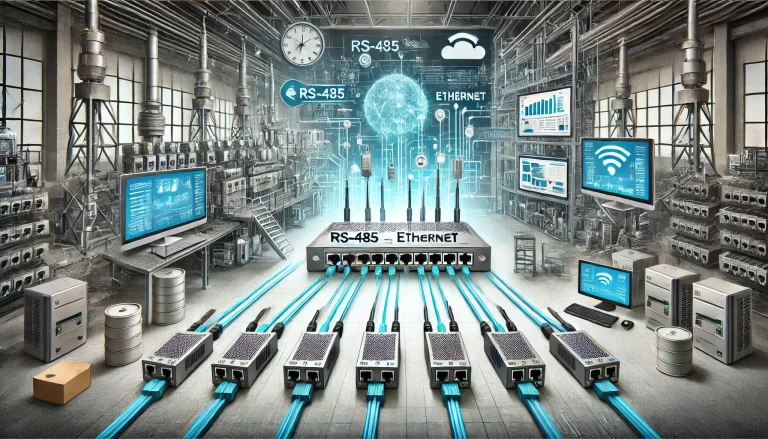

1. RS-232/RS-485 Serial Communication

RS-232 and RS-485 are two popular forms of serial communication commonly used in industrial settings, especially when connecting PLCs to local devices.

RS-232: This is a point-to-point communication protocol primarily used for short distances, typically under 15 meters (about 50 feet). It’s suitable for connecting a single device to a PLC, such as a PC or an HMI for configuration or monitoring. Due to its limited distance and lack of multi-device support, RS-232 is generally used for less complex systems, but it remains a cost-effective solution for small-scale automation tasks.

RS-485: Unlike RS-232, RS-485 supports multi-point connections, allowing up to 32 devices on a single communication line. It has a much longer range, with distances up to 1200 meters (approximately 4,000 feet). This makes it ideal for larger industrial plants where multiple PLCs and other devices need to communicate over long distances. RS-485 is also more resistant to electrical noise, making it more reliable in noisy industrial environments.

2. Ethernet Communication

Ethernet is now the backbone of most industrial communication networks due to its speed, flexibility, and capacity to handle complex systems. Ethernet-based communication protocols are widely used for PLC-to-PLC communication, PLC-to-HMI communication, and connecting PLCs to supervisory control systems. The following are some key Ethernet-based protocols:

Modbus TCP/IP: This is a variant of the Modbus protocol that runs on Ethernet networks. It uses the standard TCP/IP protocol suite for communication, which allows it to seamlessly integrate with existing IT infrastructure. Modbus TCP/IP is ideal for data exchange in industrial systems where interoperability between devices from different manufacturers is required.

Profinet: Developed by Siemens, Profinet is a real-time Ethernet communication protocol designed for high-speed, low-latency industrial automation applications. It’s commonly used in factory automation where precision timing is critical. Profinet is capable of supporting both real-time control data and non-time-sensitive data, making it versatile for complex automated systems.

EtherNet/IP: EtherNet/IP (EtherNet Industrial Protocol) is a widely used protocol for industrial automation, especially in North American industries. It allows PLCs, sensors, actuators, and HMIs to communicate over standard Ethernet, providing high-speed data transfer and easy integration with enterprise-level systems. EtherNet/IP is known for its flexibility, allowing for both real-time control and data monitoring.

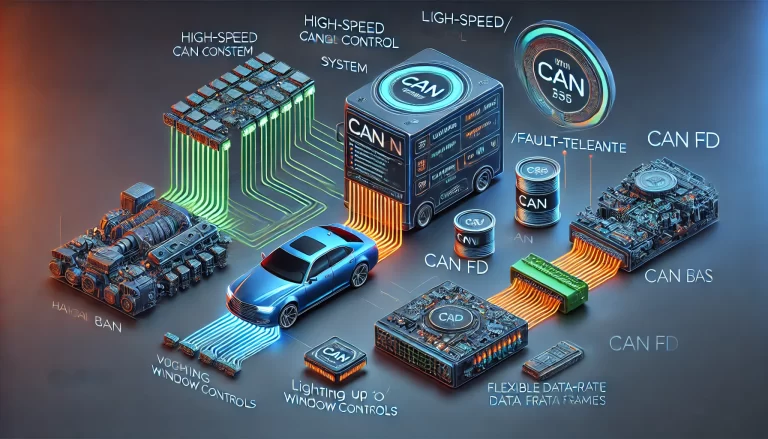

3. CAN Bus (Controller Area Network)

The CAN Bus was originally developed for the automotive industry but has since found widespread use in industrial automation. It’s a robust, multi-master communication protocol that allows various devices (controllers, sensors, etc.) to communicate with each other without needing a host computer. CAN is particularly valued for its noise resistance and reliability, especially in environments where electromagnetic interference is a concern.

