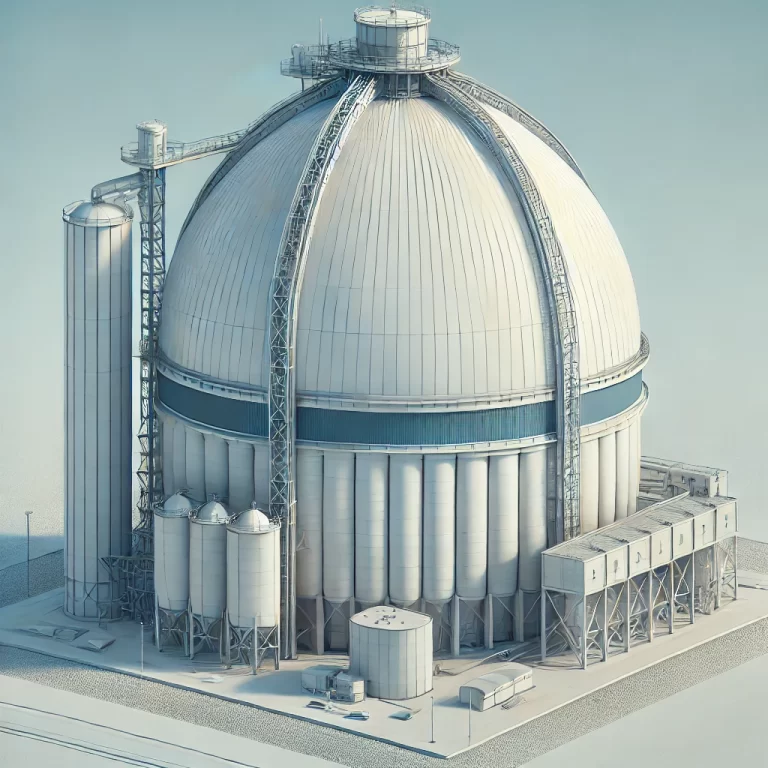

In the steel production industry, pellet ore is one of the important raw materials, and accurate measurement of its storage volume is crucial to the stable operation of the entire production.

With the development of technology, radar level meters have been widely used in the level measurement of pellet silos due to their high precision and non-contact measurement.

Radar level meters use ultra-high frequency electromagnetic waves to measure distances. They transmit microwave signals to the material surface through a transmitting antenna, and receive the reflected signals.

They calculate the distance from the material surface to the radar antenna based on the time difference or frequency change of signal transmission, and then obtain the material level.

Different from traditional measurement methods, such as weighing or ultrasonic level meters, radar level meters can work stably in high temperature, high dust, and high steam environments, and are very suitable for harsh working conditions such as pellet silos.

When using radar level meters to measure the level of pellet silos, several key factors need to be considered. Since pellets have a certain particle size and an uneven surface, this may affect the reflection of microwave signals and lead to measurement errors. Therefore, choosing a suitable type of radar level meter, such as a radar with a higher frequency band or a model with stronger signal processing capabilities, can improve the accuracy of the measurement.

The correct installation position is also an important aspect to ensure the accuracy of the measurement, avoiding the interference of obstacles in the silo on the microwave signal, and considering the dynamic changes of the pellets when flowing in the silo, the position of the radar level meter should be reasonably arranged. In actual use, the measurement stability and reliability of the radar level meter are also affected by maintenance.

Due to the complex internal environment of the pellet silo, the antenna of the radar level meter may be covered by dust, affecting the transmission and reception of the signal. Regular cleaning and maintenance are necessary to effectively extend the service life of the equipment and maintain the accuracy of the measurement.

At the same time, the use of advanced data processing techniques, such as filtering outliers and performing trend analysis, can further improve the reliability of the measurement data.

With the continuous advancement of technology, the performance of radar level meters is constantly improving. New radar level meters use higher frequency microwave signals, which can provide more precise measurement results. Powerful signal processing algorithms also enhance their adaptability under complex working conditions.

The development trend of intelligence enables radar level meters to achieve automatic calibration, remote monitoring and fault diagnosis, greatly improving the automation level and efficiency of pellet silo level measurement.