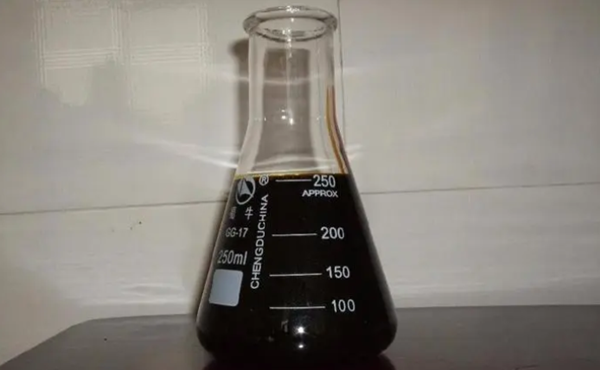

Tar, as an important chemical raw material, is widely used in many industrial processes. However, due to its unique physical and chemical properties, measuring the level of tar has always been a challenge.

Traditional level measurement methods often fail due to the high viscosity, high pollution and easy crystallization of tar. In recent years, radar level meters have begun to be used in tar level measurement due to their non-contact measurement advantages.

Tar is a complex mixture produced by incomplete combustion of coal, petroleum or other organic substances at high temperatures. It is mainly composed of aromatic hydrocarbons, aliphatic hydrocarbons, phenols and heterocyclic compounds such as nitrogen and sulfur. It has the following characteristics:

1. High viscosity: The viscosity of tar is much higher than that of water and common petrochemical products, which makes the liquid level change slowly and difficult to be captured by traditional level meters.

2. High pollution: Tar is easy to adhere to the surface of other objects, causing pollution and damage to the measuring equipment.

3. Easy to crystallize: Under low temperature conditions, some components in tar may crystallize, affecting the accurate reading of the liquid level.

4. Corrosive: The acidic components contained in tar may corrode the materials of the measuring equipment. In view of the above characteristics, radar level meter has become an ideal choice. Radar level meter measures the liquid level by emitting microwave signals and receiving their reflected waves.

It does not need to be in direct contact with the medium, so it is not affected by the viscosity, pollution and corrosiveness of the medium. In addition, the high accuracy and stability of radar level meter enable it to provide reliable level data in harsh industrial environments.

In a tar storage tank of a chemical plant, the tar level needs to be monitored in real time to ensure the continuity and safety of the production process.

Due to the special properties of tar, traditional float or pressure level gauges cannot provide accurate readings. Therefore, the plant decided to use radar level gauges for level measurement. When installing the radar level gauge, technicians took into account the high dielectric constant of tar and selected a frequency model suitable for high dielectric constant media.

At the same time, in order to reduce the impact of crystallization and attachment on the measurement, a steam purge device was installed to keep the antenna clean.

The signal processor of the radar level gauge is specially configured to adapt to the high viscosity characteristics of tar to ensure the accuracy of the measurement. After use, it was found that the radar level gauge showed good performance. It can stably provide continuous level data and maintain high accuracy even when the tar viscosity changes greatly or the temperature fluctuates.

In addition, due to the non-contact measurement principle of the radar level gauge, the maintenance workload is greatly reduced, which prolongs the service life of the equipment.

Through the analysis of tar characteristics and the introduction of actual measurement cases, it can be seen that radar level meter has significant advantages in tar level measurement.

It can not only adapt to the special physical and chemical properties of tar, but also provide accurate and stable level data, providing strong technical support for chemical production.