The LNG gasification and pressure regulation skid is a natural gas supply system designed for medium and small-sized enterprises and large public buildings. It is widely used for emergency gas supply, residential community gas supply, and industrial production gas supply.

The gasification and pressure regulation process consists of two main parts: the gasification of LNG and the pressure regulation (including measurement and odorization) of the gasified natural gas to the required pressure. The primary equipment for gasification is an air temperature vaporizer, which operates by utilizing the temperature difference between the environment and LNG to raise the temperature of LNG in the vaporizer pipeline, converting it into a gaseous state. The gasified LNG is referred to as NG (natural gas).

The gasification and pressure regulation process consists of two main parts: the gasification of LNG and the pressure regulation (including measurement and odorization) of the gasified natural gas to the required pressure. The primary equipment for gasification is an air temperature vaporizer, which operates by utilizing the temperature difference between the environment and LNG to raise the temperature of LNG in the vaporizer pipeline, converting it into a gaseous state. The gasified LNG is referred to as NG (natural gas).

On-Site Case Study:

In one project, to meet the gas requirements of an enterprise, a gasification and pressure regulation skid was installed at the plant site. The system has three metering pipelines, each designed to handle a flow of 100-500 Nm³/h, with two active lines and one backup line. At most, two metering pipelines can be activated simultaneously. Each metering pipeline automatically activates based on the set flow. When the actual flow exceeds 90% of the design flow, the next pipeline will automatically activate. During maintenance, operators can manually open or close the pipelines based on the on-site conditions. Each metering pipeline includes a flow meter, pressure transmitter, temperature transmitter, and flow integrator.

Customer Requirements:

- Accurately measure the gas usage and ensure uninterrupted gas supply during calibration or maintenance.

- Measure the gas flow and convert it to standard conditions.

- Ensure stable instrument performance, measuring parameters like pressure, temperature, and volume.

Solution:

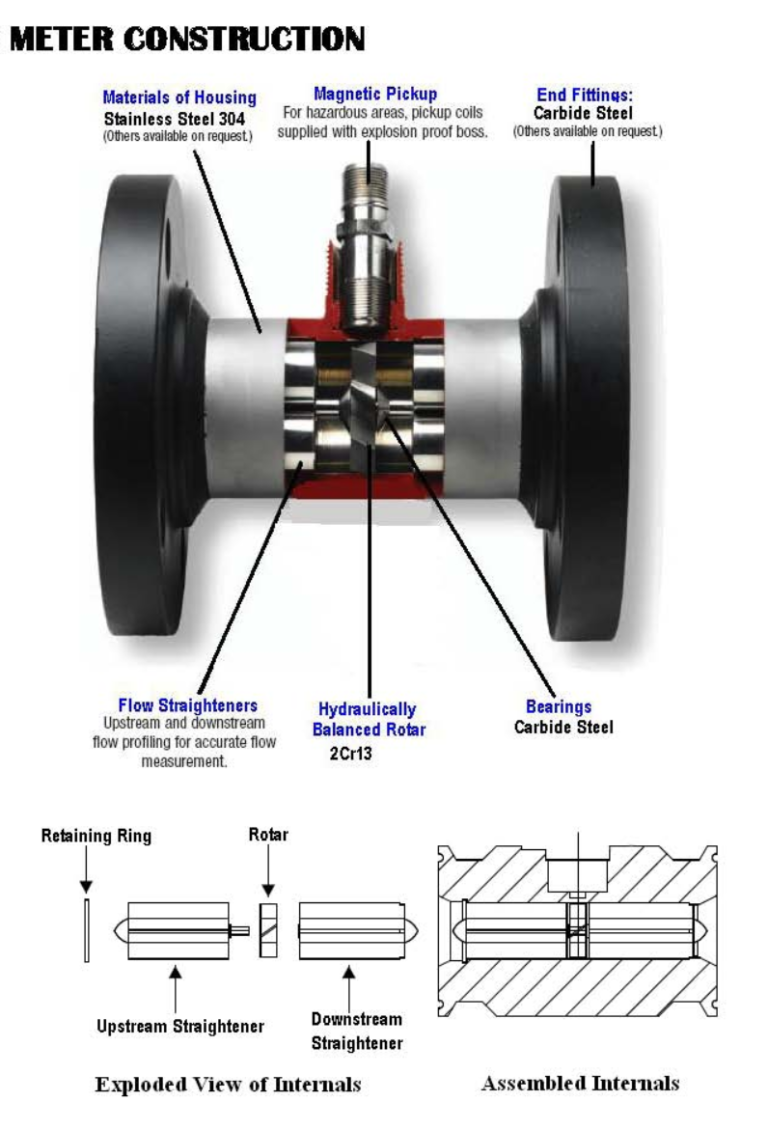

After discussions with technical staff, it was decided to use a temperature-pressure compensation integrated gas turbine flow meter with an accuracy level of 1.0. The meter’s range ratio is greater than 1:16, which meets the precision requirements for both minimum and maximum flow rates. Additionally, the flow meter is equipped with a volume corrector that automatically converts operating conditions flow to standard flow, and compensates for temperature, pressure, and compression factors. The system stores data for a year or more and automatically manages and monitors the flow. The system has two active pipelines and one bypass pipeline, ensuring uninterrupted gas supply during meter calibration or maintenance.

Customer Feedback:

The customer reported that the selected instrument matched the pipeline design, and since its installation, the meter has provided accurate flow data and stable long-term operation, reducing energy waste and cost loss due to errors and malfunctions. The meter’s compact structure and reasonable design saved installation space and simplified daily maintenance. Its intuitive interface and clear operation process significantly lowered the technical threshold and time cost for daily operations.

Recommended On-Site Products:

- LWQ Series Gas Turbine Flow Meter

- Accuracy: 1.0 level, 1.5 level

- Measurement range: from a minimum of 4 m³/h

40 m³/h to a maximum of 650 m³/h13000 m³/h - Instrument diameter: DN25~DN400

- Features intrinsic safety and explosion-proof functions, with an IP65 protection rating

- Can be equipped with NB-IoT, 4G, etc., for remote transmission via IoT

Product Features:

- Suitable for measuring non-corrosive, low-to-medium flow rate gases such as natural gas, air, nitrogen, and carbon dioxide.

- High accuracy: 1.0 and 1.5 levels.

- Wide measurement range.

- Available in various sizes: DN25 to DN400.

- Includes intrinsic safety and explosion-proof features with an IP65 protection rating.

- Supports IoT remote transmission with NB-IoT and 4G modules.