Dalian Zero Instrument Technology Co., LTD

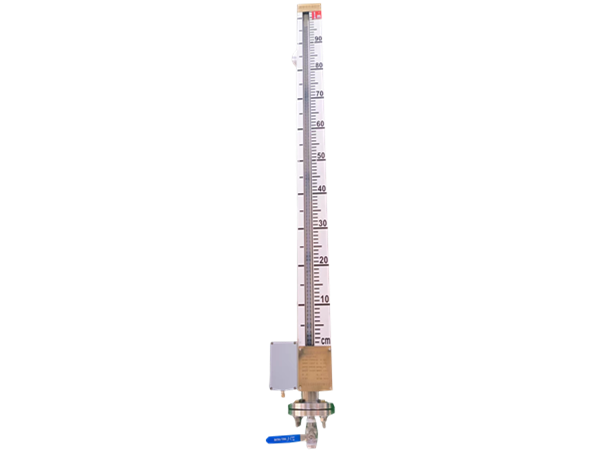

Magnetic level gauges have become essential instruments in environmental engineering due to their corrosion resistance, high reliability, and multi-functional integration capabilities. This article explores their core applications, technical advantages, real-world case studies, and common challenges encountered in various environmental treatment scenarios.

1. Core Applications in Environmental Engineering

1.1 Wastewater Treatment Systems

Regulating and Sedimentation Pools

Magnetic level gauges are installed via side- or top-mounting on regulating tanks, primary clarifiers, and secondary clarifiers in wastewater treatment plants. They provide real-time level monitoring and trigger pump control actions to prevent overflow or dry running. With corrosion-resistant materials like 316L stainless steel and PTFE linings, these gauges withstand aggressive chemical environments containing acids, alkalis, chlorides, and organic solvents.

Sludge Thickeners and Digesters

For sludge media with a solid content of 15%–30%, wide-diameter float chambers (≥DN50) and self-cleaning structures help prevent sticking and jamming. In cold environments, steam-jacketed magnetic level gauges maintain sludge fluidity, reducing annual maintenance costs by up to 35%.

1.2 Industrial Wastewater Treatment

Acid-Alkali Neutralization Tanks

In industries such as electroplating and pharmaceuticals, magnetic level gauges are used to monitor highly acidic (pH ≤2) or alkaline (pH ≥12) liquids. Their flameproof designs (Ex d IIC T6) and fully sealed construction (IP67) ensure safe and precise level control.

Oil-Water Separation Systems

Deployed in oil-containing wastewater tanks, the magnetic coupling principle allows for the detection of oil-water interfaces. Integrated magnetic switches trigger oil-recovery pumps, improving separation efficiency by approximately 20%.

1.3 Air Pollution Control Systems

Desulfurization and Denitrification Loops

In power and chemical plants, slurry circulation tanks within desulfurization towers are monitored using magnetic level gauges with Hastelloy floats. These devices resist high temperatures (≤200°C) and concentrated sulfates while transmitting real-time data to DCS systems to optimize spray control.

Alkaline Scrubber Tanks (VOCs Control)

To manage alkaline absorbent liquids in VOC scrubbers, remote-transmitting magnetic level gauges send 4–20mA signals to centralized control systems, reducing the need for manual inspections.

1.4 Solid Waste and Resource Recovery

Leachate Collection Pools

In landfill operations, magnetic level gauges are flange-mounted to cover ranges up to 15 meters. Redundant ultrasonic sensors provide cross-verification for precise level measurements in high-ammonia and saline leachate.

Reclaimed Water Storage Tanks

In reclaimed water systems, gauges with transparent polycarbonate indicator panels allow for intuitive water level visualization. The system can be linked to variable-frequency pumps for automated water reuse, achieving up to 20% water savings.

2. Technical Advantages Tailored to Environmental Engineering

2.1 Performance Highlights

Anti-Fouling Design

Internal float chamber polishing (Ra ≤0.8 μm) and scraper structures improve performance in viscous and particle-laden media.Environmental Compatibility

Certified for both intrinsic safety and explosion-proof applications, suitable for hazardous areas like biogas digesters and hazardous waste zones.Energy Efficiency

Operates without external power by using magnetic coupling to display level readings, aligning with low-power environmental equipment standards.

2.2 Functional Enhancements

Smart Automation Integration

Equipped with Reed-11 dry reed remote modules, supporting Modbus protocol for seamless PLC connectivity, enabling pump-valve linkage and fault alarms (≤50ms response time).Extreme Condition Adaptability

Thermal Protection: Electric trace heating or steam jackets prevent freezing.

High-Pressure Applications: Pressure tolerance up to 6.4MPa for RO water treatment systems.

2.3 Installation and Maintenance Features

Flexible installation options include side-mounting on underground tanks and top-mounting on sealed vessels.

Modular design enables quick replacement of floats and seals, extending maintenance intervals to 2–3 years.

3. Case Studies

Chemical Industrial Park Wastewater Plant

A PTFE-lined magnetic level gauge installed in a heavy-metal wastewater tank with pH = 1 performed continuous high-low level alarms using an SW-21 magnetic switch. This setup prevented 12 overflow incidents annually and improved O&M efficiency by 40%.

Leachate Treatment in Waste Incineration Plant

A steam-jacketed gauge (range: 0–10m) maintained stable operation under –20°C, automatically activating thermal systems when needed. Overall energy consumption dropped by 18%.

Zero-Discharge Desulfurization Wastewater at Steel Plant

A Hastelloy magnetic level gauge was installed in a crystallizer tank handling Cl⁻ at 200,000 mg/L and temperatures of 80°C. Integration with the MES system improved salt crystallization purity from 92% to 97%.

4. Common Challenges & Solutions

4.1 Complex Media Conditions

High-Viscosity Sludge:

Solution: Use hollow titanium alloy floats (density = 0.5g/cm³) and integrate high-pressure flushing ports.Crystallizing Liquids:

Solution: Inject cleaning agents regularly or add ultrasonic vibration to prevent scaling inside float chambers.

4.2 Environmental Interference

H₂S in Biogas Pools:

Solution: Use Monel alloy floats and guide rods, and switch seals to fluororubber.UV Degradation Outdoors:

Solution: Apply UV-protective coating to indicator panels, extending lifespan to 8 years.

4.3 Smart Upgrades

By integrating IoT sensors (e.g., turbidity modules) and AI-based analytics, the system enables combined water level and quality monitoring with predictive fault detection accuracy of up to 90%.

5. Conclusion

The magnetic level gauges developed by Dalian Zero Instrument Technology Co., LTD demonstrate exceptional adaptability in environmental engineering applications. As environmental standards tighten, their development continues to evolve toward high resilience, low maintenance, and intelligent connectivity. These instruments will play an increasingly vital role in pollution control, resource recycling, and smart environmental systems.