In industrial automation, CAN Bus is used in applications where real-time control is required but communication speed is not as critical as in Ethernet-based systems. It’s a popular choice for decentralized automation systems, where multiple controllers need to share data and make decisions without relying on a central PLC.

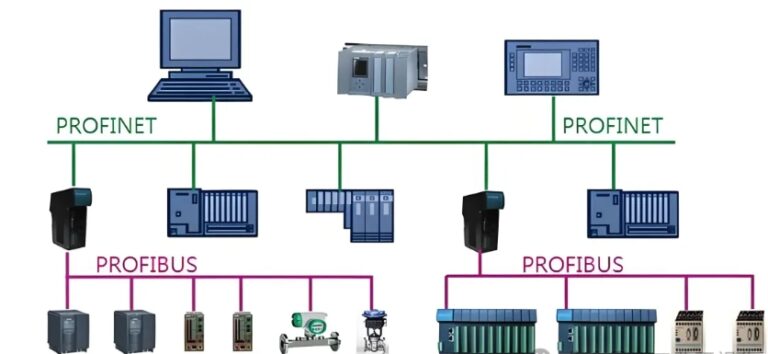

4. Profibus

Profibus is a fieldbus protocol developed by Siemens and is one of the most popular communication standards in process and factory automation.

Profibus DP (Decentralized Peripherals): This version is used for fast, real-time data exchange between PLCs and field devices like sensors and actuators. Profibus DP is widely adopted in industrial automation systems where speed and deterministic communication are critical.

Profibus PA (Process Automation): Profibus PA is designed for process industries such as oil, gas, and chemicals, where hazardous environments may be present. It’s optimized for reliable communication in explosive areas and can supply power to field devices over the communication line.

Profibus is known for its ability to handle large networks with many devices, making it a good choice for complex automation systems.

5. Modbus (RTU and TCP/IP)

Modbus is an open protocol widely used for industrial automation, known for its simplicity and ease of implementation.

Modbus RTU (Remote Terminal Unit): Modbus RTU operates over RS-232 or RS-485 and is a simple, serial-based protocol. It’s one of the most straightforward ways to enable communication between PLCs and field devices such as sensors, actuators, or HMIs. Due to its simplicity, it’s often used in smaller systems where communication speed is not a critical factor.

Modbus TCP/IP: This version of Modbus operates over Ethernet, combining the simplicity of Modbus with the speed and flexibility of Ethernet networks. It’s ideal for systems where data needs to be shared across a large network or integrated with IT infrastructure.

6. DeviceNet

DeviceNet is a network protocol based on the CAN bus, commonly used in industrial automation for communication between PLCs and I/O devices. DeviceNet is especially popular with Allen-Bradley PLCs (a Rockwell Automation brand) and offers robust communication in noisy industrial environments.

DeviceNet allows devices like sensors, actuators, and PLCs to exchange data and power over the same network cable. This simplifies the wiring and reduces installation costs. It’s especially useful in applications where multiple I/O devices need to be connected to a central PLC in a reliable and cost-effective way.

7. Wireless Communication (Bluetooth, Wi-Fi)

In some cases, wireless communication methods such as Bluetooth and Wi-Fi are used to connect PLCs to other devices. Wireless communication is beneficial in environments where wiring is difficult or impossible, such as remote locations or moving equipment.

- Bluetooth: Often used for short-range, low-power communication between PLCs and mobile devices or handheld terminals.

- Wi-Fi: Used in industrial settings where devices need to be accessed remotely or where mobile equipment needs to communicate with a PLC or supervisory control system. However, Wi-Fi is more susceptible to interference and is generally not as reliable as wired communication in harsh industrial environments.

Conclusion

The choice of communication method for a PLC depends on the specific requirements of the automation system, including factors like distance, speed, environment, and the number of devices involved. RS-232 and RS-485 are suitable for short-range or simple systems, while Ethernet-based protocols like Modbus TCP/IP, Profinet, and EtherNet/IP offer high-speed, large-scale communication capabilities. CAN Bus and Profibus provide reliable communication in more demanding environments, while wireless solutions like Bluetooth and Wi-Fi offer flexibility where wiring is impractical. Each communication method has its strengths and is chosen based on the needs of the particular application.