Introduction

A factory experienced repeated sensor failures in their vortex steam flow meters, with the failure occurring after some time despite initial checks. Each time before use, they ensured that any condensate was removed, yet the issue persisted. Is the problem with the quality of the vortex flow meter, or was there an oversight during the selection process? This article explores the key factors in selecting flow meters, especially in challenging conditions, and provides a practical approach to avoid common pitfalls.

Case Study: Repeated Sensor Failures

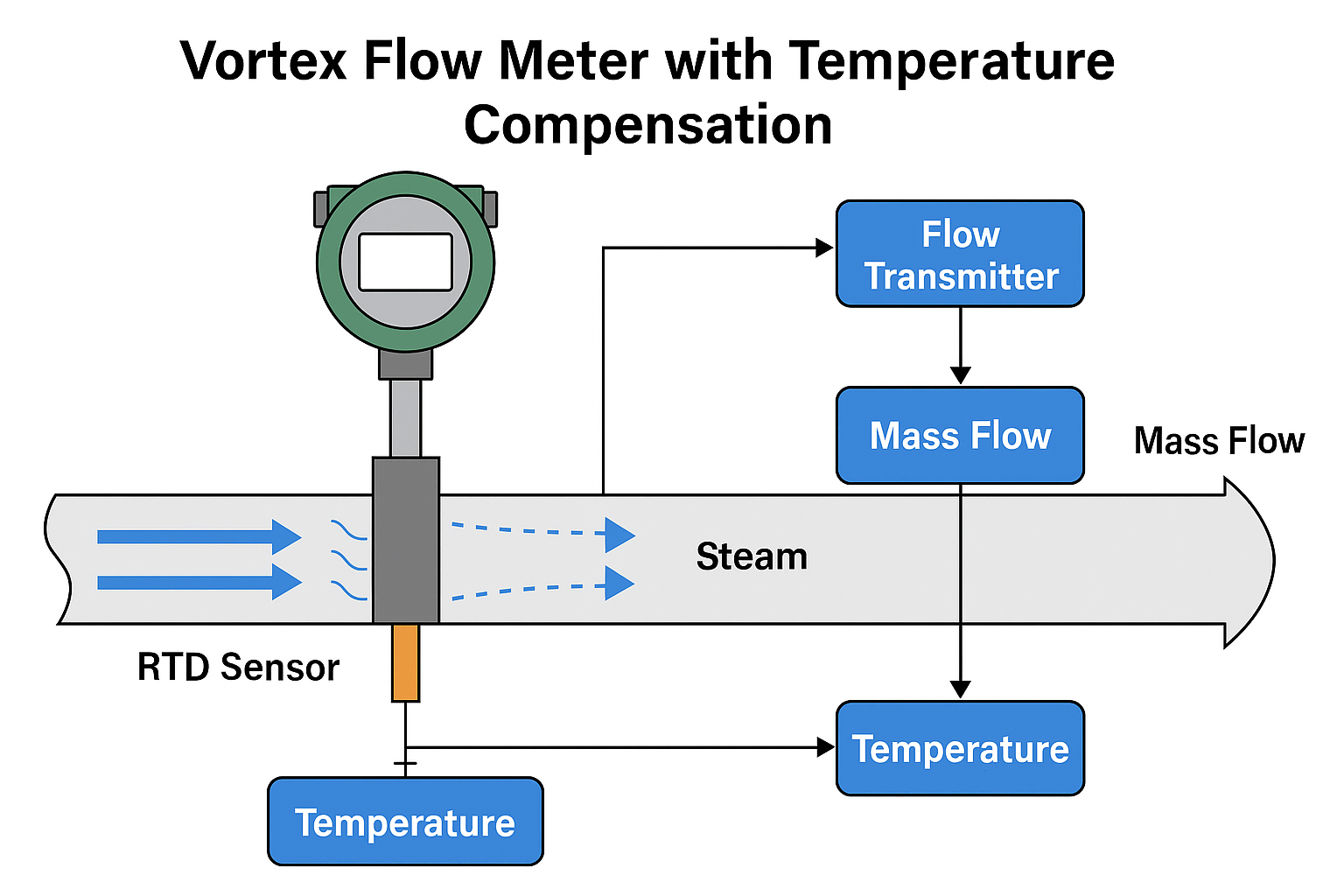

The factory faced issues where the steam pressure was 0.9 MPa, and the temperature was 180°C. Despite the installation of the vortex flow meter according to the manufacturer’s guidelines, repeated sensor failures occurred. The question arose: Was it the quality of the flow meter itself, or was the issue rooted in an incorrect selection process? This dilemma highlights the importance of a thorough selection process, considering both product quality and application-specific requirements.

Key Factors in Flow Meter Selection

Fluid Type and Characteristics

The first step in selecting a flow meter is understanding the type of fluid being measured. Key questions to ask include:Is the fluid liquid, gas, steam, or a mixture?

Does it contain solids, corrosion, or impurities?

Is the fluid conductive, corrosive, or chemically reactive?

Understanding these properties is critical for choosing the right flow meter, as different fluids require different measurement technologies.

Process Conditions

The conditions under which the flow meter will operate significantly affect its performance. These include:Temperature and pressure limits

Whether the flow is steady or pulsating

Pipe diameter and the Reynolds number of the flow

The presence of upstream or downstream straight pipe sections

Vibration levels in the system

Temperature and humidity of the environment

These factors can impact flow meter performance, and selecting the correct model can help avoid costly errors.

Installation Conditions

The installation location plays a critical role in selecting the right flow meter. Considerations include:Whether the flow meter will be installed in an open channel or a closed pipe

The pipe diameter and any changes in pipe size

The available straight pipe length upstream and downstream of the meter

The need for flow conditioners or bypasses

These factors influence how accurately and reliably the flow meter will perform.

Performance and Measurement Range

Different flow meters offer varying levels of accuracy, repeatability, and range. Key performance criteria to evaluate include:The required accuracy for your specific application

The flow range over which the meter should provide consistent accuracy

Whether the meter will be used for flow control or just for measurement

The required response time for fluctuating flow rates

It’s essential to match the performance requirements with the capabilities of the selected meter.

Economic Considerations

The total cost of ownership should be considered, which includes:Purchase costs of the meter and any secondary equipment

Installation costs, including labor and materials

Energy consumption and operational costs

Maintenance and servicing costs, as well as the availability of spare parts and after-sales support

The potential for future applications or upgrades

These factors help determine whether a particular flow meter is a cost-effective solution for the long term.

Step-by-Step Selection Process

Understand Fluid Characteristics and Application Needs

Begin by considering the physical properties of the fluid being measured and the requirements of the process. For example, is it a clean or dirty fluid? Is it non-corrosive or corrosive? Understanding these factors will help narrow down the type of flow meter required (e.g., electromagnetic, turbine, vortex, or Coriolis).Initial Instrument Type Selection

Based on the fluid characteristics and process requirements, make an initial choice for the type of flow meter. Consider whether a vortex, electromagnetic, or other meter type will meet the needs of the application.Evaluate Performance and Cost

After selecting the meter type, evaluate performance factors such as accuracy, repeatability, and operational range. At the same time, assess the total cost of ownership, including installation, maintenance, and energy consumption.Final Selection

Narrow down your options based on technical performance, cost-effectiveness, and long-term reliability. Ensure that the selected flow meter is appropriate for the specific application, considering all the factors above.

Conclusion: The Right Choice for the Right Application

Selecting the appropriate flow meter is not just about choosing a high-quality instrument. It requires a deep understanding of the fluid being measured, the operational conditions, and the performance requirements. With a comprehensive selection process, including consideration of installation conditions, fluid characteristics, and economic factors, you can avoid common pitfalls and select a flow meter that meets both technical and budgetary needs.

By paying close attention to these details, you can ensure that the chosen flow meter will provide reliable and accurate measurements, minimizing the risk of operational failures.